Introduction

In today's demanding industrial landscape, engineers and manufacturers require advanced materials that can effectively manage vibration, reduce noise pollution, and withstand high-impact conditions. The Professional Grade Rogers Foam Sheet High Impact Resistance for Vibration Noise Damping Engineering represents a breakthrough solution designed to meet these critical performance requirements across diverse applications. This premium foam material combines superior shock absorption capabilities with exceptional durability, making it an indispensable component for modern engineering projects that prioritize both performance and reliability.

Developed using cutting-edge polymer technology, this specialized foam sheet delivers consistent performance in challenging environments where traditional damping materials often fall short. Its unique cellular structure provides optimal energy dissipation while maintaining structural integrity under repeated stress cycles, ensuring long-term operational efficiency for mission-critical applications.

Product Overview

The Professional Grade Rogers Foam Sheet High Impact Resistance for Vibration Noise Damping Engineering is engineered using advanced closed-cell foam technology that delivers exceptional mechanical properties and environmental resistance. This high-performance material features a sophisticated polymer matrix that provides superior energy absorption characteristics while maintaining excellent dimensional stability across a wide temperature range.

Built to meet the stringent demands of professional engineering applications, this foam sheet demonstrates remarkable resilience against mechanical stress, chemical exposure, and environmental factors that commonly affect industrial equipment. The material's innovative composition allows it to function effectively as both a vibration isolator and noise dampener, making it a versatile solution for complex engineering challenges where multiple performance criteria must be simultaneously satisfied.

The foam's advanced cellular architecture enables efficient energy dissipation through controlled deformation, effectively converting kinetic energy into heat while preventing damage to sensitive components. This characteristic makes it particularly valuable in applications where equipment protection and operational continuity are paramount concerns for system designers and maintenance professionals.

Features & Benefits

Superior Impact Resistance Technology

The foam sheet incorporates proprietary impact resistance technology that provides exceptional protection against sudden mechanical shocks and sustained vibrational forces. This advanced capability stems from the material's optimized cell structure, which allows for controlled compression and rapid recovery without permanent deformation. The result is a damping solution that maintains consistent performance characteristics throughout its operational lifecycle, even under severe loading conditions.

Advanced Noise Attenuation Properties

Engineered with acoustic engineering principles in mind, this Professional Grade Rogers Foam Sheet High Impact Resistance for Vibration Noise Damping Engineering delivers superior sound dampening performance across a broad frequency spectrum. The material effectively reduces both airborne and structure-borne noise transmission, making it ideal for applications where acoustic comfort and regulatory compliance are essential requirements. Its sound absorption coefficient remains stable across varying environmental conditions, ensuring predictable acoustic performance.

Enhanced Environmental Durability

The foam demonstrates exceptional resistance to environmental stressors including temperature fluctuations, humidity variations, and chemical exposure. This durability ensures reliable performance in outdoor applications, marine environments, and industrial settings where harsh conditions are commonplace. The material's inherent stability prevents degradation that commonly affects conventional foam materials, resulting in extended service life and reduced maintenance requirements.

Applications & Use Cases

The versatility of this Professional Grade Rogers Foam Sheet High Impact Resistance for Vibration Noise Damping Engineering makes it suitable for an extensive range of industrial and commercial applications. In automotive engineering, the material serves as an effective solution for reducing cabin noise and protecting sensitive electronic components from road-induced vibrations. Its ability to maintain performance under dynamic loading conditions makes it particularly valuable in suspension systems and engine compartment applications.

Within the aerospace industry, this foam sheet provides critical vibration isolation for avionics equipment and sensitive instrumentation where even minor disturbances can affect operational precision. The material's lightweight characteristics combined with superior dampening properties make it an optimal choice for weight-sensitive applications where performance cannot be compromised.

Industrial machinery applications benefit significantly from the foam's ability to reduce operational noise while protecting equipment from harmful vibrations. Manufacturing facilities utilize this material to improve workplace acoustic conditions while extending equipment service life through effective vibration management. The foam's chemical resistance properties make it particularly suitable for processing environments where exposure to industrial fluids and cleaning agents is routine.

Marine and offshore applications leverage the material's environmental durability and corrosion resistance to protect critical systems from the harsh maritime environment. The foam's ability to maintain its dampening characteristics in high-humidity conditions makes it invaluable for shipboard electronics and navigation equipment protection.

Quality Control & Compliance

Manufacturing processes for this Professional Grade Rogers Foam Sheet High Impact Resistance for Vibration Noise Damping Engineering adhere to rigorous quality control standards that ensure consistent material properties and reliable performance. Each production batch undergoes comprehensive testing protocols that verify mechanical properties, dimensional accuracy, and environmental resistance characteristics before release for distribution.

The material complies with relevant international standards for foam materials used in engineering applications, including fire resistance, chemical compatibility, and environmental safety requirements. These certifications provide assurance to engineers and procurement professionals that the material meets or exceeds industry benchmarks for safety and performance.

Continuous monitoring of production parameters ensures that every foam sheet meets the exacting specifications required for professional engineering applications. This commitment to quality extends throughout the manufacturing process, from raw material selection through final packaging, guaranteeing that customers receive materials that perform consistently across diverse application environments.

Customization & Branding Options

Understanding the diverse requirements of modern engineering projects, this foam sheet system offers extensive customization capabilities to meet specific application needs. Thickness variations can be precisely controlled to optimize dampening characteristics for particular frequency ranges or loading conditions, allowing engineers to fine-tune system performance for optimal results.

Surface treatment options enhance the material's compatibility with various bonding systems and mounting configurations commonly encountered in industrial applications. These treatments can improve adhesion characteristics, provide enhanced chemical resistance, or modify surface texture to meet specific installation requirements without compromising the foam's core dampening properties.

Custom cutting and shaping services enable precise fabrication of foam components that integrate seamlessly into existing equipment designs or new product development projects. This capability reduces installation time and ensures optimal fit within complex assemblies where standard sheet materials might require extensive field modification.

Private labeling options support original equipment manufacturers and system integrators who require branded dampening solutions for their products. This service includes custom packaging designs that align with corporate branding requirements while maintaining the professional presentation expected in B2B markets.

Packaging & Logistics Support

The foam sheets are protected during transit through specialized packaging systems designed to prevent damage while minimizing environmental impact. Protective wrapping maintains material cleanliness and prevents contamination that could affect bonding performance or surface quality in critical applications.

Palletization methods optimize shipping efficiency while ensuring that foam sheets arrive in perfect condition regardless of transportation mode or distance. Special attention to load distribution prevents compression damage that could affect the material's cellular structure and subsequent performance characteristics.

Inventory management support includes flexible ordering options that accommodate both project-specific requirements and ongoing production needs. This approach helps customers maintain optimal stock levels while avoiding the costs associated with excess inventory or production delays caused by material shortages.

International shipping capabilities ensure that this Professional Grade Rogers Foam Sheet High Impact Resistance for Vibration Noise Damping Engineering reaches customers worldwide with appropriate documentation and regulatory compliance for smooth customs clearance. Comprehensive tracking systems provide visibility throughout the logistics chain, enabling precise delivery planning for time-sensitive projects.

Why Choose Us

Our organization brings decades of experience in advanced materials engineering and global supply chain management to serve customers across multiple industries and geographic regions. This extensive background enables us to understand the complex requirements of modern engineering applications and provide solutions that consistently exceed performance expectations.

As a recognized custom tin box supplier and comprehensive metal packaging manufacturer, we have developed sophisticated quality management systems that extend across all product categories. Our expertise in precision manufacturing and attention to detail ensures that every foam sheet meets the exacting standards required for professional engineering applications.

International partnerships with leading material science organizations keep our product development at the forefront of industry innovation. This collaborative approach ensures that our customers have access to the latest advances in dampening technology while benefiting from proven manufacturing excellence that has earned recognition in global markets.

Technical support services provide customers with expert guidance throughout the material selection and application process. Our engineering team works closely with customers to optimize material specifications for specific applications, ensuring that performance objectives are achieved while maintaining cost effectiveness. This consultative approach has established long-term relationships with customers who value both product quality and technical expertise.

Conclusion

The Professional Grade Rogers Foam Sheet High Impact Resistance for Vibration Noise Damping Engineering represents a superior solution for demanding applications where vibration control, noise reduction, and impact resistance are critical performance requirements. Its advanced polymer technology, combined with proven manufacturing excellence and comprehensive technical support, makes it the optimal choice for engineers and manufacturers who refuse to compromise on quality or performance. The material's versatility across multiple industries, coupled with extensive customization options and reliable global logistics support, positions it as an indispensable component for modern engineering projects that demand both immediate performance and long-term reliability in challenging operational environments.

Polyurethane Foam: The Versatile High-Performance Sealing and Cushioning Material

Color |

Density |

Hardness |

Temperature Range |

Certifications |

Black

|

100~480 kg/m³

|

3~50 Shore 00/Shore A |

-20°C to +90°C

|

RoHS, REACH, UL94 HF-1 Flame Retardant Standards |

* Electronics & Appliances: Sealing gaskets for control panels, shock-absorbing pads for sensitive components, battery padding.

* Automotive Industry: Sealing for doors, windows, and lights; sound insulation and vibration damping in interiors.

* Medical Equipment: Cushioning for medical devices, sealing for enclosures, providing comfort and protection.

Invention Patent

System certification

Company Profile

We cater primarily to the consumer electronics, communication networks, and emerging energy vehicle sectors. To back ourcommitment to quality and innovation, we have established a national production base across four strategic locations:

1. A 1,000-square-meter new material formula R&D center in Shenzhen.

2. A 2,000-square-meter innovative grounding wrapping production plant in Dongguan.

3. A 10,000-square-meter conductive shielding tape coating plant in Hunan.

4. A 1,000-square-meter magnetron sputtering continuous gold/tin plating plant in Shandong.

As the only vertically integrated integrator in China offering electroplating, coating, and processing capabilities, we strive to become a leading innovator and provider of core values within the materials industry chain. Our ultimate goal is to be a long-term trusted solution provider and partner for our customers in addressing their challenges.

FAQ

We are based in Guangdong, China, start from 2011,sell to South Asia(10.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

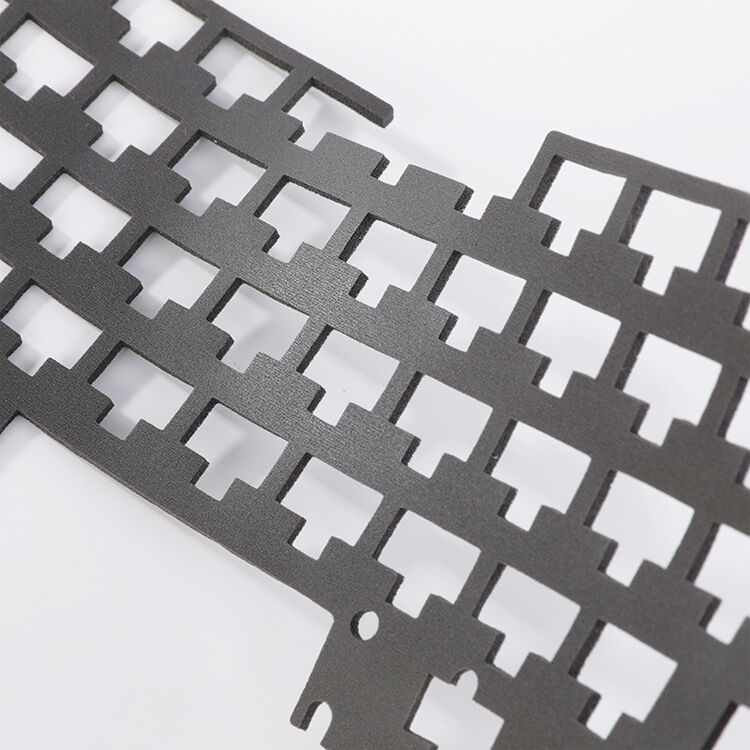

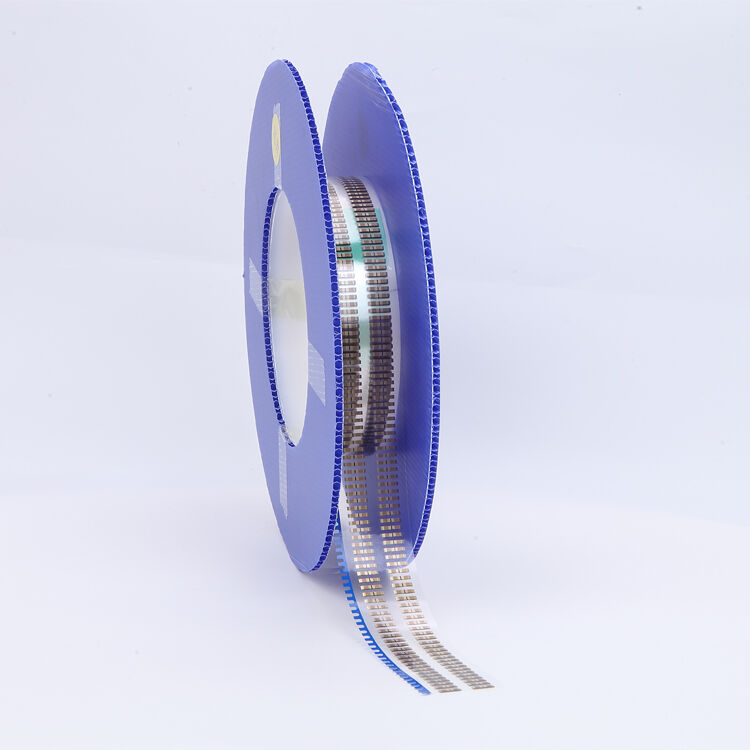

Shielding tape,Adhesive tapes,Waterproof and breathable membrane,Customized production,Raw material die-cutting

4. why should you buy from us not from other suppliers?

Shenzhen Johan Material Tech Co., Ltd. was established in 2011, and is an innovative national high-tech enterprise providing

innovative EMC (electromagnetic compatibility) grounding elastomers and customized tape solutions for the electronics indus

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency: USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken: English,Chinese