Introduction

In today's rapidly evolving electronics industry, electromagnetic interference and electrostatic discharge represent critical challenges that can compromise device performance, reliability, and safety. The RF Shielding Conductive Foam Gasket With Adhesive for EMI Protection ESD Safe Sponge Elastomers Die Cut Custom Applications emerges as a comprehensive solution designed to address these complex technical requirements. This advanced shielding material combines superior conductivity with flexible foam properties, delivering exceptional electromagnetic interference suppression while maintaining electrostatic discharge safety protocols. As electronic devices become increasingly sophisticated and compact, the demand for reliable EMI protection solutions continues to grow across telecommunications, automotive, aerospace, and consumer electronics sectors.

Modern electronic systems operate within increasingly congested electromagnetic environments, where unwanted interference can disrupt critical functions and degrade overall performance. Our conductive foam gaskets represent a paradigm shift in EMI shielding technology, offering engineers and designers a versatile material that adapts to complex geometries while maintaining consistent electrical properties. The integration of adhesive backing eliminates the need for additional mounting hardware, streamlining assembly processes and reducing manufacturing complexity for electronics manufacturers worldwide.

Product Overview

The RF Shielding Conductive Foam Gasket With Adhesive for EMI Protection ESD Safe Sponge Elastomers Die Cut Custom Applications represents a sophisticated engineered material specifically formulated for demanding electromagnetic compatibility applications. This conductive elastomer combines the flexibility and compressibility of traditional foam materials with enhanced electrical conductivity, creating an effective barrier against electromagnetic interference while maintaining structural integrity under repeated compression cycles.

The foam substrate incorporates specially selected conductive fillers that create continuous electrical pathways throughout the material matrix, ensuring consistent shielding effectiveness across the entire gasket surface. The adhesive backing system provides secure attachment to various substrate materials, including metals, plastics, and composite surfaces, while maintaining removability for maintenance and rework applications. This dual-functionality approach eliminates the complexity associated with traditional mechanical fastening systems while providing superior environmental sealing capabilities.

The elastomeric properties of this conductive foam enable excellent conformability to irregular surfaces and complex geometries, ensuring optimal contact pressure distribution and consistent electrical continuity. The material maintains its shielding effectiveness across wide temperature ranges and demonstrates excellent resistance to environmental factors including humidity, UV exposure, and chemical contamination commonly encountered in industrial and outdoor applications.

Features & Benefits

Advanced EMI Shielding Performance

The conductive foam gasket delivers exceptional electromagnetic interference suppression across broad frequency ranges, making it suitable for applications spanning from low-frequency power line interference to high-frequency radio frequency emissions. The uniform distribution of conductive particles throughout the foam matrix ensures consistent shielding effectiveness regardless of compression levels or surface irregularities. This characteristic proves particularly valuable in applications where traditional metallic shielding solutions may create gaps or discontinuities that compromise overall system performance.

The material's ability to maintain electrical continuity under dynamic conditions sets it apart from rigid shielding alternatives. As electronic enclosures expand and contract due to thermal cycling or mechanical stress, the foam's elastic properties accommodate these dimensional changes while preserving critical electrical connections. This adaptability ensures long-term reliability in applications where mechanical stability and electromagnetic compatibility must coexist.

ESD Safe Properties

Electrostatic discharge protection represents a fundamental requirement in modern electronics manufacturing and handling environments. The RF Shielding Conductive Foam Gasket With Adhesive for EMI Protection ESD Safe Sponge Elastomers Die Cut Custom Applications incorporates carefully controlled conductivity levels that provide effective static charge dissipation while preventing potentially damaging current surges. This balanced approach protects sensitive electronic components during assembly, testing, and operational phases.

The ESD safe characteristics extend beyond simple static dissipation, encompassing comprehensive charge management throughout the material structure. The foam's cellular architecture creates multiple pathways for controlled charge transfer, preventing the accumulation of static electricity that could otherwise damage sensitive semiconductor devices or disrupt precision electronic circuits. This protection proves essential in applications involving high-value components or mission-critical systems where ESD-related failures could result in significant operational consequences.

Superior Adhesive Integration

The integrated adhesive system represents a carefully engineered solution that balances immediate bonding strength with long-term removability. Unlike permanent attachment methods, this adhesive technology allows for component replacement and maintenance activities without damaging substrate surfaces or leaving residual contamination. The adhesive maintains its properties across extended temperature ranges and demonstrates excellent resistance to environmental factors that commonly affect electronic assemblies.

The adhesive formulation incorporates advanced polymer chemistry that provides initial tack for easy positioning while developing full bond strength over time. This characteristic enables precise placement during assembly processes while ensuring secure attachment throughout the product lifecycle. The adhesive system also contributes to the overall environmental sealing properties of the gasket, preventing moisture ingress and contamination that could compromise electrical performance.

Applications & Use Cases

The versatility of conductive foam gaskets makes them indispensable across diverse industries and applications where electromagnetic compatibility and electrostatic discharge protection represent critical requirements. In telecommunications infrastructure, these materials provide essential EMI shielding for base station equipment, network switches, and signal processing devices that operate in electromagnetically challenging environments. The foam's ability to conform to complex housing geometries while maintaining consistent electrical properties proves particularly valuable in compact telecommunications equipment where space constraints demand efficient material utilization.

Automotive electronics applications represent another significant market segment where RF Shielding Conductive Foam Gasket With Adhesive for EMI Protection ESD Safe Sponge Elastomers Die Cut Custom Applications delivers exceptional value. Modern vehicles incorporate numerous electronic control units, infotainment systems, and communication devices that must coexist without mutual interference. The conductive foam gaskets provide effective electromagnetic isolation between these systems while accommodating the vibration, temperature cycling, and environmental exposure typical of automotive applications.

Aerospace and defense applications demand the highest levels of electromagnetic compatibility and reliability, making conductive foam gaskets essential components in avionics systems, radar equipment, and communication devices. The material's ability to maintain consistent performance across extreme temperature ranges and challenging environmental conditions makes it suitable for both commercial aviation and military applications where failure is not an option. The ESD safe properties prove particularly critical in applications involving sensitive electronic warfare systems and precision navigation equipment.

Consumer electronics manufacturers increasingly rely on conductive foam gaskets to address electromagnetic interference challenges in smartphones, tablets, gaming devices, and wearable technology. As these devices become more compact and feature-rich, the potential for internal EMI increases significantly. The foam gaskets provide effective isolation between different circuit sections while enabling the miniaturization trends that drive consumer electronics innovation.

Industrial automation and control systems represent another growing application area where electromagnetic compatibility directly impacts operational reliability and safety. The conductive foam gaskets help ensure that programmable logic controllers, variable frequency drives, and sensor systems operate without interference, even in electrically noisy industrial environments characterized by heavy machinery and power systems.

Quality Control & Compliance

Manufacturing excellence in conductive foam gasket production requires comprehensive quality management systems that address both material properties and performance characteristics. Our production facilities implement rigorous testing protocols that verify electrical conductivity, mechanical properties, adhesive performance, and environmental resistance throughout the manufacturing process. These quality control measures ensure that every batch of RF Shielding Conductive Foam Gasket With Adhesive for EMI Protection ESD Safe Sponge Elastomers Die Cut Custom Applications meets stringent specifications for electromagnetic shielding effectiveness and ESD protection.

The quality assurance program encompasses raw material inspection, in-process monitoring, and finished product verification to maintain consistent performance characteristics. Advanced testing equipment measures shielding effectiveness across relevant frequency ranges while specialized fixtures evaluate compression-deflection properties and adhesive bond strength. Environmental testing protocols subject materials to accelerated aging conditions that simulate extended service life under challenging operational conditions.

Compliance with international standards represents a fundamental requirement for global electronics applications. Our conductive foam gaskets undergo testing and certification according to relevant electromagnetic compatibility standards, ensuring compatibility with regulatory requirements in major markets worldwide. The ESD safe properties receive verification through standardized test methods that confirm controlled charge dissipation characteristics suitable for sensitive electronic applications.

Traceability systems maintain detailed records of material composition, processing parameters, and performance test results for each production lot. This comprehensive documentation enables rapid identification and resolution of any quality issues while providing customers with the confidence that their critical applications receive materials meeting specified performance criteria. Regular audits and continuous improvement initiatives ensure that quality management systems evolve to address emerging requirements and industry best practices.

Customization & Branding Options

The die-cutting capabilities integral to conductive foam gasket manufacturing enable precise customization for specific application requirements. Advanced cutting technologies accommodate complex geometries, intricate patterns, and tight dimensional tolerances that match customer specifications exactly. This customization capability eliminates the waste and imprecision associated with field modifications while ensuring optimal fit and performance in the final application.

Material thickness options provide additional flexibility for applications with specific compression requirements or space constraints. The foam substrate can be manufactured in various thicknesses while maintaining consistent conductive properties and adhesive performance throughout the material cross-section. This thickness versatility enables engineers to optimize gasket performance for specific compression loads and sealing requirements.

Shape complexity presents no limitation for our die-cutting processes, with capabilities extending to gaskets featuring multiple openings, intricate perimeters, and integrated features such as alignment tabs or mounting provisions. Computer-controlled cutting systems ensure precise reproduction of customer-supplied drawings while maintaining tight tolerances that eliminate fit and assembly issues. The precision cutting process also minimizes material waste, contributing to cost-effectiveness for high-volume applications.

Custom material formulations address specialized application requirements that standard products cannot fully satisfy. Our technical team collaborates with customers to develop optimized conductive foam compositions that balance electromagnetic shielding effectiveness, mechanical properties, and environmental resistance for specific operating conditions. This collaboration extends to adhesive selection, where different chemistry options provide enhanced performance for particular substrate materials or environmental exposures.

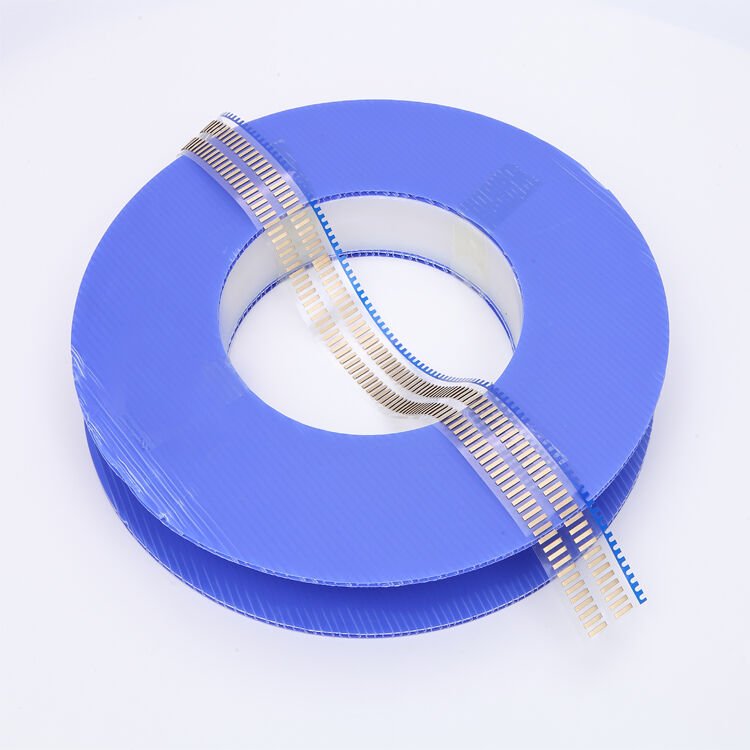

Packaging & Logistics Support

Effective packaging systems protect conductive foam gaskets during transportation and storage while facilitating efficient handling and inventory management. Our packaging solutions incorporate protective materials that prevent compression damage, contamination, and adhesive degradation throughout the supply chain. Specialized packaging configurations accommodate different gasket sizes and quantities while optimizing shipping efficiency and storage requirements.

Climate-controlled storage recommendations ensure that RF Shielding Conductive Foam Gasket With Adhesive for EMI Protection ESD Safe Sponge Elastomers Die Cut Custom Applications maintain optimal performance characteristics from manufacture through final application. The packaging systems incorporate barrier properties that protect against moisture, temperature fluctuations, and UV exposure that could otherwise degrade material properties or adhesive performance. Clear labeling systems provide essential product identification and handling instructions to prevent confusion and ensure proper application.

Logistics coordination extends beyond simple transportation to encompass inventory management support and just-in-time delivery programs that align with customer production schedules. Our distribution network enables efficient delivery to manufacturing facilities worldwide while maintaining the cold-chain requirements essential for adhesive-backed products. Flexible packaging options accommodate both prototype quantities for development projects and high-volume production requirements.

Documentation packages accompany each shipment, providing material certificates, test reports, and handling instructions that support quality assurance programs and regulatory compliance requirements. Digital tracking systems enable real-time shipment monitoring while maintaining complete chain of custody documentation from production through delivery. This comprehensive approach ensures that customers receive products in optimal condition while maintaining the documentation necessary for critical applications.

Why Choose Us

Our commitment to electromagnetic compatibility solutions spans over two decades of specialized experience in conductive materials development and manufacturing. This extensive background enables us to understand the evolving challenges facing electronics manufacturers while developing innovative solutions that address both current and anticipated future requirements. Our international presence across major manufacturing regions ensures responsive local support while maintaining consistent global quality standards that electronics manufacturers require for worldwide product deployment.

Technical expertise represents a cornerstone of our value proposition, with engineering teams that collaborate directly with customers to develop optimized EMI shielding solutions. Our application engineers possess deep understanding of electromagnetic theory, materials science, and manufacturing processes that enable them to recommend the most effective RF Shielding Conductive Foam Gasket With Adhesive for EMI Protection ESD Safe Sponge Elastomers Die Cut Custom Applications configurations for specific requirements. This technical support extends throughout the product lifecycle, from initial concept development through production optimization and ongoing performance monitoring.

Manufacturing capabilities encompass both standard product lines and specialized custom solutions that address unique application requirements. Our production facilities incorporate advanced process control systems and quality management protocols that ensure consistent material properties and performance characteristics. Investment in cutting-edge manufacturing technology enables us to maintain competitive lead times while meeting the stringent quality requirements essential for critical electronic applications.

Global collaboration with electronics manufacturers across automotive, aerospace, telecommunications, and industrial sectors provides invaluable insights into emerging trends and requirements. This broad industry exposure enables us to develop advanced materials and solutions that anticipate future challenges while addressing current application needs. Our multi-industry expertise ensures that solutions developed for one sector often provide unexpected benefits in others, creating synergistic advantages for our customers.

Conclusion

The RF Shielding Conductive Foam Gasket With Adhesive for EMI Protection ESD Safe Sponge Elastomers Die Cut Custom Applications represents a sophisticated solution for modern electromagnetic compatibility challenges in electronic systems. Its unique combination of superior EMI shielding performance, ESD safe properties, and flexible installation capabilities addresses the complex requirements of contemporary electronics applications across diverse industries. The material's ability to conform to irregular surfaces while maintaining consistent electrical properties, combined with integrated adhesive backing and precise die-cutting capabilities, provides engineers with a versatile tool for addressing electromagnetic interference challenges in innovative ways. As electronic systems continue to evolve toward greater complexity and miniaturization, this advanced conductive foam technology offers the reliability, performance, and adaptability necessary to ensure electromagnetic compatibility in demanding applications worldwide.

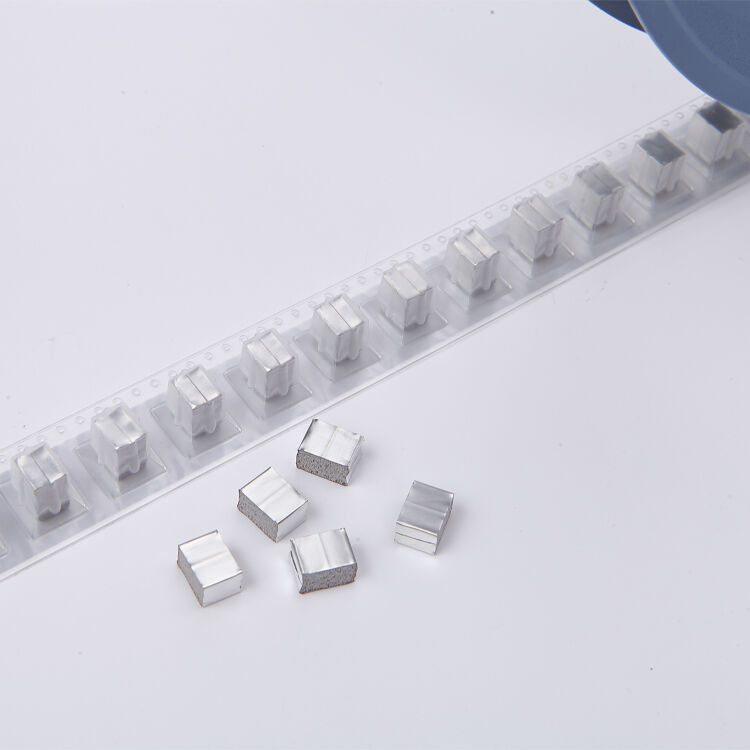

Johan ECF (Elastic Conductive Foam)

Technical Data Sheet

|

Updated: May,2021

|

||

Description

|

This grounding foam is made of high-rebound elastomer base and super thin conductive fabric or film and suitable for high requirement grounding in super thin space. Due to its unique structure, it shows low electrical resistance and stable physical properties even after tough environment test. |

||

Structure

Application

Typical Physical Properties |

The following technical information and data should be considered representative or typical only and should not be used for specification purposes. |

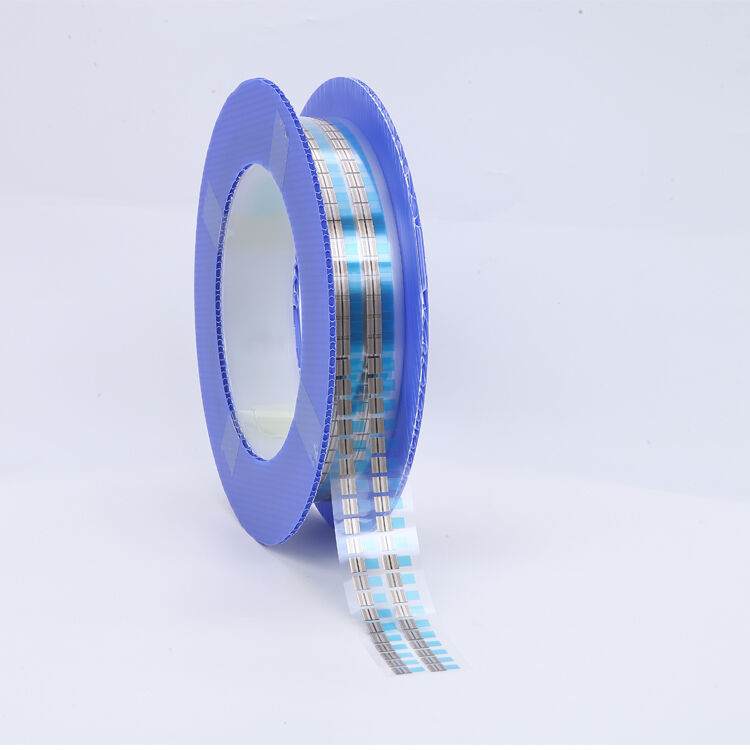

Compression Rate |

0% |

30% |

50% |

70% |

Through-Resistance(Ω) |

0.179 |

0.080 |

0.051 |

0.045 |

Compression Rate |

0% |

30% |

50% |

70% |

Through-Resistance(Ω) |

0.201 |

0.115 |

0.070 |

0.058 |

Other dimension could be customized per demand.

(Fabric/Film with Au-plating work better with high refresh rate display including LCD and provide more stable performance over time)

(Working Height: 0.20mm ECF-SF-05S3 Fabric-Ni-Plating)

(Working Height: 0.30mm ECF-SF-07S3 Fabric-Ni-Plating)

(Working Height: 0.20mm ECF-SF-05S3GP Fabric-Au-Plating )

(Working Height: 0.33mm ECF-SF-07S3GP Fabric-Au-Plating)

Company Profile

We cater primarily to the consumer electronics, communication networks, and emerging energy vehicle sectors. To back ourcommitment to quality and innovation, we have established a national production base across four strategic locations:

1. A 1,000-square-meter new material formula R&D center in Shenzhen.

2. A 2,000-square-meter innovative grounding wrapping production plant in Dongguan.

3. A 10,000-square-meter conductive shielding tape coating plant in Hunan.

4. A 1,000-square-meter magnetron sputtering continuous gold/tin plating plant in Shandong.

As the only vertically integrated integrator in China offering electroplating, coating, and processing capabilities, we strive to become a leading innovator and provider of core values within the materials industry chain. Our ultimate goal is to be a long-term trusted solution provider and partner for our customers in addressing their challenges.

System certification

Invention Patent

FAQ

We are based in Guangdong, China, start from 2011,sell to South Asia(10.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Shielding tape,Adhesive tapes,Waterproof and breathable membrane,Customized production,Raw material die-cutting

4. why should you buy from us not from other suppliers?

Shenzhen Johan Material Tech Co., Ltd. was established in 2011, and is an innovative national high-tech enterprise providing

innovative EMC (electromagnetic compatibility) grounding elastomers and customized tape solutions for the electronics indus

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency: USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken: English,Chinese