Introduction

In today's demanding industrial landscape, engineers and manufacturers require advanced sealing solutions that deliver exceptional performance under extreme conditions. The Zero Permanent Compression Set Poron Foam Sheet High Rebond for Electronics Automotive Gaskets represents a breakthrough in cellular urethane technology, engineered specifically for applications where traditional gasket materials fail to meet stringent performance requirements. This innovative foam material combines superior resilience with outstanding compression recovery characteristics, making it the preferred choice for critical sealing applications across electronics, automotive, and industrial sectors.

Modern manufacturing environments demand materials that can withstand repeated compression cycles while maintaining their original dimensions and sealing properties. Our advanced Poron foam technology addresses these challenges by delivering consistent performance throughout extended operational lifecycles, ensuring reliable protection against environmental contamination, electromagnetic interference, and mechanical stress in sophisticated assemblies.

Product Overview

The Zero Permanent Compression Set Poron Foam Sheet High Rebond for Electronics Automotive Gaskets is manufactured using proprietary microcellular urethane chemistry that creates an exceptionally uniform cell structure. This advanced material architecture enables superior compression recovery while maintaining excellent conformability to irregular surfaces and complex geometries. The foam's unique molecular composition provides outstanding resistance to environmental stressors including temperature fluctuations, humidity variations, and chemical exposure commonly encountered in demanding industrial applications.

Our high-rebond formulation incorporates specialized additives that enhance the material's elastic memory, allowing it to return to its original thickness even after prolonged compression loading. This characteristic is particularly valuable in applications where gaskets experience cyclic compression forces or where assembly tolerances vary due to thermal expansion and manufacturing variations. The material's consistent density profile ensures predictable compression force deflection characteristics across the entire sheet surface.

Features & Benefits

Advanced Compression Recovery Technology

The Zero Permanent Compression Set Poron Foam Sheet High Rebond for Electronics Automotive Gaskets features revolutionary compression set resistance that maintains sealing integrity throughout extended service intervals. Unlike conventional foam materials that gradually lose thickness under constant compression, this advanced formulation demonstrates exceptional elastic recovery even after prolonged loading cycles. This characteristic translates to reduced maintenance requirements and enhanced long-term reliability in critical sealing applications.

Superior Conformability and Surface Contact

The material's microcellular structure enables excellent conformability to surface irregularities while maintaining consistent compression force distribution. This property ensures optimal sealing performance across varying surface finishes and geometric tolerances commonly encountered in precision assemblies. The foam's ability to adapt to surface variations while maintaining structural integrity makes it ideal for applications requiring reliable environmental protection.

Enhanced Chemical and Environmental Resistance

Our specialized urethane chemistry provides excellent resistance to oils, fuels, cleaning solvents, and atmospheric contaminants typically encountered in automotive and electronic environments. The material maintains its physical properties and sealing performance when exposed to temperature cycling, humidity variations, and UV radiation, ensuring consistent protection throughout demanding operational conditions.

Applications & Use Cases

The Zero Permanent Compression Set Poron Foam Sheet High Rebond for Electronics Automotive Gaskets serves critical functions across diverse industrial sectors where reliable sealing performance is essential. In automotive applications, this material provides exceptional protection for electronic control modules, sensor housings, and battery compartments where resistance to vibration, temperature extremes, and chemical exposure is paramount. The foam's ability to maintain consistent sealing forces ensures optimal performance of sensitive electronic components while preventing moisture ingress and contamination.

Electronic device manufacturers utilize this advanced material for EMI shielding gaskets, display assemblies, and connector sealing applications where precise compression control and long-term stability are required. The material's excellent recovery characteristics make it particularly suitable for portable devices that experience frequent opening and closing cycles, maintaining effective environmental sealing throughout the product lifecycle.

Industrial equipment applications benefit from the material's resistance to hydraulic fluids, lubricants, and process chemicals while providing reliable sealing performance in pumps, filtration systems, and control panel assemblies. The foam's ability to accommodate thermal expansion and manufacturing tolerances ensures consistent sealing performance across varying operational conditions and assembly configurations.

Quality Control & Compliance

Our manufacturing processes adhere to stringent quality management systems that ensure consistent material properties and performance characteristics across all production batches. Advanced testing protocols validate compression set resistance, tensile properties, and environmental durability through accelerated aging studies and real-world simulation testing. These comprehensive evaluation procedures guarantee that each foam sheet meets demanding specifications for critical sealing applications.

The Zero Permanent Compression Set Poron Foam Sheet High Rebond for Electronics Automotive Gaskets complies with international material standards and automotive specifications, providing manufacturers with confidence in regulatory compliance and performance reliability. Our quality assurance programs include statistical process control monitoring and traceability systems that maintain detailed documentation throughout the manufacturing and distribution process.

Environmental compliance represents a core commitment in our manufacturing operations, with materials formulated to meet current and emerging regulations regarding volatile organic compounds and hazardous substances. This proactive approach ensures long-term supply chain stability while supporting our customers' sustainability objectives and regulatory requirements.

Customization & Branding Options

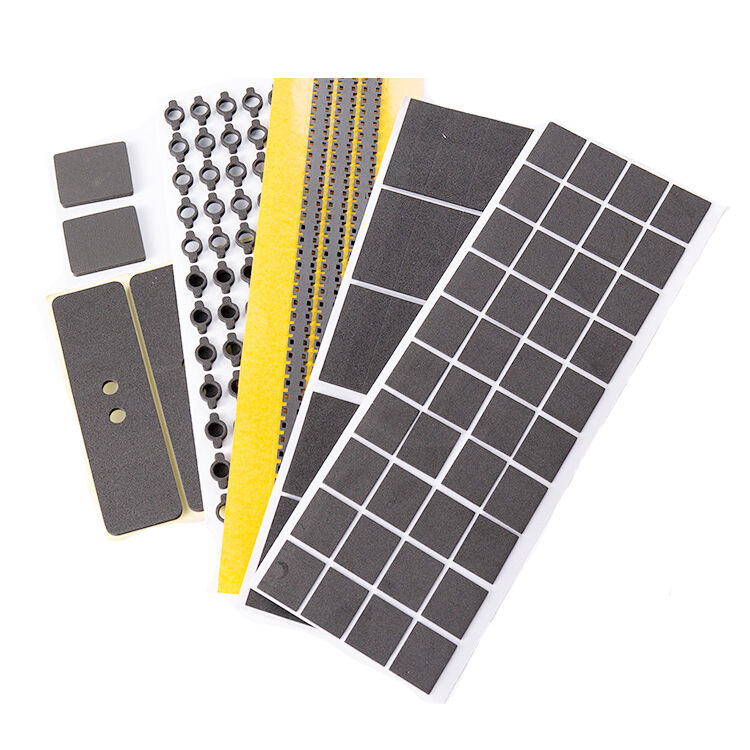

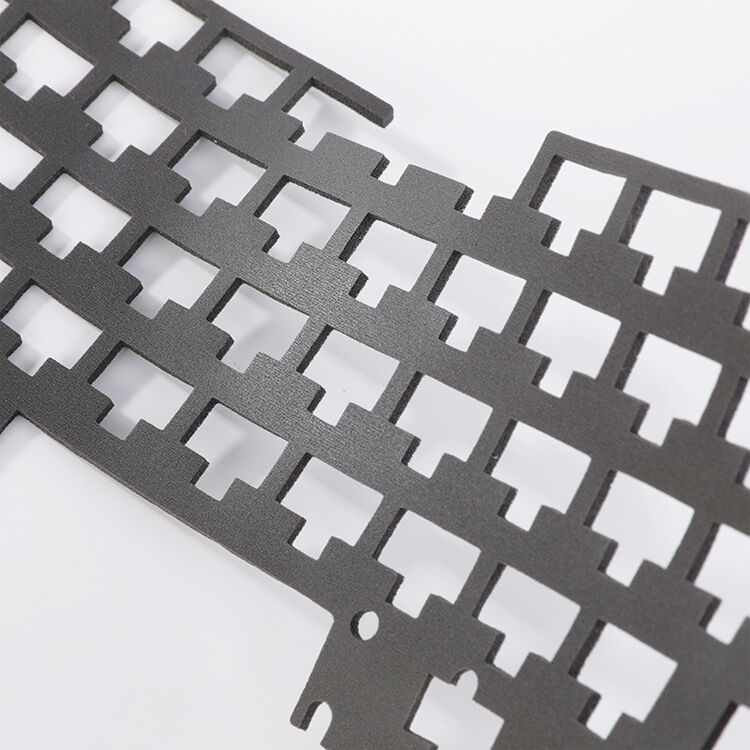

Understanding the diverse requirements of modern manufacturing applications, we offer comprehensive customization capabilities for the Zero Permanent Compression Set Poron Foam Sheet High Rebond for Electronics Automotive Gaskets. Our engineering team collaborates with customers to develop tailored solutions that address specific application requirements including custom thicknesses, adhesive backing options, and precision die-cutting services that optimize assembly processes and reduce manufacturing costs.

Advanced conversion capabilities include kiss-cutting, through-cutting, and lamination services that enable direct integration into automated assembly processes. Custom packaging solutions support efficient inventory management and just-in-time manufacturing requirements while maintaining material integrity and cleanliness standards essential for sensitive applications.

Technical support services include application engineering assistance, material selection guidance, and prototype development support that accelerates product development cycles and ensures optimal material performance in specific applications. Our experienced engineering team provides comprehensive documentation and testing support to facilitate material qualification processes and regulatory approvals.

Packaging & Logistics Support

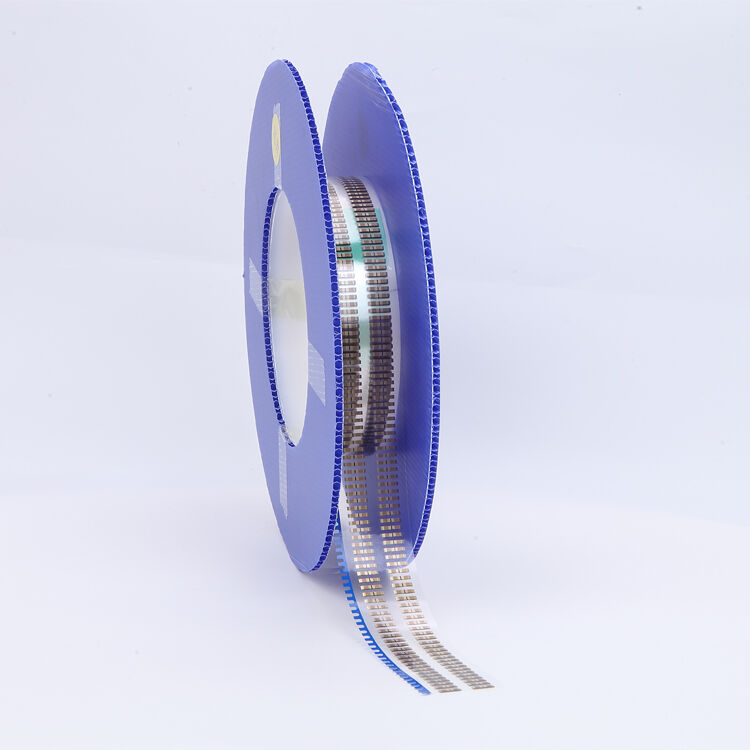

Our comprehensive packaging solutions protect the Zero Permanent Compression Set Poron Foam Sheet High Rebond for Electronics Automotive Gaskets throughout global distribution while supporting efficient inventory management and manufacturing processes. Protective packaging systems prevent compression set during storage and transportation, ensuring that materials retain their specified properties when received by customers.

Flexible shipping configurations accommodate varying order quantities and delivery requirements while maintaining cost-effective logistics solutions for international customers. Our distribution network provides reliable supply chain support with strategic inventory positioning that minimizes lead times and supports just-in-time manufacturing requirements.

Specialized packaging options include moisture barrier protection, static-dissipative materials, and cleanroom-compatible containers that meet the stringent requirements of electronics manufacturing and automotive assembly environments. These advanced packaging solutions ensure material integrity and performance consistency throughout the supply chain.

Why Choose Us

With decades of experience serving international markets, our company has established a reputation as a trusted custom tin box supplier and advanced materials manufacturer, delivering innovative solutions that meet the evolving needs of global industries. Our expertise spans multiple sectors including electronics, automotive, and industrial applications where demanding performance requirements drive continuous innovation and material advancement.

Our commitment to excellence extends beyond material manufacturing to encompass comprehensive technical support, application engineering, and customer service that ensures successful implementation of the Zero Permanent Compression Set Poron Foam Sheet High Rebond for Electronics Automotive Gaskets in critical applications. As a recognized metal packaging supplier and materials specialist, we understand the importance of reliable supply chain partnerships and consistent quality delivery.

Global manufacturing capabilities and distribution networks enable responsive service to customers worldwide while maintaining the high-quality standards essential for critical sealing applications. Our investment in advanced manufacturing technology and quality systems ensures consistent material properties and reliable performance that supports our customers' success in competitive markets.

Conclusion

The Zero Permanent Compression Set Poron Foam Sheet High Rebond for Electronics Automotive Gaskets represents the pinnacle of advanced sealing technology, combining exceptional compression recovery with outstanding environmental resistance and long-term stability. This innovative material addresses the critical challenges facing modern manufacturers who require reliable sealing solutions for demanding applications across electronics, automotive, and industrial sectors. Through its superior performance characteristics, comprehensive customization options, and robust quality assurance programs, this advanced foam material enables manufacturers to achieve optimal sealing performance while reducing maintenance requirements and enhancing product reliability throughout extended operational lifecycles.

Polyurethane Foam: The Versatile High-Performance Sealing and Cushioning Material

Color |

Density |

Hardness |

Temperature Range |

Certifications |

Black

|

100~480 kg/m³

|

3~50 Shore 00/Shore A |

-20°C to +90°C

|

RoHS, REACH, UL94 HF-1 Flame Retardant Standards |

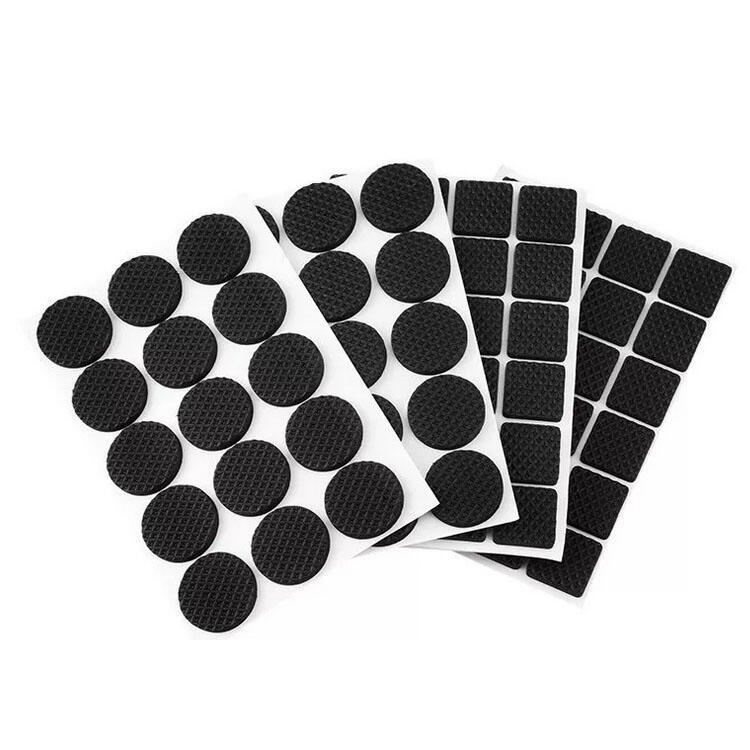

* Electronics & Appliances: Sealing gaskets for control panels, shock-absorbing pads for sensitive components, battery padding.

* Automotive Industry: Sealing for doors, windows, and lights; sound insulation and vibration damping in interiors.

* Medical Equipment: Cushioning for medical devices, sealing for enclosures, providing comfort and protection.

Invention Patent

System certification

Company Profile

We cater primarily to the consumer electronics, communication networks, and emerging energy vehicle sectors. To back ourcommitment to quality and innovation, we have established a national production base across four strategic locations:

1. A 1,000-square-meter new material formula R&D center in Shenzhen.

2. A 2,000-square-meter innovative grounding wrapping production plant in Dongguan.

3. A 10,000-square-meter conductive shielding tape coating plant in Hunan.

4. A 1,000-square-meter magnetron sputtering continuous gold/tin plating plant in Shandong.

As the only vertically integrated integrator in China offering electroplating, coating, and processing capabilities, we strive to become a leading innovator and provider of core values within the materials industry chain. Our ultimate goal is to be a long-term trusted solution provider and partner for our customers in addressing their challenges.

FAQ

We are based in Guangdong, China, start from 2011,sell to South Asia(10.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Shielding tape,Adhesive tapes,Waterproof and breathable membrane,Customized production,Raw material die-cutting

4. why should you buy from us not from other suppliers?

Shenzhen Johan Material Tech Co., Ltd. was established in 2011, and is an innovative national high-tech enterprise providing

innovative EMC (electromagnetic compatibility) grounding elastomers and customized tape solutions for the electronics indus

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency: USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken: English,Chinese