Introduction

In today's rapidly advancing electronics industry, electromagnetic interference and electrostatic discharge pose significant challenges to device performance and reliability. The Professional Grade Conductive Sponge Foam Gasket for EMI Shielding With Adhesive ESD Safe Die Cut Electrical Grounding represents a cutting-edge solution designed to address these critical concerns. This specialized gasket combines advanced conductive materials with precision engineering to deliver superior electromagnetic shielding and electrostatic discharge protection across diverse industrial applications.

As electronic devices become increasingly sophisticated and compact, the need for reliable EMI shielding solutions has never been more pronounced. This professional-grade gasket offers exceptional versatility, combining the benefits of conductive foam technology with convenient adhesive backing and precise die-cut manufacturing. Whether deployed in telecommunications equipment, medical devices, aerospace systems, or consumer electronics, this gasket provides consistent performance and long-term durability in demanding operational environments.

Product Overview

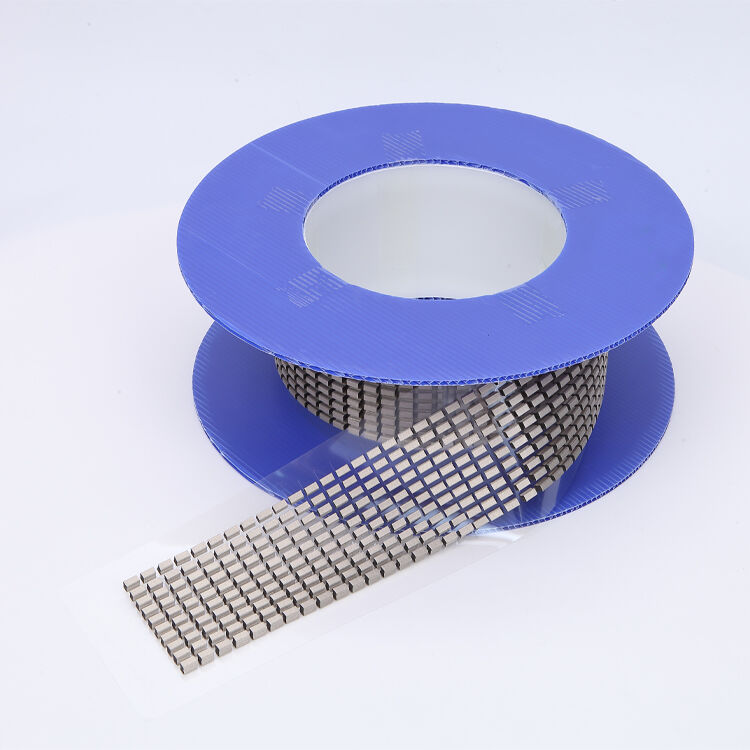

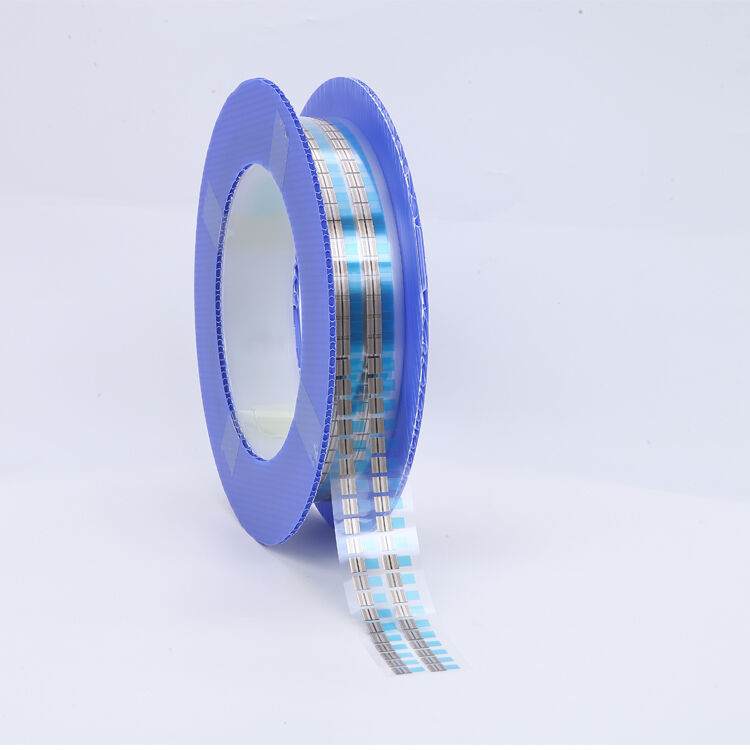

The Professional Grade Conductive Sponge Foam Gasket for EMI Shielding With Adhesive ESD Safe Die Cut Electrical Grounding features a sophisticated multi-layer construction that maximizes both electromagnetic shielding effectiveness and electrostatic discharge protection. The conductive sponge foam core utilizes advanced materials that maintain excellent conductivity while providing superior compression and recovery characteristics. This unique combination ensures reliable sealing performance across extended operational periods.

The gasket's adhesive backing system employs specially formulated compounds that deliver strong initial adhesion while remaining repositionable during installation phases. This feature significantly reduces installation time and minimizes the risk of application errors. The die-cut precision manufacturing process ensures consistent dimensional accuracy and clean edges, facilitating seamless integration into existing assembly processes without requiring additional machining or modification steps.

ESD safety represents a fundamental design priority throughout the gasket's construction. The carefully balanced conductive properties provide controlled static discharge pathways while maintaining optimal electromagnetic shielding performance. This dual-functionality approach eliminates the need for separate ESD protection components, streamlining system design and reducing overall component costs.

Features & Benefits

Advanced Conductive Technology

The gasket incorporates state-of-the-art conductive materials that ensure consistent electrical performance across varying environmental conditions. The conductive pathways remain stable through temperature fluctuations, humidity variations, and mechanical stress, providing reliable electromagnetic interference suppression throughout the product lifecycle. The foam structure maintains optimal compression characteristics while preserving electrical continuity, ensuring effective shielding even under dynamic loading conditions.

Superior Adhesive Performance

The integrated adhesive system delivers exceptional bonding strength to various substrate materials including metals, plastics, and composite surfaces. The adhesive formulation resists degradation from environmental exposure, maintaining secure attachment over extended periods. The controlled adhesive flow characteristics prevent contamination of sensitive electronic components while ensuring complete gasket-to-substrate contact for optimal shielding effectiveness.

Precision Die-Cut Manufacturing

Each gasket undergoes precision die-cutting processes that deliver exact dimensional specifications and clean, sealed edges. This manufacturing approach eliminates material fraying and ensures consistent compression characteristics across the entire gasket perimeter. The precise cutting also enables complex geometric shapes and intricate cutout patterns, accommodating diverse design requirements without compromising performance integrity.

ESD Safety Integration

The gasket's ESD-safe design provides controlled static discharge pathways that protect sensitive electronic components from electrostatic damage. The balanced conductivity prevents charge accumulation while maintaining effective electromagnetic shielding properties. This integrated approach simplifies system design by combining EMI shielding and ESD protection in a single component solution.

Applications & Use Cases

The Professional Grade Conductive Sponge Foam Gasket for EMI Shielding With Adhesive ESD Safe Die Cut Electrical Grounding serves critical functions across numerous industries and applications. In telecommunications infrastructure, these gaskets provide essential EMI shielding for base stations, network equipment, and signal processing systems. The gaskets maintain signal integrity by preventing electromagnetic interference between adjacent circuits and external sources, ensuring reliable communication performance.

Medical device manufacturing represents another significant application area where this gasket technology excels. The combination of EMI shielding and ESD protection proves essential for sensitive diagnostic equipment, patient monitoring systems, and therapeutic devices. The gasket's biocompatible materials and reliable sealing properties support compliance with stringent medical device regulations while maintaining optimal electromagnetic performance.

Aerospace and defense applications benefit from the gasket's ability to perform reliably in extreme environmental conditions. The robust construction withstands temperature variations, vibration, and atmospheric pressure changes while maintaining consistent electromagnetic shielding effectiveness. The lightweight foam construction contributes to overall system weight reduction, a critical consideration in aerospace applications.

Consumer electronics manufacturers utilize these gaskets in smartphones, tablets, laptops, and other portable devices where space constraints demand compact, efficient EMI shielding solutions. The thin profile and flexible characteristics enable integration into tight packaging while providing comprehensive electromagnetic protection. The ESD-safe properties protect sensitive integrated circuits during manufacturing and assembly processes.

Quality Control & Compliance

Manufacturing excellence forms the foundation of every Professional Grade Conductive Sponge Foam Gasket for EMI Shielding With Adhesive ESD Safe Die Cut Electrical Grounding produced. Comprehensive quality control protocols ensure consistent material properties, dimensional accuracy, and performance characteristics across all production batches. Advanced testing procedures validate electromagnetic shielding effectiveness, electrical conductivity, adhesive strength, and environmental resistance throughout the manufacturing process.

The gaskets undergo rigorous environmental testing to verify performance under various operational conditions. Temperature cycling tests confirm material stability and adhesive integrity across expected operating ranges. Humidity exposure testing validates moisture resistance and long-term dimensional stability. Mechanical testing verifies compression and recovery characteristics under repeated loading cycles.

Compliance with international standards represents a fundamental commitment throughout the product development and manufacturing processes. The gaskets meet relevant electromagnetic compatibility requirements and environmental safety standards. Material composition documentation supports regulatory compliance requirements across different markets and applications. Traceability systems maintain comprehensive records of material sources, manufacturing parameters, and quality test results.

Customization & Branding Options

Recognizing the diverse requirements of modern electronics manufacturing, extensive customization capabilities support unique application needs and design specifications. The die-cutting process accommodates complex geometric shapes, multiple cutouts, and intricate contour profiles without compromising material properties or performance characteristics. Custom thickness options enable optimization for specific compression requirements and available packaging space.

Material formulation adjustments allow fine-tuning of electrical, mechanical, and environmental properties to match specific application requirements. Conductivity levels can be optimized for particular EMI shielding effectiveness targets while maintaining ESD safety characteristics. Adhesive selection options accommodate different substrate materials and environmental exposure conditions.

Private labeling and custom packaging solutions support distributor and integrator branding requirements. Professional packaging design reinforces quality perception while providing clear product identification and application guidance. Technical documentation customization ensures alignment with specific market requirements and regulatory standards.

Packaging & Logistics Support

Comprehensive packaging solutions protect gasket integrity throughout storage, transportation, and handling processes. Specialized packaging materials prevent contamination, moisture exposure, and mechanical damage while maintaining adhesive properties until installation. Packaging configurations accommodate various order quantities and facilitate efficient inventory management for manufacturing operations.

Advanced logistics coordination ensures reliable delivery schedules that support just-in-time manufacturing requirements. Flexible shipping options accommodate urgent requirements while maintaining cost-effective solutions for standard deliveries. International shipping expertise navigates complex customs requirements and documentation needs for global supply chain integration.

Inventory management support includes forecasting assistance, buffer stock arrangements, and scheduled delivery programs that minimize supply disruptions. Technical support throughout the logistics process ensures proper handling and storage conditions that preserve gasket performance characteristics until final installation.

Why Choose Us

Our organization brings decades of specialized experience in advanced materials engineering and electromagnetic shielding solutions to every Professional Grade Conductive Sponge Foam Gasket for EMI Shielding With Adhesive ESD Safe Die Cut Electrical Grounding project. This extensive background enables deep understanding of complex application requirements and innovative solution development that addresses evolving industry challenges. Our global presence supports international customers with localized technical support and responsive service delivery.

As a recognized metal packaging manufacturer with comprehensive capabilities across diverse industrial sectors, we maintain strong relationships with materials suppliers, ensuring consistent raw material quality and supply chain reliability. Our position as a trusted custom tin box supplier demonstrates our commitment to precision manufacturing and quality excellence that extends across all product categories. These established capabilities as an OEM tin packaging solutions provider translate directly to superior gasket manufacturing expertise and customer support.

Continuous investment in advanced manufacturing technologies and quality systems ensures our position at the forefront of conductive gasket innovation. Our multi-industry expertise spans telecommunications, medical devices, aerospace, automotive, and consumer electronics, providing comprehensive understanding of diverse application requirements. This broad experience base enables rapid solution development and effective technical support for complex shielding challenges.

Collaborative partnerships with leading technology companies worldwide demonstrate our capability to support high-volume production requirements while maintaining exceptional quality standards. Our role as a reliable metal packaging supplier across international markets reflects our commitment to consistent performance and customer satisfaction that characterizes every business relationship.

Conclusion

The Professional Grade Conductive Sponge Foam Gasket for EMI Shielding With Adhesive ESD Safe Die Cut Electrical Grounding represents the pinnacle of electromagnetic shielding technology, combining advanced materials science with precision manufacturing to deliver superior performance across demanding applications. This innovative gasket solution addresses the critical challenges of electromagnetic interference and electrostatic discharge protection while providing the convenience and reliability that modern electronics manufacturing requires. The integration of conductive foam technology, high-performance adhesives, and precision die-cutting creates a comprehensive solution that simplifies system design while enhancing overall electromagnetic compatibility. Through continuous innovation and unwavering commitment to quality excellence, this gasket technology supports the advancement of electronic systems across industries, enabling the development of more reliable, efficient, and sophisticated devices that drive technological progress forward.

Johan ECF (Elastic Conductive Foam)

Technical Data Sheet

|

Updated: May,2021

|

||

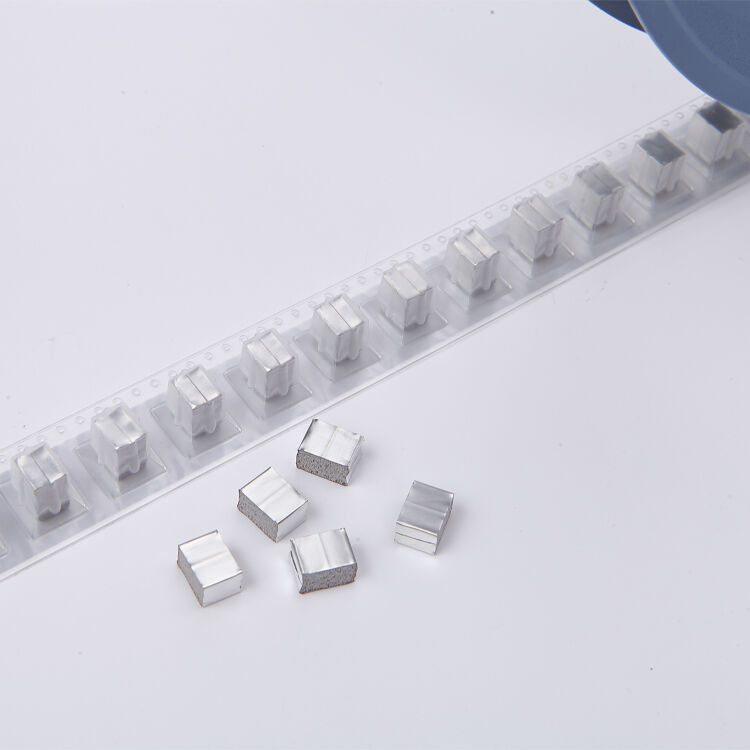

Description

|

This grounding foam is made of high-rebound elastomer base and super thin conductive fabric or film and suitable for high requirement grounding in super thin space. Due to its unique structure, it shows low electrical resistance and stable physical properties even after tough environment test. |

||

Structure

Application

Typical Physical Properties |

The following technical information and data should be considered representative or typical only and should not be used for specification purposes. |

Compression Rate |

0% |

30% |

50% |

70% |

Through-Resistance(Ω) |

0.179 |

0.080 |

0.051 |

0.045 |

Compression Rate |

0% |

30% |

50% |

70% |

Through-Resistance(Ω) |

0.201 |

0.115 |

0.070 |

0.058 |

Other dimension could be customized per demand.

(Fabric/Film with Au-plating work better with high refresh rate display including LCD and provide more stable performance over time)

(Working Height: 0.20mm ECF-SF-05S3 Fabric-Ni-Plating)

(Working Height: 0.30mm ECF-SF-07S3 Fabric-Ni-Plating)

(Working Height: 0.20mm ECF-SF-05S3GP Fabric-Au-Plating )

(Working Height: 0.33mm ECF-SF-07S3GP Fabric-Au-Plating)

Company Profile

We cater primarily to the consumer electronics, communication networks, and emerging energy vehicle sectors. To back ourcommitment to quality and innovation, we have established a national production base across four strategic locations:

1. A 1,000-square-meter new material formula R&D center in Shenzhen.

2. A 2,000-square-meter innovative grounding wrapping production plant in Dongguan.

3. A 10,000-square-meter conductive shielding tape coating plant in Hunan.

4. A 1,000-square-meter magnetron sputtering continuous gold/tin plating plant in Shandong.

As the only vertically integrated integrator in China offering electroplating, coating, and processing capabilities, we strive to become a leading innovator and provider of core values within the materials industry chain. Our ultimate goal is to be a long-term trusted solution provider and partner for our customers in addressing their challenges.

System certification

Invention Patent

FAQ

We are based in Guangdong, China, start from 2011,sell to South Asia(10.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Shielding tape,Adhesive tapes,Waterproof and breathable membrane,Customized production,Raw material die-cutting

4. why should you buy from us not from other suppliers?

Shenzhen Johan Material Tech Co., Ltd. was established in 2011, and is an innovative national high-tech enterprise providing

innovative EMC (electromagnetic compatibility) grounding elastomers and customized tape solutions for the electronics indus

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency: USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken: English,Chinese