Introduction

In today's rapidly evolving manufacturing landscape, protecting sensitive components during transportation and operation has become increasingly critical. The Precision Cushioning Poron Foam Excellent Shock Absorption for Delicate Electronics Automotive Parts represents a breakthrough in protective packaging technology, offering unparalleled defense against impact, vibration, and environmental stresses. This advanced foam solution addresses the growing demand from manufacturers, distributors, and OEM suppliers who require reliable protection for their most valuable electronic devices and automotive components.

Modern industrial applications demand materials that not only provide exceptional cushioning properties but also maintain consistent performance across varying environmental conditions. Our premium Poron foam technology delivers superior shock absorption characteristics while remaining lightweight and versatile enough to accommodate diverse packaging requirements. Whether protecting sensitive circuit boards, precision instruments, or critical automotive electronics, this innovative cushioning solution ensures product integrity throughout the entire supply chain.

Product Overview

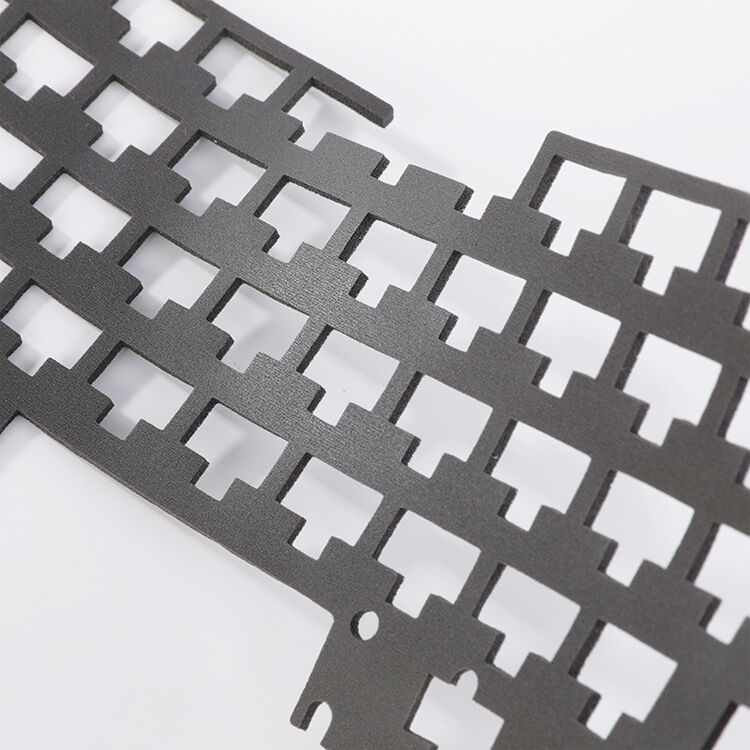

The Precision Cushioning Poron Foam Excellent Shock Absorption for Delicate Electronics Automotive Parts utilizes cutting-edge microcellular urethane technology to create a superior protective barrier. This specialized foam material exhibits exceptional energy absorption properties, effectively dissipating impact forces that could otherwise damage sensitive components. The unique cellular structure provides consistent cushioning performance across multiple compression cycles, making it ideal for reusable packaging applications.

Unlike traditional foam materials that may degrade over time or lose their protective properties, this advanced Poron foam maintains its shock absorption capabilities throughout extended use periods. The material's inherent resistance to compression set ensures reliable protection, while its excellent memory properties allow it to return to its original thickness after each compression cycle. This durability makes it particularly valuable for manufacturers seeking long-term protective packaging solutions that deliver consistent results.

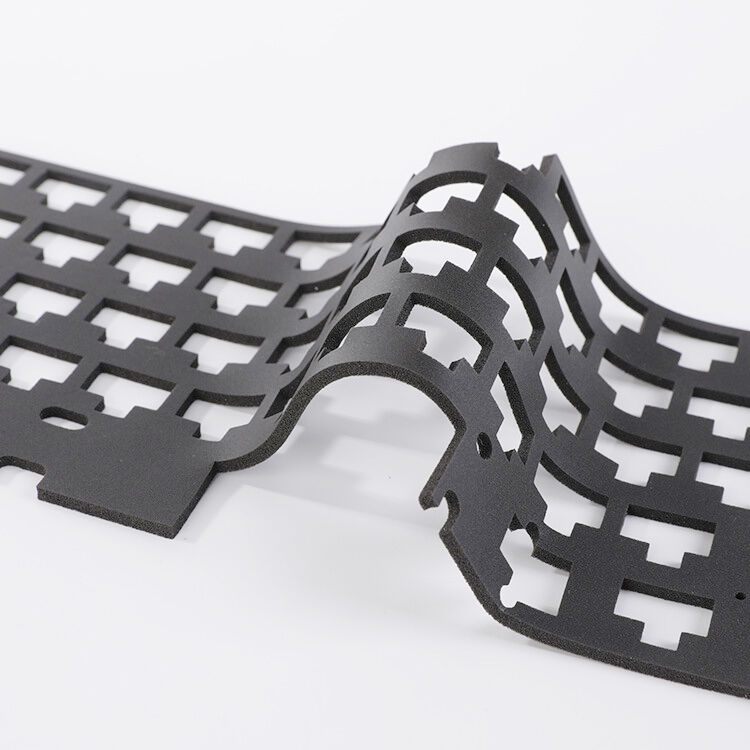

The foam's precision-engineered composition offers remarkable versatility in application design. Its compatibility with various die-cutting and fabrication techniques enables manufacturers to create custom-fitted protective inserts that perfectly conform to specific product geometries. This precision fitting capability significantly enhances protection effectiveness while optimizing package space utilization, a critical consideration for efficient logistics and cost management.

Features & Benefits

Superior Shock Absorption Technology

The core strength of this Precision Cushioning Poron Foam lies in its exceptional shock absorption characteristics. The material's advanced microcellular structure creates thousands of tiny air pockets that work collectively to absorb and dissipate impact energy. This sophisticated energy management system effectively protects delicate electronics and automotive components from damage caused by drops, vibrations, and handling stresses during transportation and storage.

The foam's shock absorption properties remain consistent across varying temperature ranges, ensuring reliable protection in diverse environmental conditions. This temperature stability is particularly valuable for automotive applications where components may experience extreme temperature variations during shipping or storage. The material's ability to maintain its protective characteristics under these conditions makes it an ideal choice for international shipping applications.

Enhanced Durability and Longevity

Exceptional durability sets this Poron foam apart from conventional cushioning materials. The material's resistance to fatigue and compression set ensures that protective properties are maintained even after repeated use. This longevity translates into significant cost savings for manufacturers who utilize reusable packaging systems, as the foam continues to provide reliable protection throughout multiple shipping cycles.

The chemical stability of the foam material ensures compatibility with a wide range of electronic and automotive components. Its non-reactive nature prevents potential damage from chemical interactions, while its low outgassing properties make it suitable for sensitive electronic applications where contamination must be minimized. This chemical inertness extends the service life of both the foam and the protected components.

Precision Engineering and Customization

The material's excellent machinability allows for precise customization to meet specific application requirements. Advanced die-cutting capabilities enable the creation of intricate shapes and cavities that provide perfect-fit protection for complex component geometries. This precision engineering ensures optimal shock absorption while minimizing package size and weight, contributing to more efficient logistics operations.

Surface texture options provide additional customization possibilities, allowing manufacturers to optimize grip characteristics and prevent component movement within packaging. The material's ability to accept various surface treatments and coatings further enhances its versatility, enabling integration with specialized packaging systems and automated handling equipment.

Applications & Use Cases

The versatility of Precision Cushioning Poron Foam Excellent Shock Absorption for Delicate Electronics Automotive Parts makes it suitable for an extensive range of industrial applications. In the electronics industry, this advanced foam material provides critical protection for sensitive components such as printed circuit boards, semiconductor devices, displays, and precision instruments. The foam's anti-static properties and low ionic content make it particularly well-suited for protecting electronic components that are susceptible to electrostatic discharge damage.

Automotive manufacturers and suppliers rely on this superior cushioning solution to protect various electronic control modules, sensors, and delicate automotive components during transportation and assembly processes. The material's resistance to automotive fluids and temperature extremes ensures reliable protection throughout the automotive supply chain. From engine control units to advanced driver assistance system components, this foam provides the precision protection required for today's sophisticated automotive electronics.

Medical device manufacturers utilize this advanced foam technology to protect sensitive diagnostic equipment, surgical instruments, and electronic monitoring devices. The material's biocompatibility and cleanliness characteristics make it suitable for medical applications where contamination control is paramount. The foam's ability to provide consistent cushioning while maintaining sterile packaging integrity makes it invaluable for medical device distribution.

Aerospace and defense applications benefit from the foam's exceptional performance under extreme conditions. The material's lightweight properties contribute to overall weight reduction goals while providing the robust protection required for sensitive avionics and electronic warfare systems. Its stability under varying atmospheric conditions and resistance to vibration make it ideal for protecting components during air transportation and field deployment.

Industrial equipment manufacturers use this cushioning solution to protect precision measurement instruments, control systems, and sensitive manufacturing equipment components. The foam's ability to provide consistent protection while accommodating thermal expansion and contraction makes it particularly valuable for equipment that operates across varying temperature ranges. Its compatibility with industrial cleaning processes ensures long-term reliability in demanding manufacturing environments.

Quality Control & Compliance

Rigorous quality control measures ensure that every batch of Precision Cushioning Poron Foam meets the highest standards for shock absorption performance and material consistency. Our comprehensive testing protocols evaluate key characteristics including compression force deflection, energy absorption, and recovery properties. These standardized tests guarantee that the foam delivers predictable protection performance across all applications, providing manufacturers with the confidence needed for critical component protection.

Material composition and purity standards are maintained through advanced manufacturing processes that eliminate contaminants and ensure consistent cellular structure throughout the foam. Regular sampling and analysis verify that chemical properties remain within specified parameters, ensuring compatibility with sensitive electronic and automotive applications. This attention to material purity is particularly important for applications where outgassing or chemical interaction could compromise component performance.

Environmental compliance considerations are integrated throughout the manufacturing process, with materials selected and processed to meet international environmental standards. The foam's recyclability and environmental impact characteristics support sustainable packaging initiatives while maintaining superior protective performance. This environmental responsibility aligns with the growing emphasis on sustainable manufacturing practices across global markets.

Traceability systems track material properties and performance characteristics throughout the production process, enabling rapid identification and resolution of any quality variations. This comprehensive documentation supports customer quality requirements and facilitates integration with existing quality management systems. The availability of detailed material property data enables engineers to optimize packaging designs and ensure reliable protection performance.

Customization & Branding Options

Extensive customization capabilities allow manufacturers to tailor the Precision Cushioning Poron Foam to meet specific application requirements and branding objectives. Advanced die-cutting and fabrication techniques enable the creation of complex geometries that provide optimal protection while accommodating unique product shapes and packaging constraints. This precision customization ensures perfect fit and maximum protection efficiency for each application.

Color customization options provide opportunities for brand integration and component identification within packaging systems. Custom colors can be incorporated without compromising the foam's protective properties, enabling manufacturers to maintain brand consistency throughout their packaging solutions. This visual customization capability is particularly valuable for products requiring clear component identification or brand differentiation.

Surface treatment options extend customization possibilities to include specialized textures, adhesive compatibility, and grip characteristics. These surface modifications can be tailored to work with automated packaging equipment, anti-slip requirements, or specific handling needs. The ability to customize surface properties while maintaining core cushioning performance provides manufacturers with comprehensive design flexibility.

Thickness variations and density options allow optimization for specific protection requirements and space constraints. Engineers can select the ideal combination of cushioning performance and package efficiency, ensuring optimal protection while minimizing shipping costs and storage requirements. This flexibility in material specifications enables manufacturers to achieve the perfect balance between protection and efficiency for each application.

Packaging & Logistics Support

Comprehensive packaging and logistics support ensures that Precision Cushioning Poron Foam reaches customers in optimal condition while supporting efficient integration into manufacturing processes. The foam material is carefully packaged using protective methods that prevent contamination and maintain material properties during transportation. This attention to packaging integrity ensures that customers receive materials ready for immediate use in their production environments.

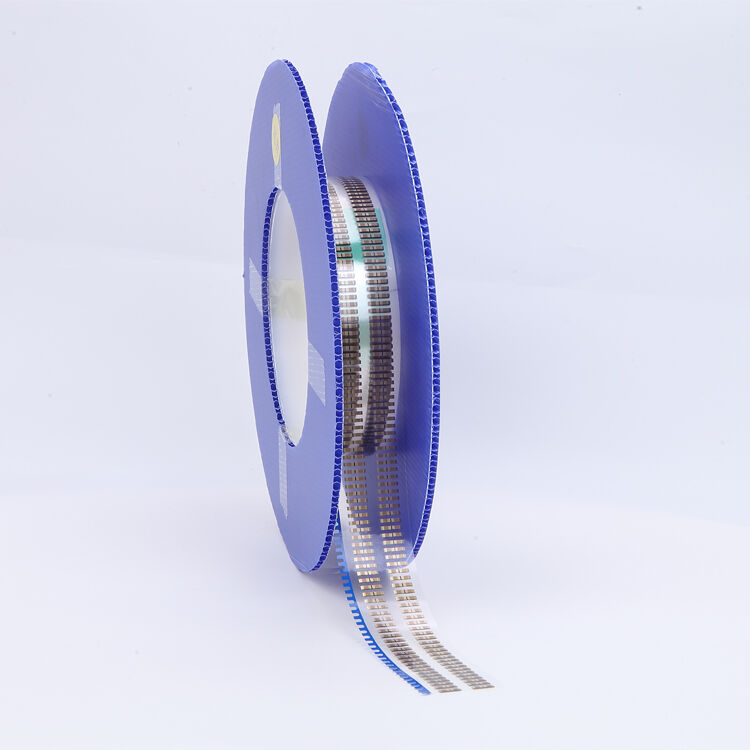

Flexible packaging configurations accommodate varying production requirements and inventory management preferences. Materials can be supplied in formats optimized for automated die-cutting operations, manual fabrication processes, or direct integration into packaging systems. This flexibility in supply formats enables manufacturers to optimize their production workflows while maintaining consistent material quality.

Global logistics capabilities ensure reliable delivery to international markets while maintaining material integrity throughout the shipping process. Specialized handling procedures protect the foam from environmental extremes and physical damage during long-distance transportation. This international logistics expertise supports manufacturers with global operations who require consistent material availability across multiple production locations.

Inventory management support includes forecasting assistance and flexible delivery scheduling to help manufacturers optimize their material planning and reduce carrying costs. Technical support services provide guidance on material selection, fabrication techniques, and application optimization to ensure successful implementation. This comprehensive support approach helps customers achieve optimal results while minimizing implementation challenges.

Why Choose Us

Our commitment to delivering superior Precision Cushioning Poron Foam solutions is backed by extensive experience serving international markets and diverse industrial applications. With decades of expertise in advanced foam technology and protective packaging solutions, we have established ourselves as a trusted partner for manufacturers requiring reliable component protection. Our global presence enables us to provide consistent support and material availability to customers worldwide, ensuring seamless integration with international production and distribution networks.

As a recognized custom packaging supplier, we understand the unique challenges faced by manufacturers in protecting sensitive components while optimizing logistics efficiency. Our comprehensive approach combines advanced material science with practical engineering support to deliver solutions that exceed customer expectations. This expertise extends across multiple industries, enabling us to bring cross-industry insights and innovations to each application.

Our role as a specialized foam manufacturer encompasses not only material production but also application engineering and technical support services. This comprehensive capability ensures that customers receive not just superior materials but also the expertise needed to optimize their packaging designs and achieve maximum protection efficiency. Our collaborative approach helps customers develop innovative solutions that address their specific challenges while leveraging the latest advances in foam technology.

Quality assurance systems and continuous improvement processes ensure that our Precision Cushioning Poron Foam consistently meets the highest standards for performance and reliability. Regular investment in advanced manufacturing equipment and testing capabilities maintains our position at the forefront of foam technology development. This commitment to excellence provides customers with confidence in material performance and long-term supply reliability.

Conclusion

The Precision Cushioning Poron Foam Excellent Shock Absorption for Delicate Electronics Automotive Parts represents the pinnacle of protective packaging technology, offering unmatched combination of superior shock absorption, durability, and customization capabilities. Its advanced microcellular structure and precision engineering make it the ideal choice for manufacturers requiring reliable protection for sensitive electronic and automotive components. The material's exceptional performance characteristics, combined with comprehensive customization options and global logistics support, provide manufacturers with a complete solution for their most demanding protective packaging requirements. This innovative foam technology continues to set new standards in component protection while supporting the evolving needs of modern manufacturing and distribution operations.

Polyurethane Foam: The Versatile High-Performance Sealing and Cushioning Material

Color |

Density |

Hardness |

Temperature Range |

Certifications |

Black

|

100~480 kg/m³

|

3~50 Shore 00/Shore A |

-20°C to +90°C

|

RoHS, REACH, UL94 HF-1 Flame Retardant Standards |

* Electronics & Appliances: Sealing gaskets for control panels, shock-absorbing pads for sensitive components, battery padding.

* Automotive Industry: Sealing for doors, windows, and lights; sound insulation and vibration damping in interiors.

* Medical Equipment: Cushioning for medical devices, sealing for enclosures, providing comfort and protection.

Invention Patent

System certification

Company Profile

We cater primarily to the consumer electronics, communication networks, and emerging energy vehicle sectors. To back ourcommitment to quality and innovation, we have established a national production base across four strategic locations:

1. A 1,000-square-meter new material formula R&D center in Shenzhen.

2. A 2,000-square-meter innovative grounding wrapping production plant in Dongguan.

3. A 10,000-square-meter conductive shielding tape coating plant in Hunan.

4. A 1,000-square-meter magnetron sputtering continuous gold/tin plating plant in Shandong.

As the only vertically integrated integrator in China offering electroplating, coating, and processing capabilities, we strive to become a leading innovator and provider of core values within the materials industry chain. Our ultimate goal is to be a long-term trusted solution provider and partner for our customers in addressing their challenges.

FAQ

We are based in Guangdong, China, start from 2011,sell to South Asia(10.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Shielding tape,Adhesive tapes,Waterproof and breathable membrane,Customized production,Raw material die-cutting

4. why should you buy from us not from other suppliers?

Shenzhen Johan Material Tech Co., Ltd. was established in 2011, and is an innovative national high-tech enterprise providing

innovative EMC (electromagnetic compatibility) grounding elastomers and customized tape solutions for the electronics indus

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency: USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken: English,Chinese