Introduction

In today's demanding industrial environments, professionals require reliable sealing solutions that can withstand extreme conditions while maintaining superior performance. The Industrial Grade Aluminum Foil Tape With High Adhesion for Pipe Sealing Roof Repair Waterproof and Flame Retardant represents a breakthrough in advanced adhesive technology, specifically engineered to meet the rigorous demands of commercial construction, HVAC installation, and industrial maintenance applications. This premium aluminum foil tape combines exceptional adhesive strength with multi-functional protective properties, making it an indispensable tool for contractors, facility managers, and maintenance professionals worldwide.

Developed through extensive research and testing, this industrial-grade sealing solution addresses the critical need for versatile, high-performance tape that can handle diverse environmental challenges. From temperature fluctuations to moisture exposure and fire safety requirements, this aluminum foil tape delivers comprehensive protection while ensuring long-lasting adhesion across various substrate materials. The innovative formulation represents years of engineering expertise focused on creating a single product that can replace multiple specialized tapes in many applications.

Product Overview

This Industrial Grade Aluminum Foil Tape With High Adhesion for Pipe Sealing Roof Repair Waterproof and Flame Retardant features a sophisticated multi-layer construction that maximizes performance across diverse operating conditions. The aluminum foil backing provides exceptional tensile strength and conformability, allowing the tape to adapt seamlessly to irregular surfaces, joints, and connections commonly found in industrial and construction applications. The backing material exhibits excellent resistance to puncture and tearing, ensuring reliable performance even under mechanical stress.

The advanced adhesive system represents the core innovation of this professional-grade tape, utilizing proprietary polymer chemistry to achieve superior bonding strength across a wide range of substrates. This high-performance adhesive maintains its effectiveness across extreme temperature ranges while resisting degradation from UV exposure, chemical contact, and environmental contaminants. The adhesive formulation has been specifically optimized to provide instant initial tack combined with progressive bond strength development over time.

Beyond basic sealing capabilities, this aluminum foil tape incorporates specialized additives that enhance its flame retardant properties, making it suitable for applications where fire safety compliance is essential. The waterproof characteristics ensure complete moisture barrier protection, preventing water infiltration that could compromise structural integrity or create hazardous conditions in electrical installations.

Features & Benefits

Superior Adhesive Performance

The high adhesion formulation of this industrial aluminum foil tape delivers exceptional bonding strength that surpasses conventional sealing products in both initial grab and long-term holding power. This advanced adhesive system creates molecular-level bonds with substrate surfaces, resulting in permanent seals that resist peeling, lifting, or degradation over extended service periods. The adhesive maintains its effectiveness across temperature extremes, ensuring reliable performance in both heated and refrigerated environments.

Professional contractors appreciate the immediate tack properties that allow for precise positioning and adjustment during installation, while the progressive curing process develops maximum bond strength within hours of application. This dual-phase adhesion mechanism provides both installation convenience and long-term reliability, reducing the need for reapplication or maintenance interventions.

Multi-Functional Protective Properties

The waterproof barrier created by this Industrial Grade Aluminum Foil Tape With High Adhesion for Pipe Sealing Roof Repair Waterproof and Flame Retardant provides comprehensive moisture protection that prevents water infiltration, condensation damage, and humidity-related deterioration. This moisture barrier capability extends beyond surface water resistance to include protection against vapor transmission, making it ideal for applications requiring complete environmental sealing.

The flame retardant characteristics have been engineered to meet stringent fire safety requirements while maintaining the tape's primary sealing and adhesive functions. This multi-functional approach eliminates the need for separate flame-resistant treatments or coatings, simplifying installation procedures and reducing material costs for large-scale projects.

Exceptional Durability and Longevity

Constructed with premium aluminum foil backing, this tape exhibits outstanding resistance to environmental degradation factors including UV radiation, ozone exposure, and chemical contact. The metallic backing provides inherent stability against thermal cycling, preventing the cracking and brittleness that commonly affects polymer-based sealing materials over time. This durability translates into extended service life and reduced maintenance requirements for critical installations.

The combination of robust backing material and advanced adhesive chemistry creates a sealing system that maintains its integrity under continuous stress, vibration, and environmental exposure. This reliability makes it particularly valuable for applications where access for maintenance or replacement is difficult or costly.

Applications & Use Cases

The versatility of this Industrial Grade Aluminum Foil Tape With High Adhesion for Pipe Sealing Roof Repair Waterproof and Flame Retardant makes it indispensable across numerous industrial and commercial applications. In HVAC installations, the tape provides superior sealing for ductwork joints, connections, and penetrations, ensuring optimal system efficiency while preventing air leakage that reduces energy performance. The conformable nature of the aluminum backing allows for secure sealing around complex geometries and irregular surfaces commonly encountered in modern building systems.

Roofing applications benefit significantly from the waterproof and weather-resistant properties of this professional tape. Contractors rely on its ability to create permanent seals around roof penetrations, flashing details, and emergency repairs where immediate weather protection is essential. The flame retardant characteristics provide additional safety margin in roofing applications where hot work or electrical installations may present fire risks.

Pipe sealing applications across industrial facilities, commercial buildings, and infrastructure projects utilize the tape's ability to conform to cylindrical surfaces while maintaining complete circumferential sealing. The high adhesion properties ensure reliable attachment to various pipe materials including steel, copper, PVC, and composite materials commonly used in modern piping systems. This versatility eliminates the need for multiple specialized products in complex installations.

Industrial maintenance teams value the tape's effectiveness in emergency repair situations where rapid, reliable sealing is critical to maintaining operational continuity. The instant adhesion and waterproof barrier capabilities enable temporary repairs that can withstand operational stresses until permanent solutions can be implemented during scheduled maintenance windows.

Quality Control & Compliance

Manufacturing of this Industrial Grade Aluminum Foil Tape With High Adhesion for Pipe Sealing Roof Repair Waterproof and Flame Retardant follows rigorous quality control protocols that ensure consistent performance across all production batches. Advanced testing procedures verify adhesive strength, environmental resistance, and flame retardant properties throughout the manufacturing process, guaranteeing that each roll meets or exceeds established performance specifications.

Comprehensive quality assurance testing includes accelerated aging studies that simulate years of environmental exposure in controlled laboratory conditions. These tests validate the long-term stability of both the adhesive system and aluminum backing material, providing confidence in the tape's performance over extended service periods. Environmental testing protocols evaluate resistance to temperature cycling, humidity exposure, UV radiation, and chemical contact to ensure reliable performance across diverse operating conditions.

The flame retardant properties undergo specialized testing to verify compliance with relevant fire safety standards, ensuring that the tape meets or exceeds requirements for use in applications where fire resistance is mandatory. This testing includes both flame spread and smoke generation evaluations to provide comprehensive fire safety characterization.

Material traceability systems maintain detailed records of raw material sources, production parameters, and quality test results for each production lot, enabling rapid response to any quality concerns and supporting continuous improvement initiatives. This comprehensive approach to quality management ensures consistent product performance and customer satisfaction across global markets.

Customization & Branding Options

Understanding the diverse requirements of global markets, this aluminum foil tape platform supports extensive customization options to meet specific application needs and regional preferences. Width variations accommodate different sealing requirements from narrow precision applications to wide-area coverage needs, while length options provide flexibility for both small-scale repairs and large construction projects.

Adhesive formulation modifications can be implemented to optimize performance for specific substrates or environmental conditions. These customizations might include enhanced temperature resistance for extreme climate applications, improved chemical resistance for industrial environments, or modified tack properties for specialized installation requirements. Such flexibility ensures optimal performance across diverse global applications.

Private labeling and custom packaging solutions enable distributors and contractors to maintain brand consistency while offering this high-performance sealing solution to their customers. Custom printing options can include safety information, application instructions, or branding elements that enhance product recognition and professional appearance.

Technical documentation and application guidelines can be customized to address specific regional building codes, safety requirements, or installation practices. This localization ensures that users receive relevant, applicable information that supports successful project outcomes while maintaining compliance with local regulations and standards.

Packaging & Logistics Support

Professional packaging solutions for this Industrial Grade Aluminum Foil Tape With High Adhesion for Pipe Sealing Roof Repair Waterproof and Flame Retardant ensure product integrity throughout global distribution networks. Moisture-resistant packaging protects the adhesive system from humidity exposure during storage and transport, maintaining optimal performance characteristics until the tape is applied in field conditions.

Packaging configurations accommodate various distribution models from individual contractor purchases to large-scale commercial projects requiring bulk quantities. Compact packaging designs maximize shipping efficiency while protective materials prevent damage during handling and transport. Clear labeling and identification systems facilitate inventory management and ensure proper product selection for specific applications.

Storage recommendations and shelf life information provide guidance for maintaining product quality throughout the distribution chain. Proper storage conditions preserve both the aluminum backing integrity and adhesive performance, ensuring that end users receive tape that performs to full specifications regardless of storage duration.

International shipping compliance includes documentation and labeling that meets various regulatory requirements for hazardous materials classification, enabling smooth customs clearance and regulatory compliance across global markets. This comprehensive approach to packaging and logistics ensures reliable product availability worldwide.

Why Choose Us

Our company brings over two decades of experience in advanced adhesive technology development and manufacturing, with established market presence across multiple continents serving diverse industrial sectors. This extensive experience translates into deep understanding of real-world application requirements and the technical expertise necessary to deliver consistently superior products that exceed customer expectations in demanding professional environments.

As a recognized metal packaging supplier and custom solutions provider, we maintain comprehensive capabilities spanning product development, manufacturing, quality control, and global distribution. Our multi-industry expertise enables us to understand the interconnected requirements of construction, HVAC, industrial maintenance, and specialty applications, resulting in products that deliver exceptional versatility and performance across diverse professional applications.

Strategic partnerships with leading raw material suppliers and technology providers ensure access to the most advanced materials and manufacturing processes available in the global market. These relationships enable continuous product improvement and innovation while maintaining competitive positioning that benefits our distribution partners and end users worldwide.

Our commitment to sustainable manufacturing practices and environmental responsibility extends throughout our operations, from raw material selection through waste reduction and energy efficiency initiatives. This comprehensive approach to sustainability supports our customers' environmental objectives while maintaining the highest standards of product performance and reliability.

Technical support capabilities include application engineering assistance, custom product development, and comprehensive testing services that help customers optimize their sealing solutions for specific requirements. This consultative approach ensures successful project outcomes while building long-term partnerships based on mutual success and shared technical excellence.

Conclusion

The Industrial Grade Aluminum Foil Tape With High Adhesion for Pipe Sealing Roof Repair Waterproof and Flame Retardant represents the pinnacle of modern sealing technology, combining superior adhesive performance with comprehensive protective properties in a single, versatile product. Its exceptional ability to deliver reliable waterproof sealing, flame retardant protection, and long-term durability makes it an invaluable asset for professional contractors, maintenance teams, and facility managers worldwide. The advanced engineering behind this aluminum foil tape ensures consistent performance across diverse applications while providing the flexibility and reliability that modern construction and industrial projects demand. By choosing this premium sealing solution, professionals gain access to a proven product that simplifies inventory management, reduces installation time, and delivers superior long-term performance that protects critical infrastructure investments and ensures operational continuity across demanding industrial environments.

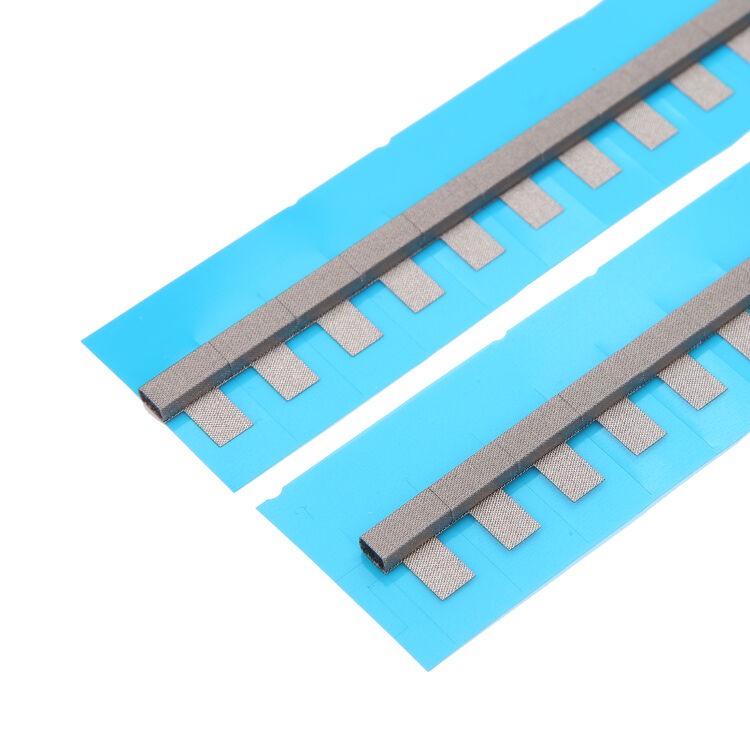

Professional EMI Shielding Tapes - Total Solution for RFI/ESD Protection

Excellent Shielding Performance |

Offers high shielding effectiveness over a wide frequency range, ideal for EMI, RFI, and ESD full protection. |

||||||

High Conductivity & Low Resistance |

Made from superior materials like nickel/copper coated fabric or pure copper foil, ensuring good electrical conductivity and reliable grounding. |

||||||

Flexible & Conformable |

Ultra-thin, flexible, and lightweight design allows for easy application on curved surfaces and tight spaces, such as internal circuit boards and flexible circuits. |

||||||

Customizable Solutions |

Available in custom sizes, shapes, and die-cuts (OEM/ODM supported). RoHS and REACH compliant to meet global environmental standards. |

||||||

Consumer Electronics |

Smartphones, laptops, gaming consoles, LCD displays, and 5G wireless chargers for internal circuit board shielding and high-speed HDMI signal protection. |

||||||

Automotive & Transportation |

Automotive electronics, autonomous vehicles LiDAR/Radar systems, and EV wireless chargers as part of robust EMC solutions. |

||||||

Telecom & Networking |

Networking equipment, 5G infrastructure, and cabinet shielding to ensure signal integrity and prevent interference. |

||||||

Industrial & Medical

|

Industrial control systems, power supplies, and sensitive medical electronic devices requiring reliable performance in demanding conditions. |

||||||

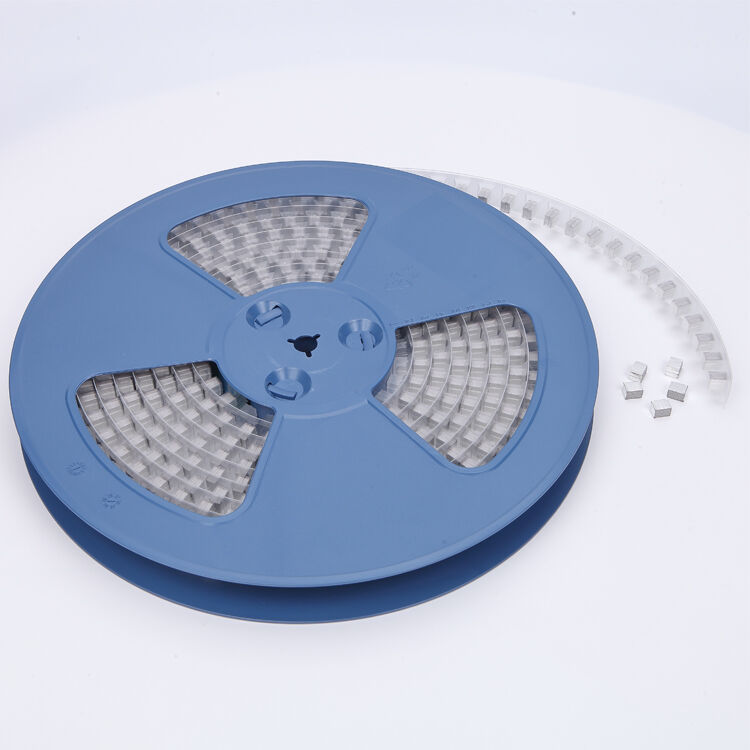

Available Types

Company Profile

We cater primarily to the consumer electronics, communication networks, and emerging energy vehicle sectors. To back ourcommitment to quality and innovation, we have established a national production base across four strategic locations:

1. A 1,000-square-meter new material formula R&D center in Shenzhen.

2. A 2,000-square-meter innovative grounding wrapping production plant in Dongguan.

3. A 10,000-square-meter conductive shielding tape coating plant in Hunan.

4. A 1,000-square-meter magnetron sputtering continuous gold/tin plating plant in Shandong.

As the only vertically integrated integrator in China offering electroplating, coating, and processing capabilities, we strive to become a leading innovator and provider of core values within the materials industry chain. Our ultimate goal is to be a long-term trusted solution provider and partner for our customers in addressing their challenges.

Invention Patent

System certification

FAQ

We are based in Guangdong, China, start from 2011,sell to South Asia(10.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Shielding tape,Adhesive tapes,Waterproof and breathable membrane,Customized production,Raw material die-cutting

4. why should you buy from us not from other suppliers?

Shenzhen Johan Material Tech Co., Ltd. was established in 2011, and is an innovative national high-tech enterprise providing

innovative EMC (electromagnetic compatibility) grounding elastomers and customized tape solutions for the electronics indus

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency: USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken: English,Chinese