Introduction

In today's increasingly complex electronic environment, electromagnetic interference poses significant challenges across military, aerospace, and critical infrastructure applications. The demand for reliable EMI mitigation solutions has never been greater, particularly in defense scenarios where signal integrity and operational security are paramount. Advanced copper foil tapes specifically engineered for electromagnetic shielding represent a crucial component in protecting sensitive equipment from unwanted interference while maintaining optimal performance standards.

Modern defense systems require sophisticated protection mechanisms that can withstand harsh environmental conditions while delivering consistent shielding effectiveness. High Performance EMI Absorbing Copper Foil Tape for Defense and Shielding emerges as a specialized solution designed to meet these stringent requirements, offering superior electromagnetic compatibility across diverse operational contexts.

Product Overview

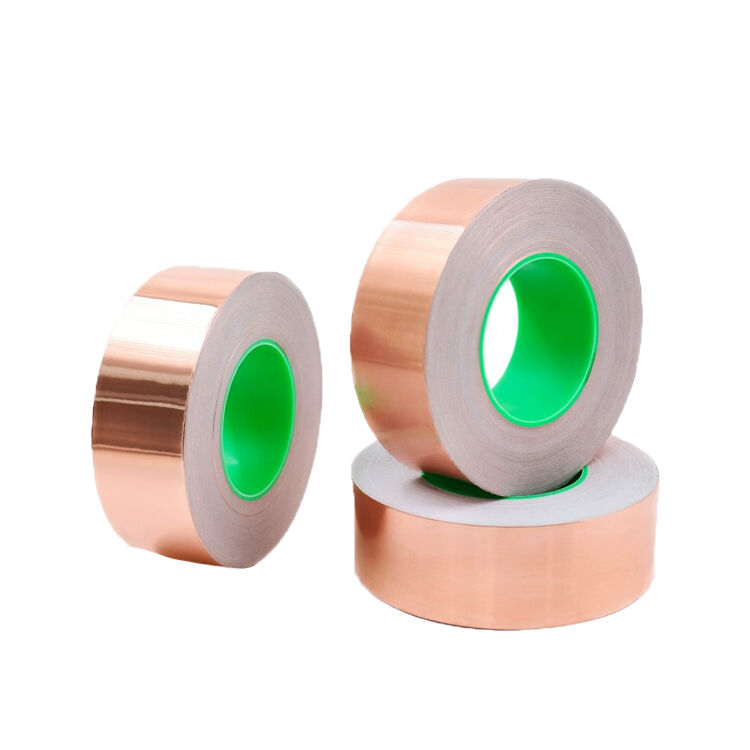

This advanced electromagnetic interference shielding solution combines premium copper construction with specialized absorbing materials to create a versatile defense-grade tape system. The product incorporates multiple layers of carefully engineered materials that work synergistically to provide both reflection and absorption of electromagnetic energy across broad frequency ranges.

The copper foil foundation delivers excellent electrical conductivity essential for effective EMI shielding, while the integrated absorbing components help minimize reflection and standing wave formation. This dual-action approach ensures comprehensive protection against electromagnetic interference in critical applications where standard shielding materials may prove inadequate.

Engineered specifically for demanding defense applications, this shielding tape maintains its protective properties under extreme temperature variations, humidity exposure, and mechanical stress. The adhesive system provides reliable bonding to various substrate materials commonly found in military electronics, communication systems, and sensitive instrumentation.

Features & Benefits

Advanced Material Engineering

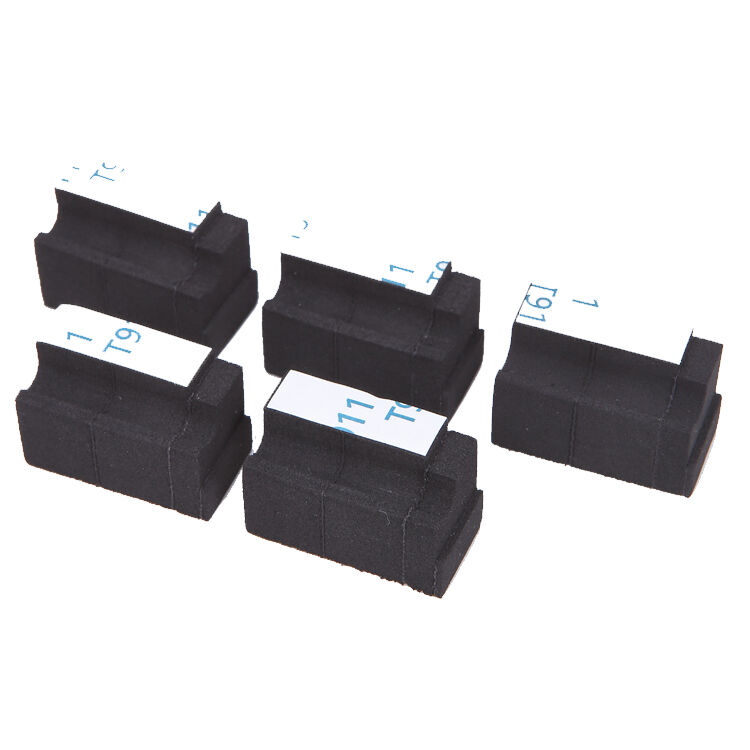

The sophisticated material composition delivers exceptional electromagnetic shielding effectiveness while maintaining flexibility and ease of application. The copper foil substrate provides low resistance pathways for electromagnetic current flow, creating effective Faraday cage protection around sensitive components. The integrated absorbing elements work to minimize unwanted reflections that could create interference patterns or compromise nearby equipment operation.

Superior adhesive formulation ensures long-term bonding performance across temperature extremes and environmental exposure conditions typical in defense applications. The adhesive maintains its integrity without degrading the underlying shielding properties, providing reliable protection throughout extended service intervals.

Operational Reliability

Consistent performance across wide frequency spectrums makes this High Performance EMI Absorbing Copper Foil Tape for Defense and Shielding suitable for protecting against various interference sources simultaneously. The material maintains its shielding effectiveness regardless of environmental conditions, ensuring critical systems remain protected during extended deployments.

The tape construction allows for easy installation in confined spaces and complex geometries where rigid shielding solutions would prove impractical. This flexibility enables comprehensive protection of irregularly shaped components while maintaining the electrical continuity essential for effective EMI mitigation.

Durability and Longevity

Robust construction withstands mechanical stress, vibration, and environmental exposure without compromising shielding performance. The materials resist corrosion and oxidation that could degrade electrical properties over time, ensuring consistent protection throughout the product lifecycle.

Chemical resistance protects against exposure to cleaning solvents, fuels, and other substances commonly encountered in military environments. This resistance helps maintain both the physical integrity and electromagnetic shielding properties under real-world operating conditions.

Applications & Use Cases

Military communication systems represent a primary application area where High Performance EMI Absorbing Copper Foil Tape for Defense and Shielding provides critical protection. Radio frequency equipment, satellite communication terminals, and secure communication devices benefit from the comprehensive electromagnetic protection that prevents both interference reception and signal leakage that could compromise operational security.

Aerospace applications demand exceptional reliability and performance consistency across extreme environmental conditions. The tape provides effective shielding for avionics systems, navigation equipment, and flight control electronics where electromagnetic interference could compromise safety or mission success. The material's ability to maintain its properties at altitude and under temperature variations makes it ideal for aircraft and spacecraft applications.

Naval and maritime systems face unique challenges from saltwater environments and electromagnetic interference from various onboard systems. The corrosion-resistant properties and reliable adhesion make this shielding solution particularly valuable for protecting sensitive electronics aboard military vessels and submarines.

Ground-based radar systems and electronic warfare equipment require sophisticated EMI protection to maintain operational effectiveness. The tape provides localized shielding for critical components while allowing system modifications and maintenance access. This flexibility proves essential in rapidly evolving electronic warfare scenarios where equipment configurations may require frequent updates.

Cybersecurity applications increasingly recognize the importance of preventing electromagnetic emanations that could reveal sensitive information. The absorbing properties help minimize unintentional electromagnetic signatures from computing and communication equipment, supporting TEMPEST and other information security requirements.

Quality Control & Compliance

Stringent manufacturing processes ensure consistent product quality and performance characteristics across production batches. Each roll undergoes comprehensive testing to verify electromagnetic shielding effectiveness, adhesive performance, and material integrity before shipment. Advanced quality control systems monitor critical parameters throughout the manufacturing process to maintain the exacting standards required for defense applications.

International quality standards guide the production and testing procedures, ensuring compatibility with global defense procurement requirements. The manufacturing facility maintains certifications relevant to defense industry suppliers, demonstrating commitment to quality and security standards expected by military customers worldwide.

Environmental compliance ensures the product meets current regulations regarding hazardous materials and environmental impact. The manufacturing process incorporates sustainable practices where possible while maintaining the performance standards essential for critical defense applications.

Comprehensive documentation accompanies each shipment, providing traceability information and performance data necessary for defense applications. This documentation supports customer quality assurance programs and regulatory compliance requirements common in military procurement processes.

Customization & Branding Options

Tailored solutions accommodate specific application requirements that may differ from standard product configurations. Engineering teams work closely with customers to develop modified formulations or constructions that address unique electromagnetic interference challenges or environmental conditions. These customization capabilities extend to adhesive selection, thickness optimization, and specialized surface treatments.

Width and length specifications can be adjusted to match specific installation requirements, reducing waste and simplifying application procedures. Custom packaging options support different storage and handling requirements while maintaining product integrity during transportation and storage.

Private labeling services enable customers to incorporate their branding and specification information directly on product packaging and documentation. This service supports original equipment manufacturers and system integrators who require consistent branding across their product lines.

Performance modifications can address specific frequency ranges or environmental conditions that require enhanced protection characteristics. Engineering support assists customers in identifying optimal configurations for their particular applications, ensuring maximum effectiveness while maintaining cost efficiency.

Packaging & Logistics Support

Professional packaging systems protect product integrity during international shipping and long-term storage. Moisture barrier materials and controlled atmosphere packaging prevent degradation of adhesive properties and ensure the tape maintains its performance characteristics until application. Packaging configurations accommodate various order quantities while optimizing shipping efficiency and storage requirements.

Global distribution capabilities support customers worldwide through established logistics networks and regional stocking programs. Strategic inventory placement reduces delivery timeframes while ensuring product availability for urgent defense requirements. Temperature-controlled shipping options protect product quality during transportation through various climate zones.

Documentation packages include comprehensive technical data sheets, application guidelines, and safety information in multiple languages to support international customers. Digital documentation options provide immediate access to product information and technical support resources.

Flexible shipping options accommodate both routine procurement cycles and emergency requirements common in defense applications. Express shipping capabilities ensure critical projects receive priority handling when operational timelines demand immediate product availability.

Why Choose Us

With over two decades of experience serving the global defense and aerospace industries, our company has established itself as a trusted metal packaging manufacturer and supplier of specialized electromagnetic shielding solutions. Our comprehensive understanding of both electromagnetic theory and practical application challenges enables us to deliver products that consistently exceed customer expectations in demanding environments.

International market presence across multiple continents ensures responsive customer support and technical assistance regardless of project location. Our global network includes regional technical specialists who understand local regulations and application requirements, providing valuable support throughout the procurement and implementation process.

As a recognized custom tin box supplier and OEM tin packaging solutions provider, our diversified manufacturing capabilities support various packaging and protection requirements beyond electromagnetic shielding. This breadth of expertise enables comprehensive solutions that address multiple project requirements through a single supplier relationship.

Our metal packaging supplier credentials include partnerships with leading defense contractors and system integrators who demand the highest quality standards and most reliable performance. These relationships have been built through consistent delivery of superior products and exceptional technical support across numerous successful projects.

Continuous research and development programs ensure our High Performance EMI Absorbing Copper Foil Tape for Defense and Shielding incorporates the latest advances in materials science and electromagnetic engineering. Our technical teams actively monitor emerging threats and evolving requirements to maintain product relevance in rapidly changing defense environments.

Conclusion

High Performance EMI Absorbing Copper Foil Tape for Defense and Shielding represents a sophisticated solution for protecting critical electronics against electromagnetic interference in demanding operational environments. The combination of advanced materials engineering, proven reliability, and comprehensive performance characteristics makes this product an essential component in modern defense and aerospace applications. Its versatility across diverse application scenarios, coupled with customization capabilities and global logistics support, ensures customers receive optimal protection solutions tailored to their specific requirements. The product's adherence to stringent quality standards and environmental compliance requirements further reinforces its suitability for critical applications where failure is not an option.

Professional EMI Shielding Tapes - Total Solution for RFI/ESD Protection

Excellent Shielding Performance |

Offers high shielding effectiveness over a wide frequency range, ideal for EMI, RFI, and ESD full protection. |

||||||

High Conductivity & Low Resistance |

Made from superior materials like nickel/copper coated fabric or pure copper foil, ensuring good electrical conductivity and reliable grounding. |

||||||

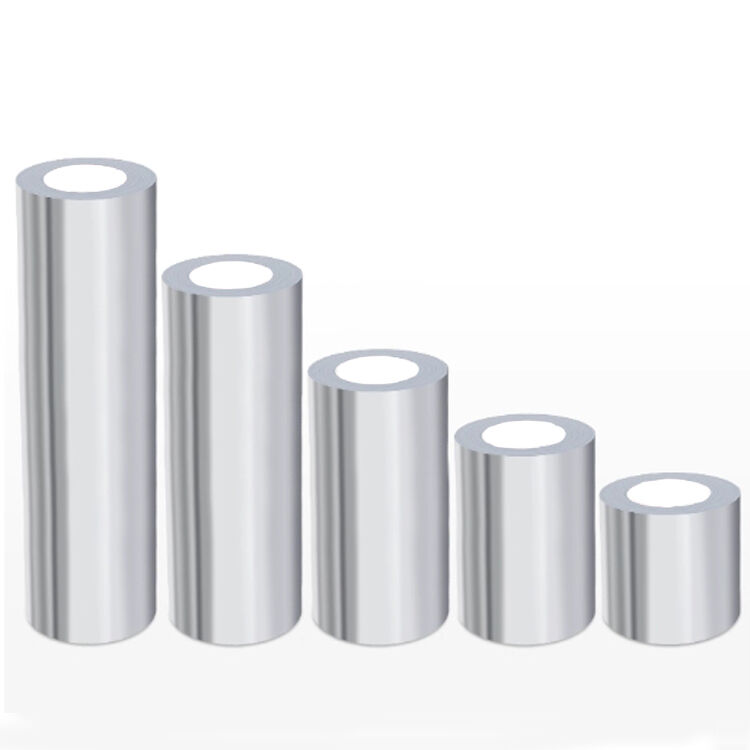

Flexible & Conformable |

Ultra-thin, flexible, and lightweight design allows for easy application on curved surfaces and tight spaces, such as internal circuit boards and flexible circuits. |

||||||

Customizable Solutions |

Available in custom sizes, shapes, and die-cuts (OEM/ODM supported). RoHS and REACH compliant to meet global environmental standards. |

||||||

Consumer Electronics |

Smartphones, laptops, gaming consoles, LCD displays, and 5G wireless chargers for internal circuit board shielding and high-speed HDMI signal protection. |

||||||

Automotive & Transportation |

Automotive electronics, autonomous vehicles LiDAR/Radar systems, and EV wireless chargers as part of robust EMC solutions. |

||||||

Telecom & Networking |

Networking equipment, 5G infrastructure, and cabinet shielding to ensure signal integrity and prevent interference. |

||||||

Industrial & Medical

|

Industrial control systems, power supplies, and sensitive medical electronic devices requiring reliable performance in demanding conditions. |

||||||

Available Types

Company Profile

We cater primarily to the consumer electronics, communication networks, and emerging energy vehicle sectors. To back ourcommitment to quality and innovation, we have established a national production base across four strategic locations:

1. A 1,000-square-meter new material formula R&D center in Shenzhen.

2. A 2,000-square-meter innovative grounding wrapping production plant in Dongguan.

3. A 10,000-square-meter conductive shielding tape coating plant in Hunan.

4. A 1,000-square-meter magnetron sputtering continuous gold/tin plating plant in Shandong.

As the only vertically integrated integrator in China offering electroplating, coating, and processing capabilities, we strive to become a leading innovator and provider of core values within the materials industry chain. Our ultimate goal is to be a long-term trusted solution provider and partner for our customers in addressing their challenges.

Invention Patent

System certification

FAQ

We are based in Guangdong, China, start from 2011,sell to South Asia(10.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Shielding tape,Adhesive tapes,Waterproof and breathable membrane,Customized production,Raw material die-cutting

4. why should you buy from us not from other suppliers?

Shenzhen Johan Material Tech Co., Ltd. was established in 2011, and is an innovative national high-tech enterprise providing

innovative EMC (electromagnetic compatibility) grounding elastomers and customized tape solutions for the electronics indus

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency: USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken: English,Chinese