Introduction

Modern electronics and automotive industries demand sealing solutions that deliver exceptional performance under extreme conditions. High Performance Poron Foam Superior Compression Resistance for Precision Gaskets in Electronics Automotive Applications represents the pinnacle of advanced cellular urethane technology, engineered specifically for critical sealing applications where traditional materials fall short. This specialized foam material combines outstanding compression resistance with superior sealing capabilities, making it an indispensable component for manufacturers seeking reliable protection against environmental contaminants, moisture ingress, and electromagnetic interference.

The evolution of electronic devices toward smaller form factors and higher power densities has created unprecedented challenges for sealing and gasketing materials. Simultaneously, automotive applications continue to push the boundaries of operating temperatures, chemical exposure, and mechanical stress. Our Poron foam technology addresses these demanding requirements through innovative polymer chemistry and precision manufacturing processes that ensure consistent performance across diverse operating conditions.

Product Overview

High Performance Poron Foam Superior Compression Resistance for Precision Gaskets in Electronics Automotive Applications is a closed-cell polyurethane foam material specifically formulated to maintain dimensional stability and sealing effectiveness under sustained compression loads. The unique cellular structure provides excellent recovery properties while maintaining consistent compression set characteristics throughout extended service life. This material represents a significant advancement in foam gasket technology, offering superior performance compared to traditional rubber compounds and standard foam materials.

The foam's microcellular structure creates an optimal balance between compressibility and recovery force, ensuring reliable sealing contact while minimizing stress on delicate electronic components. Advanced polymer formulation delivers exceptional resistance to thermal cycling, chemical exposure, and ultraviolet degradation, making it suitable for both indoor electronics applications and demanding automotive environments. The material exhibits excellent conformability to irregular surfaces while maintaining consistent sealing pressure distribution.

Features & Benefits

Superior Compression Resistance Technology

The cornerstone of High Performance Poron Foam Superior Compression Resistance for Precision Gaskets in Electronics Automotive Applications lies in its exceptional compression resistance characteristics. Unlike conventional foam materials that lose sealing effectiveness under sustained loads, this advanced formulation maintains structural integrity and sealing performance throughout extended compression cycles. The unique polymer chemistry prevents permanent deformation while ensuring consistent gasket thickness and sealing pressure over time.

The material's outstanding compression set resistance ensures long-term reliability in applications where gaskets must maintain sealing effectiveness for extended periods under constant load. This characteristic is particularly valuable in electronics applications where housing assemblies remain compressed for the entire product lifecycle, and in automotive applications where vibration and thermal cycling create additional stress on sealing components.

Enhanced Sealing Performance

Advanced microcellular technology provides superior sealing effectiveness against a wide range of environmental challenges. The foam's closed-cell structure creates an effective barrier against moisture ingress, dust contamination, and chemical penetration while maintaining breathability where required. This dual functionality makes it ideal for electronic enclosures that require pressure equalization while maintaining environmental protection.

The material demonstrates excellent conformability to surface irregularities and manufacturing tolerances, ensuring reliable sealing contact even on less-than-perfect mating surfaces. This characteristic reduces the need for expensive surface finishing operations while improving overall sealing reliability in production applications.

Thermal and Chemical Stability

Extended temperature range capability ensures consistent performance across diverse operating environments. The foam maintains its sealing properties and dimensional stability from low-temperature storage conditions through elevated operating temperatures common in automotive and industrial electronics applications. Superior chemical resistance provides protection against common automotive fluids, cleaning agents, and industrial chemicals without degradation of sealing performance.

Applications & Use Cases

High Performance Poron Foam Superior Compression Resistance for Precision Gaskets in Electronics Automotive Applications serves critical sealing functions across numerous industries and applications. In electronics manufacturing, the material provides essential environmental protection for sensitive components while accommodating the precise dimensional requirements of modern miniaturized devices. Smartphone and tablet manufacturers rely on this foam technology for camera module sealing, speaker enclosure gasketing, and battery compartment protection.

Automotive applications benefit from the material's exceptional durability and chemical resistance in harsh under-hood environments. Electronic control units, sensor housings, and lighting assemblies require reliable sealing solutions that maintain effectiveness despite exposure to temperature extremes, chemical contamination, and mechanical vibration. The foam's ability to maintain compression resistance ensures long-term sealing reliability throughout vehicle service life.

Industrial electronics applications leverage the material's superior electromagnetic interference shielding properties combined with environmental protection capabilities. Control panel assemblies, instrumentation housings, and communication equipment require sealing solutions that provide both EMI attenuation and moisture protection while maintaining access for service and maintenance operations.

Medical device manufacturers utilize High Performance Poron Foam Superior Compression Resistance for Precision Gaskets in Electronics Automotive Applications for critical sealing applications where contamination control and long-term reliability are paramount. The material's biocompatibility and chemical inertness make it suitable for applications involving contact with medical fluids and cleaning agents.

Quality Control & Compliance

Rigorous quality control processes ensure consistent performance characteristics across every production batch of High Performance Poron Foam Superior Compression Resistance for Precision Gaskets in Electronics Automotive Applications. Advanced testing protocols verify compression set resistance, thermal stability, chemical compatibility, and dimensional accuracy according to international standards. Each production lot undergoes comprehensive evaluation to ensure compliance with automotive and electronics industry specifications.

Environmental compliance represents a fundamental aspect of our manufacturing approach, with careful attention to regulatory requirements across global markets. The material formulation excludes harmful substances while maintaining superior performance characteristics, ensuring compatibility with RoHS directives and automotive environmental regulations. Comprehensive documentation supports customer compliance requirements for regulated industries including automotive, medical, and aerospace applications.

Traceability systems maintain detailed records of raw material sources, processing parameters, and performance test results for each production batch. This comprehensive documentation enables rapid response to customer inquiries and supports root cause analysis in the unlikely event of performance issues. Quality management systems ensure continuous improvement through statistical process control and customer feedback integration.

Customization & Branding Options

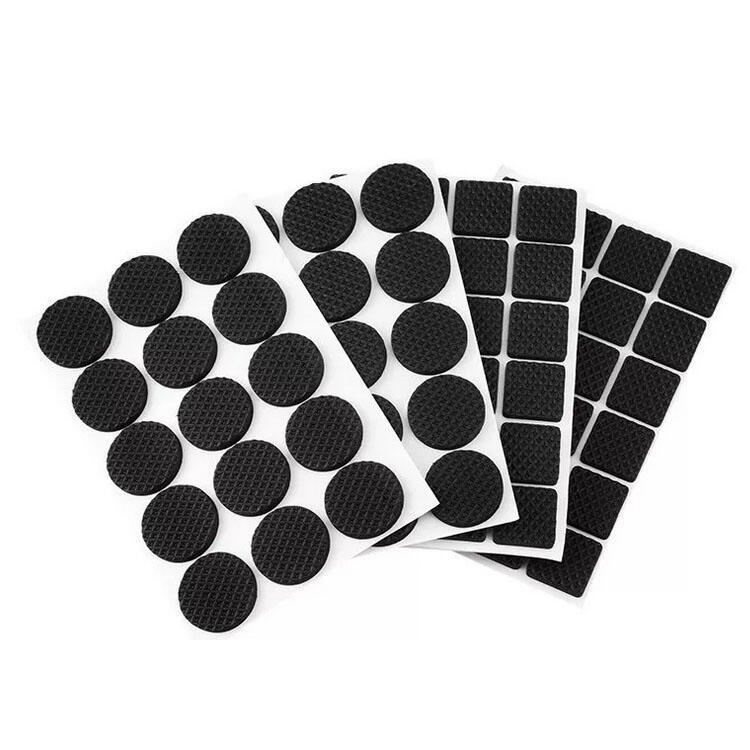

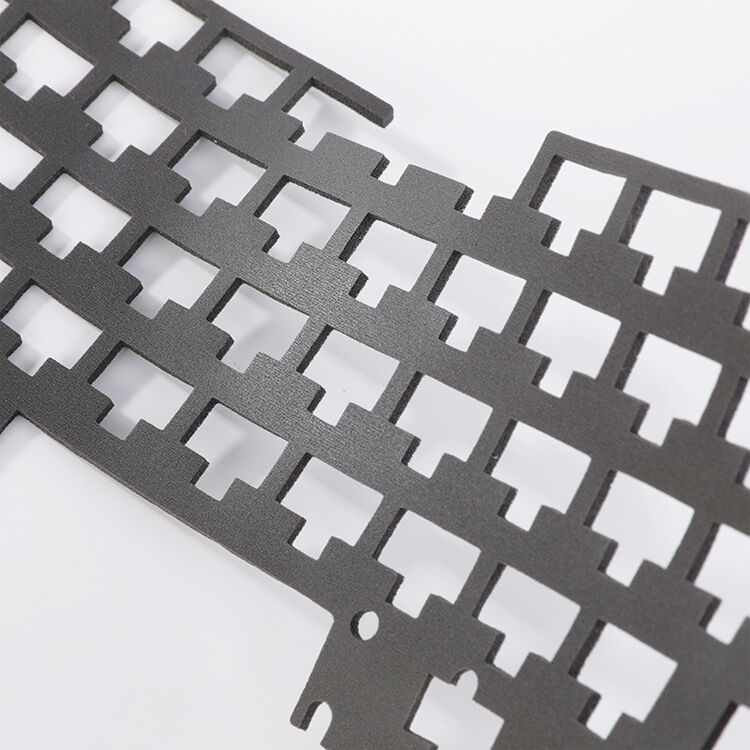

Comprehensive customization capabilities transform High Performance Poron Foam Superior Compression Resistance for Precision Gaskets in Electronics Automotive Applications into precisely engineered solutions for specific applications. Advanced die-cutting technology enables production of complex gasket geometries with tight dimensional tolerances, accommodating intricate electronic housing designs and automotive component configurations. Water-jet cutting capabilities provide smooth, precise edges for applications requiring exceptional sealing surface quality.

Material thickness customization allows optimization of compression characteristics for specific application requirements. Thinner configurations provide space-saving solutions for miniaturized electronics while thicker options deliver enhanced sealing performance for demanding automotive applications. Custom formulations address specific performance requirements such as enhanced chemical resistance, improved thermal stability, or specialized electromagnetic shielding properties.

Adhesive backing options simplify installation and improve gasket retention during assembly operations. Pressure-sensitive adhesive systems provide removable attachment for prototype development and field service applications, while permanent adhesive formulations ensure long-term retention in production assemblies. Custom release liner materials accommodate automated installation equipment and improve manufacturing efficiency.

Packaging & Logistics Support

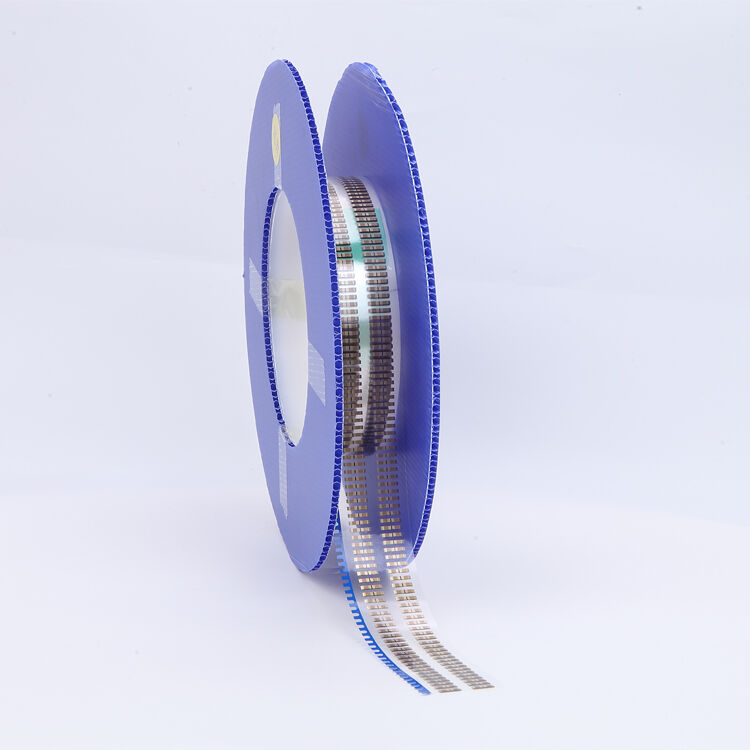

Professional packaging solutions protect High Performance Poron Foam Superior Compression Resistance for Precision Gaskets in Electronics Automotive Applications throughout global distribution while supporting efficient customer operations. Anti-static packaging materials prevent electrostatic discharge damage to sensitive electronic components, while moisture barrier properties maintain material integrity during storage and transportation. Custom packaging configurations accommodate various gasket geometries and quantities while minimizing shipping costs and environmental impact.

Flexible shipping arrangements support both just-in-time manufacturing operations and strategic inventory management approaches. Consolidated shipping options reduce transportation costs for multi-item orders while expedited service capabilities address urgent production requirements. International shipping expertise ensures smooth customs clearance and compliance with import regulations across global markets.

Inventory management support services help customers optimize stock levels while ensuring material availability for production requirements. Vendor-managed inventory programs reduce customer administrative burden while maintaining optimal stock rotation to ensure material freshness. Supply chain integration capabilities support customer ERP systems and automated ordering processes.

Why Choose Us

Our organization brings extensive experience in advanced polymer technology and precision manufacturing to deliver High Performance Poron Foam Superior Compression Resistance for Precision Gaskets in Electronics Automotive Applications that exceeds customer expectations. With established operations serving international markets across electronics, automotive, and industrial sectors, we understand the critical importance of consistent quality and reliable supply chain performance. Our technical expertise spans material science, application engineering, and manufacturing optimization, enabling comprehensive support throughout the product development and production lifecycle.

Strategic partnerships with global electronics manufacturers and automotive suppliers demonstrate our capability to meet demanding performance requirements while maintaining competitive value propositions. Continuous investment in research and development ensures our foam technology remains at the forefront of industry advancement, incorporating emerging requirements for sustainability, performance, and cost effectiveness. Our commitment to customer success extends beyond material supply to include technical consultation, application optimization, and ongoing support services.

As a recognized custom tin box supplier and metal packaging manufacturer, our diversified capabilities enable comprehensive solutions for customers requiring multiple packaging and sealing technologies. This integrated approach provides operational efficiencies and simplified supply chain management while maintaining specialized expertise in each product category. Our status as a trusted OEM tin packaging solutions provider reflects the same commitment to quality and reliability that characterizes our foam gasket technology.

Conclusion

High Performance Poron Foam Superior Compression Resistance for Precision Gaskets in Electronics Automotive Applications represents the convergence of advanced materials science and practical engineering solutions for critical sealing applications. The unique combination of superior compression resistance, exceptional sealing performance, and long-term reliability makes this foam technology essential for manufacturers seeking to optimize product performance while reducing warranty costs and field service requirements. From precision electronics assemblies requiring environmental protection to demanding automotive applications exposed to harsh operating conditions, this advanced foam material delivers consistent performance that enables customer success across diverse markets and applications. The comprehensive support capabilities, customization options, and global supply chain expertise ensure seamless integration into customer operations while maintaining the highest standards of quality and reliability that modern manufacturing demands.

Polyurethane Foam: The Versatile High-Performance Sealing and Cushioning Material

Color |

Density |

Hardness |

Temperature Range |

Certifications |

Black

|

100~480 kg/m³

|

3~50 Shore 00/Shore A |

-20°C to +90°C

|

RoHS, REACH, UL94 HF-1 Flame Retardant Standards |

* Electronics & Appliances: Sealing gaskets for control panels, shock-absorbing pads for sensitive components, battery padding.

* Automotive Industry: Sealing for doors, windows, and lights; sound insulation and vibration damping in interiors.

* Medical Equipment: Cushioning for medical devices, sealing for enclosures, providing comfort and protection.

Invention Patent

System certification

Company Profile

We cater primarily to the consumer electronics, communication networks, and emerging energy vehicle sectors. To back ourcommitment to quality and innovation, we have established a national production base across four strategic locations:

1. A 1,000-square-meter new material formula R&D center in Shenzhen.

2. A 2,000-square-meter innovative grounding wrapping production plant in Dongguan.

3. A 10,000-square-meter conductive shielding tape coating plant in Hunan.

4. A 1,000-square-meter magnetron sputtering continuous gold/tin plating plant in Shandong.

As the only vertically integrated integrator in China offering electroplating, coating, and processing capabilities, we strive to become a leading innovator and provider of core values within the materials industry chain. Our ultimate goal is to be a long-term trusted solution provider and partner for our customers in addressing their challenges.

FAQ

We are based in Guangdong, China, start from 2011,sell to South Asia(10.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Shielding tape,Adhesive tapes,Waterproof and breathable membrane,Customized production,Raw material die-cutting

4. why should you buy from us not from other suppliers?

Shenzhen Johan Material Tech Co., Ltd. was established in 2011, and is an innovative national high-tech enterprise providing

innovative EMC (electromagnetic compatibility) grounding elastomers and customized tape solutions for the electronics indus

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency: USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken: English,Chinese