Introduction

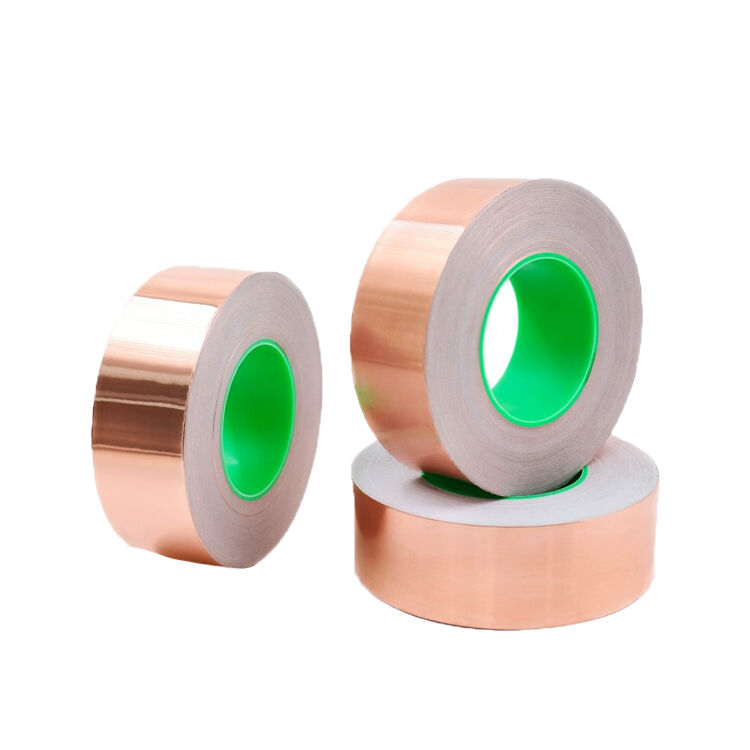

In today's rapidly evolving electronics industry, electromagnetic interference poses significant challenges to device performance and reliability. The Plain Metallic Conductive Fabric Tape EMI Shielding for LCD Display and Precision Electronic Assembly represents a cutting-edge solution designed to address these critical concerns. This specialized shielding material combines advanced conductive properties with practical application versatility, making it an essential component for manufacturers seeking to enhance their electronic products' electromagnetic compatibility.

Modern electronic devices demand sophisticated protection against EMI disruption, particularly in sensitive applications involving display technologies and precision circuitry. This conductive fabric tape delivers superior electromagnetic shielding effectiveness while maintaining the flexibility and ease of installation that modern manufacturing processes require. Its unique composition and design characteristics make it particularly suitable for protecting LCD displays and other precision electronic assemblies from unwanted electromagnetic interference.

Product Overview

The Plain Metallic Conductive Fabric Tape EMI Shielding for LCD Display and Precision Electronic Assembly features a sophisticated multi-layer construction that combines metallic conductivity with fabric flexibility. This innovative design approach ensures optimal electromagnetic shielding performance while maintaining the mechanical properties necessary for reliable long-term operation in demanding electronic environments.

Constructed with high-quality conductive materials, this EMI shielding tape provides exceptional attenuation across a broad frequency spectrum. The metallic components are carefully integrated with textile substrates to create a product that offers both electrical conductivity and mechanical durability. This unique combination makes it particularly effective for applications requiring both electromagnetic protection and physical resilience.

The tape's plain design philosophy emphasizes functional excellence over decorative elements, ensuring that resources are focused on delivering superior shielding performance. This approach results in a product that provides consistent electromagnetic protection while maintaining cost-effectiveness for high-volume manufacturing applications. The fabric construction allows for excellent conformability to irregular surfaces and complex geometries commonly found in modern electronic assemblies.

Features & Benefits

Advanced Electromagnetic Shielding Properties

The conductive fabric tape delivers exceptional electromagnetic interference suppression across both electric and magnetic field applications. Its metallic composition ensures reliable conductivity while the fabric substrate provides mechanical stability and ease of handling. This combination results in consistent shielding effectiveness that maintains performance integrity throughout the product lifecycle.

The tape's design optimizes both near-field and far-field electromagnetic shielding capabilities, making it suitable for diverse electronic environments. Its broad-spectrum effectiveness ensures comprehensive protection against various interference sources, from low-frequency magnetic fields to high-frequency electromagnetic radiation. This versatility makes it an ideal choice for complex electronic systems requiring multi-faceted EMI protection.

Superior Conformability and Application Versatility

The fabric substrate provides excellent flexibility and conformability, allowing the tape to adapt to curved surfaces, corners, and irregular geometries commonly encountered in electronic assemblies. This adaptability ensures complete coverage and eliminates gaps that could compromise shielding effectiveness. The material's flexibility also facilitates installation in tight spaces and complex routing situations.

Installation simplicity represents another key advantage, as the tape can be easily applied using standard manufacturing processes without requiring specialized equipment or extensive training. This ease of application reduces manufacturing complexity while ensuring consistent results across production runs. The material's handling characteristics support both manual and automated installation methods, providing flexibility for various production environments.

Applications & Use Cases

LCD display applications represent a primary use case for this Plain Metallic Conductive Fabric Tape EMI Shielding for LCD Display and Precision Electronic Assembly. Modern display technologies are particularly susceptible to electromagnetic interference, which can manifest as visual artifacts, color distortions, or performance degradation. The conductive fabric tape provides essential protection for display modules, ensuring optimal visual performance and eliminating interference-related issues that could compromise user experience.

Precision electronic assemblies across numerous industries benefit from this specialized shielding solution. Medical devices, aerospace systems, automotive electronics, and telecommunications equipment all require reliable EMI protection to maintain operational integrity. The tape's versatility makes it suitable for protecting sensitive analog circuits, digital processing units, signal conditioning modules, and other critical electronic components that demand stable electromagnetic environments.

Consumer electronics applications increasingly rely on this type of EMI shielding to ensure regulatory compliance and optimal performance. Mobile devices, tablets, laptops, and gaming systems all incorporate sensitive electronic components that require protection from both internal and external electromagnetic interference. The conductive fabric tape provides an effective solution for manufacturers seeking to enhance product reliability while maintaining compact form factors.

Industrial automation and control systems represent another significant application area where electromagnetic compatibility is crucial. Process control equipment, sensors, actuators, and communication modules all benefit from reliable EMI shielding to ensure accurate operation in electrically noisy industrial environments. The tape's durability and consistent performance characteristics make it particularly suitable for these demanding applications.

Quality Control & Compliance

Manufacturing excellence drives every aspect of production for this conductive fabric tape, ensuring consistent quality and reliable performance across all product batches. Comprehensive quality control protocols monitor material composition, conductivity characteristics, adhesive performance, and mechanical properties throughout the manufacturing process. These rigorous standards ensure that each roll of tape meets the exacting requirements necessary for critical electronic applications.

International compliance standards guide product development and manufacturing processes, ensuring compatibility with global electromagnetic compatibility requirements. The tape is designed to support customer compliance efforts across various regulatory frameworks, including those governing medical devices, automotive systems, and telecommunications equipment. This compliance-focused approach helps manufacturers achieve certification requirements more efficiently.

Environmental considerations play an important role in material selection and manufacturing processes. The product incorporates environmentally responsible materials and manufacturing practices while maintaining performance excellence. This commitment to environmental stewardship helps customers meet their own sustainability objectives without compromising on technical performance or reliability.

Continuous improvement initiatives drive ongoing enhancements to both product performance and manufacturing processes. Regular evaluation of customer feedback, industry trends, and technological advances ensures that the product continues to evolve to meet changing market needs. This commitment to innovation helps maintain the product's position as a leading EMI shielding solution.

Customization & Branding Options

Flexible customization capabilities enable customers to tailor the Plain Metallic Conductive Fabric Tape EMI Shielding for LCD Display and Precision Electronic Assembly to meet specific application requirements. Width variations, adhesive selections, and backing material options can be modified to optimize performance for particular use cases. This customization approach ensures that customers receive a product that precisely matches their technical and operational needs.

Advanced engineering support helps customers optimize their EMI shielding strategies through collaborative development efforts. Technical specialists work closely with customer engineering teams to identify the most effective shielding approaches for specific applications. This collaborative approach often results in innovative solutions that exceed standard product capabilities while maintaining cost-effectiveness.

Private labeling and branding services enable distributors and OEM customers to incorporate their own brand identity into the product packaging and documentation. Professional packaging design and marketing material development support customer brand positioning while maintaining product quality and performance standards. These services help customers strengthen their market presence while offering proven EMI shielding solutions.

Technical documentation customization ensures that customers receive application-specific guidance and installation instructions. Custom technical data sheets, application guides, and installation procedures can be developed to support specific customer requirements. This documentation support enhances customer success while reducing technical support requirements and improving overall satisfaction.

Packaging & Logistics Support

Comprehensive packaging solutions protect product integrity throughout the supply chain while optimizing logistics efficiency. Specialized packaging materials and methods ensure that the conductive fabric tape maintains its performance characteristics during storage and transportation. Climate-controlled storage recommendations and packaging specifications help customers maintain product quality from receipt through application.

Global distribution capabilities enable efficient delivery to customers worldwide through established logistics partnerships and distribution networks. Strategic warehouse locations and inventory management systems ensure reliable product availability while minimizing delivery times. This global reach supports international customers and facilitates expansion into new markets.

Inventory management support helps customers optimize their supply chain efficiency through flexible ordering options and inventory planning assistance. Just-in-time delivery programs and scheduled shipment options enable customers to maintain optimal inventory levels while ensuring uninterrupted production schedules. These services reduce carrying costs while maintaining production flexibility.

Sustainable packaging initiatives incorporate environmentally responsible materials and practices while maintaining product protection standards. Recyclable packaging materials, optimized package sizes, and reduced material usage contribute to overall environmental sustainability. These initiatives help customers meet their own environmental objectives while supporting responsible supply chain practices.

Why Choose Us

Our organization brings decades of experience in electromagnetic interference solutions and conductive materials technology to every customer relationship. This extensive background in EMI shielding applications across diverse industries provides the foundation for developing innovative products that meet evolving market needs. Our international presence and collaborative relationships with customers worldwide demonstrate our commitment to supporting global electronics manufacturing requirements.

As a recognized metal packaging manufacturer and custom tin box supplier, our expertise extends beyond individual products to comprehensive packaging solutions that protect and enhance electronic components. Our experience as an OEM tin packaging solutions provider and established metal packaging supplier enables us to understand the complete product lifecycle and develop solutions that optimize both performance and manufacturability.

Technical innovation drives our product development efforts, ensuring that our EMI shielding solutions remain at the forefront of industry advancement. Continuous research and development investments enable us to anticipate market trends and develop products that meet tomorrow's challenges today. This forward-thinking approach helps customers maintain their competitive advantage while reducing technical risk.

Customer success represents our primary objective, guiding every aspect of our operations from initial product development through ongoing technical support. Our collaborative approach ensures that customers receive not just products, but comprehensive solutions that enhance their overall success. This commitment to customer excellence has established long-term partnerships with industry leaders worldwide and continues to drive our growth and innovation efforts.

Conclusion

The Plain Metallic Conductive Fabric Tape EMI Shielding for LCD Display and Precision Electronic Assembly represents a sophisticated solution to the growing challenges of electromagnetic interference in modern electronics. Its unique combination of metallic conductivity, fabric flexibility, and application versatility makes it an essential component for manufacturers seeking to enhance their products' electromagnetic compatibility while maintaining operational efficiency. Through comprehensive quality control, customization capabilities, and global logistics support, this EMI shielding solution delivers the performance, reliability, and service excellence that today's electronics industry demands. The product's proven effectiveness across diverse applications, from LCD displays to precision electronic assemblies, demonstrates its value as a critical component in achieving electromagnetic compatibility objectives while supporting overall product success.

Professional EMI Shielding Tapes - Total Solution for RFI/ESD Protection

Excellent Shielding Performance |

Offers high shielding effectiveness over a wide frequency range, ideal for EMI, RFI, and ESD full protection. |

||||||

High Conductivity & Low Resistance |

Made from superior materials like nickel/copper coated fabric or pure copper foil, ensuring good electrical conductivity and reliable grounding. |

||||||

Flexible & Conformable |

Ultra-thin, flexible, and lightweight design allows for easy application on curved surfaces and tight spaces, such as internal circuit boards and flexible circuits. |

||||||

Customizable Solutions |

Available in custom sizes, shapes, and die-cuts (OEM/ODM supported). RoHS and REACH compliant to meet global environmental standards. |

||||||

Consumer Electronics |

Smartphones, laptops, gaming consoles, LCD displays, and 5G wireless chargers for internal circuit board shielding and high-speed HDMI signal protection. |

||||||

Automotive & Transportation |

Automotive electronics, autonomous vehicles LiDAR/Radar systems, and EV wireless chargers as part of robust EMC solutions. |

||||||

Telecom & Networking |

Networking equipment, 5G infrastructure, and cabinet shielding to ensure signal integrity and prevent interference. |

||||||

Industrial & Medical

|

Industrial control systems, power supplies, and sensitive medical electronic devices requiring reliable performance in demanding conditions. |

||||||

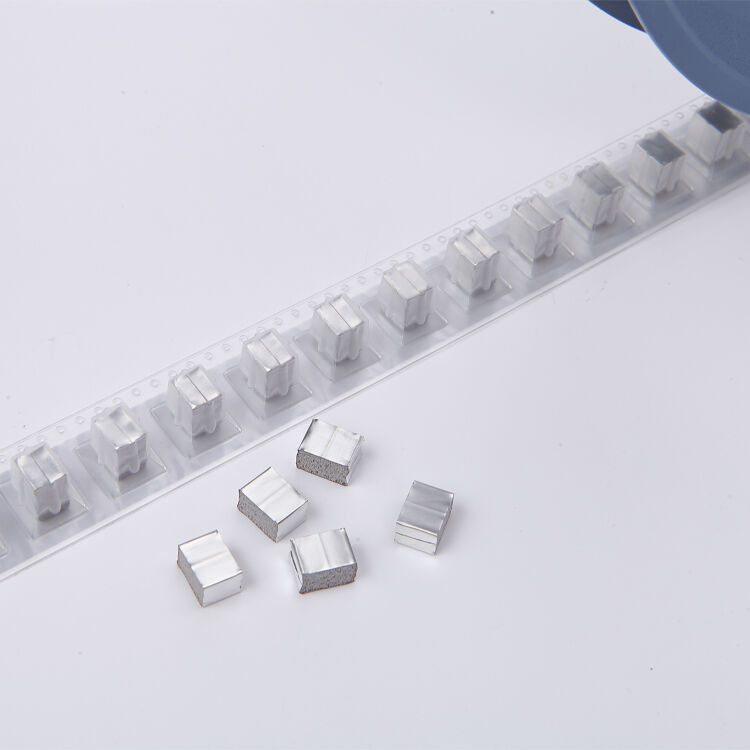

Available Types

Company Profile

We cater primarily to the consumer electronics, communication networks, and emerging energy vehicle sectors. To back ourcommitment to quality and innovation, we have established a national production base across four strategic locations:

1. A 1,000-square-meter new material formula R&D center in Shenzhen.

2. A 2,000-square-meter innovative grounding wrapping production plant in Dongguan.

3. A 10,000-square-meter conductive shielding tape coating plant in Hunan.

4. A 1,000-square-meter magnetron sputtering continuous gold/tin plating plant in Shandong.

As the only vertically integrated integrator in China offering electroplating, coating, and processing capabilities, we strive to become a leading innovator and provider of core values within the materials industry chain. Our ultimate goal is to be a long-term trusted solution provider and partner for our customers in addressing their challenges.

Invention Patent

System certification

FAQ

We are based in Guangdong, China, start from 2011,sell to South Asia(10.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Shielding tape,Adhesive tapes,Waterproof and breathable membrane,Customized production,Raw material die-cutting

4. why should you buy from us not from other suppliers?

Shenzhen Johan Material Tech Co., Ltd. was established in 2011, and is an innovative national high-tech enterprise providing

innovative EMC (electromagnetic compatibility) grounding elastomers and customized tape solutions for the electronics indus

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency: USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken: English,Chinese