Introduction

In today's rapidly evolving automotive electronics landscape, the demand for advanced thermal management solutions has never been more critical. As electronic components become increasingly sophisticated and compact, the need for reliable insulation materials that can withstand extreme temperatures while maintaining safety standards has become paramount. The High Temp PI Film Over Silicone Foam Flame Retardant Self Adhesive for Automotive Electronics represents a breakthrough in thermal interface technology, specifically engineered to address the complex challenges faced by automotive manufacturers and electronics integrators worldwide.

This innovative composite material combines the exceptional thermal properties of polyimide film with the cushioning capabilities of silicone foam, creating a versatile solution that excels in high-temperature environments. The flame retardant characteristics and self-adhesive backing make this product an ideal choice for applications where safety, reliability, and ease of installation are non-negotiable requirements.

Product Overview

The High Temp PI Film Over Silicone Foam Flame Retardant Self Adhesive for Automotive Electronics is a multi-layered composite material that delivers superior thermal management performance in demanding automotive applications. This engineered solution features a high-performance polyimide film layer bonded to a specialized silicone foam substrate, creating a material that effectively manages heat transfer while providing excellent electrical insulation properties.

The polyimide film component offers outstanding thermal stability and chemical resistance, making it suitable for use in environments where conventional materials would degrade or fail. The silicone foam layer provides compressibility and conformability, allowing the material to accommodate surface irregularities and maintain consistent thermal contact across varying component geometries. The self-adhesive backing eliminates the need for additional fasteners or adhesives, streamlining the installation process while ensuring secure attachment to various substrates.

This flame retardant formulation meets stringent automotive safety standards, providing peace of mind in applications where fire safety is a critical concern. The material's unique construction allows it to maintain its properties across a wide temperature range, making it suitable for both engine compartment applications and passenger cabin electronics where thermal cycling is common.

Features & Benefits

Superior Thermal Performance

The exceptional thermal characteristics of this High Temp PI Film Over Silicone Foam Flame Retardant Self Adhesive for Automotive Electronics stem from its carefully engineered multi-layer construction. The polyimide film layer provides excellent thermal conductivity in the through-plane direction while maintaining electrical insulation properties. This unique combination allows for efficient heat dissipation from electronic components while preventing electrical short circuits and interference.

The silicone foam substrate contributes to the material's thermal management capabilities by providing a compliant interface that maintains consistent thermal contact even under vibration and thermal cycling conditions common in automotive environments. This compliance ensures that the thermal interface remains effective throughout the product's operational life, preventing hot spots and thermal runaway conditions that could compromise system reliability.

Enhanced Safety and Compliance

Safety considerations are paramount in automotive electronics applications, and this flame retardant material addresses these concerns through its inherent fire resistance properties. The specialized formulation inhibits flame propagation and reduces smoke generation in the event of thermal incidents, contributing to overall vehicle safety systems. This characteristic is particularly important in modern vehicles where high-power electronics are integrated throughout the vehicle architecture.

The material's compliance with automotive industry standards ensures that manufacturers can integrate this solution into their designs with confidence in meeting regulatory requirements. The flame retardant properties are maintained across the operating temperature range, providing consistent safety performance regardless of environmental conditions.

Installation Efficiency

The self-adhesive backing of this High Temp PI Film Over Silicone Foam Flame Retardant Self Adhesive for Automotive Electronics significantly reduces installation time and complexity compared to traditional thermal interface materials. The adhesive system is specifically formulated to provide immediate tack for positioning while developing full bond strength over time, allowing for repositioning during assembly if necessary.

This ease of installation translates to reduced manufacturing costs and improved production efficiency for automotive electronics manufacturers. The material can be die-cut to precise shapes and dimensions, enabling automated assembly processes and ensuring consistent application across high-volume production runs.

Applications & Use Cases

The versatility of this High Temp PI Film Over Silicone Foam Flame Retardant Self Adhesive for Automotive Electronics makes it suitable for a wide range of automotive electronics applications. In engine control units and powertrain electronics, the material provides critical thermal management for high-power semiconductors and processors that generate significant heat during operation. The high-temperature stability ensures reliable performance even in the harsh environment of the engine compartment where temperatures can fluctuate dramatically.

Battery management systems in electric and hybrid vehicles represent another key application area where this material excels. The combination of thermal management, electrical insulation, and flame retardant properties makes it ideal for use in battery pack assemblies where safety and thermal control are critical for both performance and safety. The material's ability to maintain its properties under thermal cycling conditions ensures long-term reliability in these demanding applications.

Advanced driver assistance systems and infotainment electronics also benefit from the unique properties of this material. As these systems become more sophisticated and process-intensive, effective thermal management becomes essential for maintaining performance and preventing thermal throttling. The material's conformability allows it to be used in compact electronic packages where space constraints require efficient thermal solutions.

Charging infrastructure components, including onboard chargers and DC-DC converters, utilize this material for thermal interface applications where high power densities create significant thermal management challenges. The flame retardant properties provide additional safety margins in these high-energy applications, while the thermal performance ensures efficient heat dissipation to maintain charging rates and component longevity.

Quality Control & Compliance

Manufacturing excellence and consistent quality are fundamental to the production of this High Temp PI Film Over Silicone Foam Flame Retardant Self Adhesive for Automotive Electronics. Comprehensive quality control processes ensure that each batch meets the stringent requirements of automotive electronics applications, where reliability and performance consistency are non-negotiable.

The manufacturing process incorporates advanced process controls and monitoring systems that track key parameters throughout production. This approach ensures that the thermal, electrical, and mechanical properties remain within specification limits, providing customers with consistent performance characteristics across all deliveries. Regular testing protocols verify flame retardant performance, thermal conductivity, and adhesion strength to ensure compliance with automotive industry standards.

Environmental testing protocols simulate the harsh conditions encountered in automotive applications, including temperature cycling, humidity exposure, and vibration testing. These comprehensive evaluations ensure that the material maintains its performance characteristics throughout the expected service life in automotive environments. The testing regimen also includes accelerated aging studies that predict long-term performance and identify any potential degradation mechanisms.

Traceability systems track materials from raw material receipt through final product delivery, enabling rapid response to any quality concerns and ensuring compliance with automotive industry quality management requirements. This comprehensive approach to quality control provides customers with confidence in the reliability and consistency of the product across their production requirements.

Customization & Branding Options

Understanding that automotive electronics applications often require specialized solutions, extensive customization capabilities are available for this High Temp PI Film Over Silicone Foam Flame Retardant Self Adhesive for Automotive Electronics. Custom die-cutting services enable the production of precise shapes and configurations that match specific component layouts and assembly requirements, eliminating waste and ensuring optimal fit and function.

Thickness variations can be tailored to meet specific thermal resistance requirements and accommodate varying gap dimensions in electronic assemblies. The ability to adjust the foam density and compression characteristics allows for optimization of thermal performance while maintaining the necessary compliance for reliable thermal contact. These customization options enable engineers to optimize their thermal management solutions for specific applications and performance requirements.

Private labeling and custom packaging options are available for distributors and OEM customers who require branded solutions for their market channels. Custom packaging can include specific handling instructions, application guidelines, and technical data sheets tailored to the end-user requirements. This flexibility supports various distribution models and helps customers maintain their brand identity while offering high-quality thermal management solutions.

Technical support services include material selection guidance, application engineering support, and performance optimization recommendations. This collaborative approach ensures that customers can fully leverage the capabilities of the material while addressing their specific application challenges and performance objectives.

Packaging & Logistics Support

Efficient packaging and logistics solutions ensure that this High Temp PI Film Over Silicone Foam Flame Retardant Self Adhesive for Automotive Electronics reaches customers in optimal condition while supporting their operational requirements. Protective packaging systems prevent contamination and damage during storage and transportation, maintaining the material's performance characteristics from production through application.

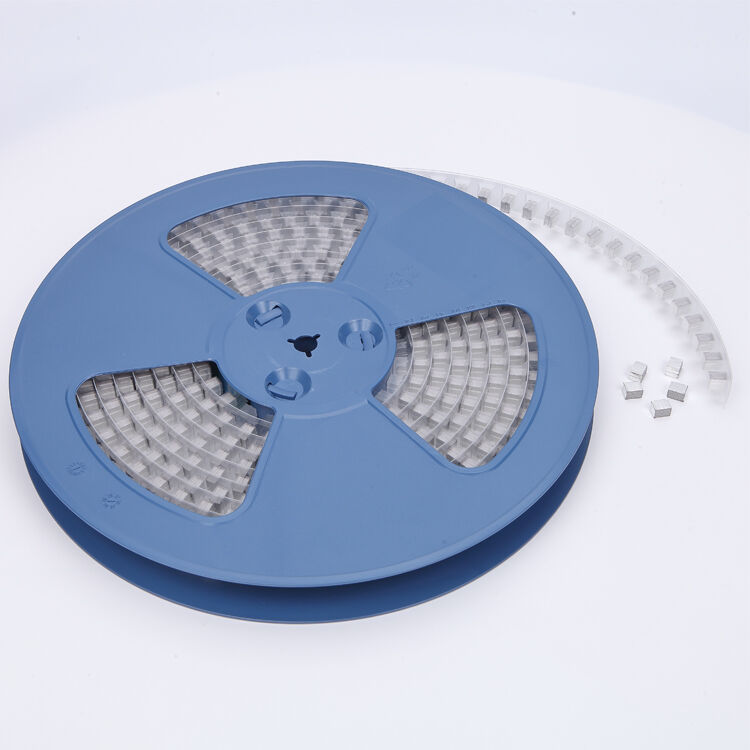

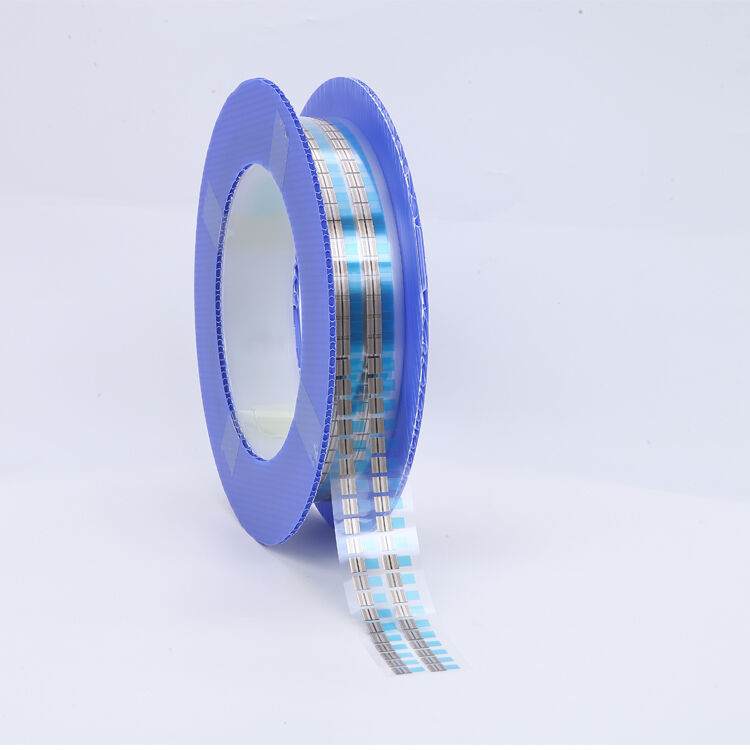

Roll packaging options provide flexibility for high-volume users who require continuous material feed for automated assembly processes. The packaging design accommodates various roll widths and lengths while maintaining proper material protection and handling characteristics. Interleaving papers and protective films prevent adhesive transfer and contamination during unwinding operations.

Sheet packaging formats support customers who require pre-cut sizes or smaller quantities for prototype development and low-volume production. Individual sheet protection and organized packaging facilitate inventory management and material handling in production environments. Custom packaging configurations can be developed to support specific customer requirements and integration with existing material handling systems.

Global logistics support ensures reliable delivery to automotive manufacturing locations worldwide. Established distribution networks and logistics partnerships enable efficient supply chain management while maintaining product quality and availability. Temperature-controlled shipping options are available for applications where environmental conditions during transportation could affect material properties.

Why Choose Us

With over two decades of experience in advanced material development and manufacturing for automotive applications, our company has established itself as a trusted partner for automotive electronics manufacturers worldwide. Our global presence and multi-industry expertise enable us to understand the unique challenges faced by automotive engineers and provide innovative solutions that meet the evolving requirements of the industry.

Our commitment to research and development ensures that products like the High Temp PI Film Over Silicone Foam Flame Retardant Self Adhesive for Automotive Electronics incorporate the latest advances in material science and manufacturing technology. Collaborative relationships with leading automotive OEMs and tier-one suppliers provide valuable insights into emerging trends and requirements, enabling proactive development of solutions that address future market needs.

As a recognized metal packaging manufacturer and custom tin box supplier, our manufacturing capabilities extend beyond thermal management materials to include comprehensive packaging solutions that support automotive electronics applications. This diverse expertise enables us to provide integrated solutions that address multiple aspects of automotive electronics manufacturing and assembly requirements.

Our OEM tin packaging solutions and capabilities as a metal packaging supplier complement our thermal management product portfolio, providing customers with access to comprehensive material and packaging solutions from a single trusted source. This integrated approach simplifies supply chain management while ensuring consistent quality and technical support across all product categories.

Continuous investment in manufacturing technology and quality systems ensures that our products meet the highest standards of performance and reliability. Our ISO-certified facilities and automotive-specific quality management systems provide customers with confidence in our ability to deliver consistent, high-quality products that meet their demanding requirements.

Conclusion

The High Temp PI Film Over Silicone Foam Flame Retardant Self Adhesive for Automotive Electronics represents a significant advancement in thermal management technology for automotive applications. Its unique combination of thermal performance, safety characteristics, and ease of installation makes it an ideal solution for the demanding requirements of modern automotive electronics. The material's ability to maintain consistent performance across wide temperature ranges while providing flame retardant protection addresses the critical needs of automotive manufacturers who must balance performance, safety, and reliability in increasingly complex electronic systems. Through comprehensive quality control, customization capabilities, and global logistics support, this innovative material provides automotive engineers with a reliable foundation for their thermal management requirements, enabling the development of safer, more efficient, and more reliable automotive electronics systems.

Application

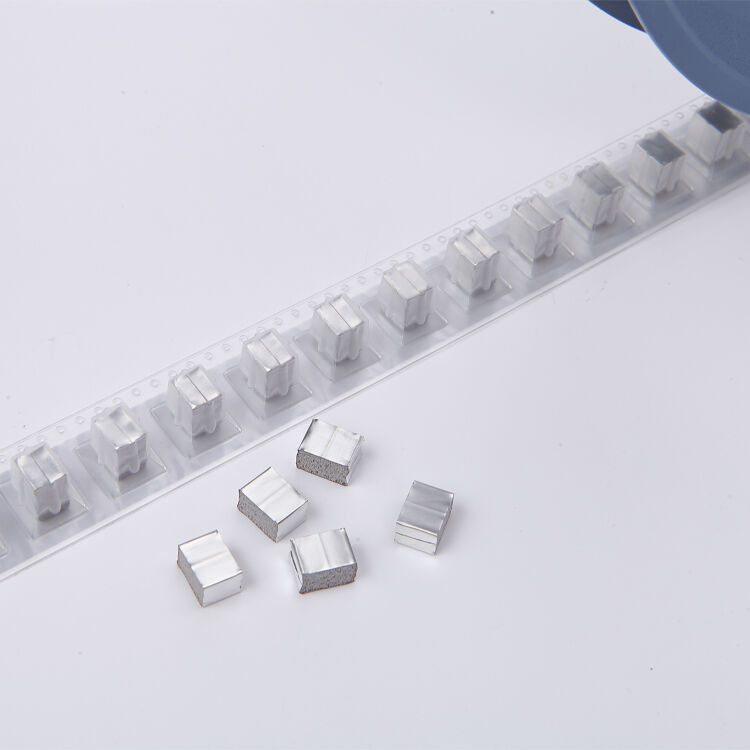

Shielding and grounding around microchip to replace shielding-can frame in smart phones

Shielding and grounding of I/O interface in server/base station or ECU/MCU in automotive

Item |

Typical Value |

Working Resistance |

<0.5Ω |

Adhesion Strength

|

≥1N/3mm |

Core hardness |

<50(ShoreA) |

Compression Range |

20-50%compression of original height |

Compression Set |

≤10%(after 70℃@72 hrs,50% compression ratio) |

High Temperature/Humidity |

No obvious change of elasticity and electric resistance

(85℃/85%RH/72hrs)

|

Therma lShock |

No obvious change of elasticity and electric resistance |

Operation Temperature |

-40~200 degree |

Environment |

Halogen Free,RoHS Compliant |

System certification

Invention Patent

Company Profile

We cater primarily to the consumer electronics, communication networks, and emerging energy vehicle sectors. To back ourcommitment to quality and innovation, we have established a national production base across four strategic locations:

1. A 1,000-square-meter new material formula R&D center in Shenzhen.

2. A 2,000-square-meter innovative grounding wrapping production plant in Dongguan.

3. A 10,000-square-meter conductive shielding tape coating plant in Hunan.

4. A 1,000-square-meter magnetron sputtering continuous gold/tin plating plant in Shandong.

As the only vertically integrated integrator in China offering electroplating, coating, and processing capabilities, we strive to become a leading innovator and provider of core values within the materials industry chain. Our ultimate goal is to be a long-term trusted solution provider and partner for our customers in addressing their challenges.

FAQ

We are based in Guangdong, China, start from 2011,sell to South Asia(10.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Shielding tape,Adhesive tapes,Waterproof and breathable membrane,Customized production,Raw material die-cutting

4. why should you buy from us not from other suppliers?

Shenzhen Johan Material Tech Co., Ltd. was established in 2011, and is an innovative national high-tech enterprise providing

innovative EMC (electromagnetic compatibility) grounding elastomers and customized tape solutions for the electronics indus

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency: USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken: English,Chinese