Introduction

In today's rapidly evolving electronics industry, electromagnetic interference remains one of the most critical challenges facing engineers and manufacturers worldwide. The demand for reliable EMI shielding solutions has never been greater, particularly as electronic devices become increasingly compact and sophisticated. High Performance Conductive Foam Gasket for EMI Shielding With Adhesive ESD Safe Sponge Die Cut Custom Applications represents a breakthrough in electromagnetic compatibility technology, offering superior protection while maintaining the flexibility and customization options that modern manufacturing requires.

This advanced conductive foam gasket solution addresses the growing need for effective electromagnetic interference suppression across multiple industries. As electronic systems become more sensitive and regulatory requirements more stringent, the importance of selecting the right EMI shielding materials cannot be overstated. Our specialized foam gasket technology combines exceptional conductivity with practical application benefits, delivering comprehensive protection against electromagnetic interference while ensuring electrostatic discharge safety throughout various operational environments.

Product Overview

The High Performance Conductive Foam Gasket for EMI Shielding With Adhesive ESD Safe Sponge Die Cut Custom Applications represents a sophisticated engineering solution designed to meet the most demanding electromagnetic compatibility requirements. This innovative gasket system incorporates advanced conductive materials within a flexible foam matrix, creating an effective barrier against electromagnetic interference while maintaining excellent compression recovery properties and long-term durability.

Engineered with precision-formulated conductive compounds, this foam gasket delivers consistent electrical performance across a wide frequency spectrum. The integration of electrostatic discharge safe properties ensures that sensitive electronic components remain protected from both electromagnetic interference and static electricity damage. The adhesive backing system provides secure mounting capabilities, eliminating the need for mechanical fasteners in many applications while simplifying installation procedures and reducing assembly time.

The die-cut customization capability allows for precise shaping to match specific application requirements, ensuring optimal fit and performance in diverse enclosure designs. This flexibility makes the product suitable for both standard and highly specialized applications, accommodating unique geometric constraints while maintaining superior EMI shielding effectiveness throughout the operational lifecycle.

Features & Benefits

Superior Electromagnetic Shielding Performance

The advanced conductive foam construction delivers exceptional electromagnetic interference suppression across multiple frequency ranges, making it ideal for modern electronic applications where signal integrity is paramount. The uniform distribution of conductive particles throughout the foam matrix ensures consistent shielding effectiveness, even under compression or environmental stress conditions. This reliable performance characteristic makes the gasket suitable for critical applications where electromagnetic compatibility compliance is essential.

ESD Safe Protection Technology

Incorporating electrostatic discharge safe properties, this conductive foam gasket provides dual protection against both electromagnetic interference and static electricity buildup. The carefully controlled conductivity levels ensure effective charge dissipation while maintaining the necessary electromagnetic shielding characteristics. This balanced approach protects sensitive electronic components from multiple potential damage sources, extending equipment lifespan and improving overall system reliability.

Adhesive Integration and Installation Efficiency

The integrated adhesive backing system streamlines installation processes while providing secure, long-lasting attachment to various substrate materials. This self-adhesive design eliminates the complexity and cost associated with mechanical fastening systems, reducing assembly time and labor requirements. The adhesive formulation maintains its bonding strength across temperature variations and environmental conditions, ensuring consistent gasket positioning throughout the product lifecycle.

Die Cut Customization Capabilities

Advanced die-cutting technology enables precise customization to match specific application requirements, accommodating complex geometries and tight tolerance specifications. This manufacturing flexibility allows for optimal gasket design that maximizes EMI shielding effectiveness while minimizing material waste. The precision cutting process ensures clean edges and consistent dimensions, contributing to reliable sealing performance and professional appearance in finished assemblies.

Applications & Use Cases

The versatility of High Performance Conductive Foam Gasket for EMI Shielding With Adhesive ESD Safe Sponge Die Cut Custom Applications makes it suitable for an extensive range of industrial and commercial applications. In telecommunications equipment, these gaskets provide essential electromagnetic interference protection for sensitive RF components, ensuring signal clarity and regulatory compliance in base stations, routers, and communication infrastructure equipment. The ESD safe properties make them particularly valuable in environments where static-sensitive components require protection.

Medical device manufacturers rely on these specialized gaskets to meet stringent electromagnetic compatibility requirements while maintaining patient safety standards. The biocompatible foam construction and reliable shielding performance make them ideal for diagnostic equipment, patient monitoring systems, and portable medical devices where electromagnetic interference could compromise device functionality or patient care. The customizable die-cut options allow for integration into compact medical device housings without compromising performance.

Aerospace and defense applications benefit from the exceptional reliability and environmental resistance of these conductive foam gaskets. The ability to maintain consistent EMI shielding performance under extreme temperature variations and mechanical stress makes them suitable for avionics systems, radar equipment, and military communication devices. The lightweight foam construction contributes to overall system weight reduction while providing the electromagnetic protection required for mission-critical applications.

Industrial automation and control systems utilize these gaskets to protect programmable logic controllers, variable frequency drives, and sensor networks from electromagnetic interference that could disrupt manufacturing processes. The die-cut customization capability allows for integration into standard industrial enclosures while providing the flexibility needed for specialized automation equipment designs. The ESD safe properties protect sensitive control circuits from static discharge damage in industrial environments.

Quality Control & Compliance

Our manufacturing processes incorporate comprehensive quality control measures to ensure consistent performance and reliability of every High Performance Conductive Foam Gasket for EMI Shielding With Adhesive ESD Safe Sponge Die Cut Custom Applications. Advanced testing protocols verify electromagnetic shielding effectiveness, adhesive bond strength, and electrostatic discharge properties throughout the production cycle. These rigorous quality assurance procedures guarantee that each gasket meets the exacting standards required for critical EMI shielding applications.

Environmental compliance testing ensures that the materials and manufacturing processes meet international regulatory requirements for electromagnetic compatibility and environmental safety. The foam formulations undergo extensive evaluation for outgassing characteristics, temperature stability, and chemical compatibility to ensure suitability for sensitive electronic applications. Regular calibration of testing equipment and adherence to standardized test methods maintain the accuracy and reliability of quality control measurements.

Traceability systems track material sourcing, manufacturing parameters, and quality test results for each production batch, enabling rapid identification and resolution of any quality concerns. This comprehensive documentation approach supports customer quality requirements and facilitates compliance with industry-specific regulations. The implementation of continuous improvement processes ensures that manufacturing techniques and quality standards evolve to meet changing industry demands and technological advancements.

Customization & Branding Options

The die-cut customization capabilities of High Performance Conductive Foam Gasket for EMI Shielding With Adhesive ESD Safe Sponge Die Cut Custom Applications provide unprecedented flexibility in meeting specific application requirements. Advanced cutting technologies enable the production of complex gasket shapes with precision tolerances, accommodating unique enclosure designs and geometric constraints. This customization capability extends to thickness variations, allowing optimization of compression characteristics for different sealing requirements while maintaining electromagnetic shielding effectiveness.

Color coding options are available to facilitate assembly processes and inventory management, with various foam colors available to match customer specifications or industry standards. Custom packaging solutions can incorporate customer branding elements and specific labeling requirements, supporting brand consistency and professional presentation. These customization options extend to packaging configurations that optimize storage efficiency and handling convenience for different manufacturing environments.

Technical support services assist customers in optimizing gasket designs for specific applications, providing engineering expertise in EMI shielding theory and practical implementation considerations. This collaborative approach ensures that customized solutions deliver optimal performance while maintaining cost-effectiveness and manufacturing efficiency. The availability of prototype quantities enables thorough testing and validation before full-scale production commitments.

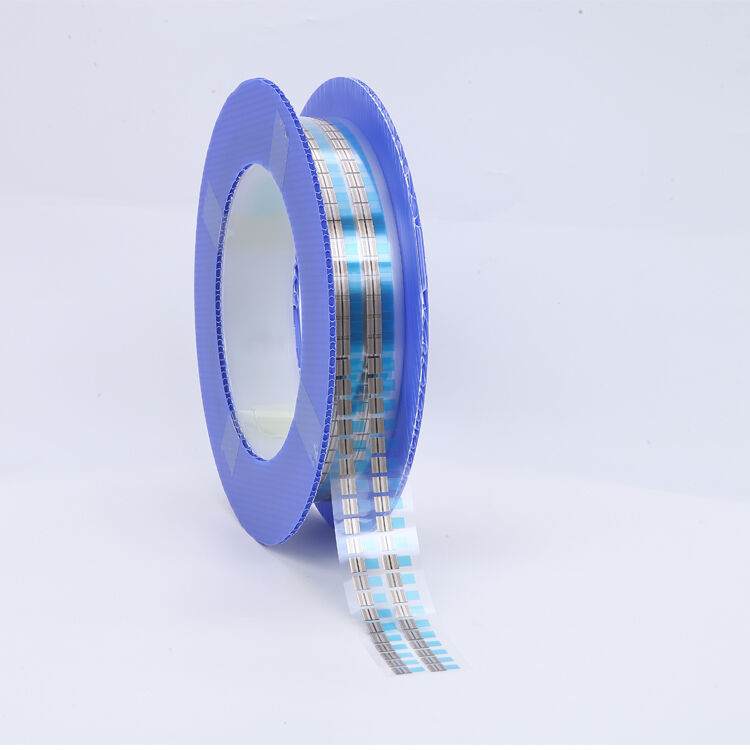

Packaging & Logistics Support

Specialized packaging systems protect the integrity of High Performance Conductive Foam Gasket for EMI Shielding With Adhesive ESD Safe Sponge Die Cut Custom Applications during storage and transportation. Anti-static packaging materials prevent electrostatic discharge damage to the conductive foam while maintaining the adhesive properties of the backing system. Climate-controlled storage recommendations ensure optimal product performance throughout extended storage periods, with packaging designed to minimize compression set and maintain gasket geometry.

Flexible packaging configurations accommodate various order quantities and customer preferences, from individual gasket protection to bulk packaging solutions. The packaging systems include clear identification labeling with part numbers, specifications, and handling instructions to facilitate efficient inventory management and quality control procedures. Moisture barrier properties protect the adhesive backing from environmental degradation, ensuring consistent bonding performance when the gaskets are installed.

Global logistics support capabilities ensure reliable delivery to international markets, with packaging designed to withstand the rigors of international shipping while maintaining product quality. Documentation packages include material certifications, test reports, and handling guidelines to support customer quality requirements and regulatory compliance. The packaging design considers environmental sustainability while maintaining the protection levels required for these specialized EMI shielding components.

Why Choose Us

With extensive experience in electromagnetic compatibility solutions and a proven track record of serving diverse international markets, we have established ourselves as a trusted partner for critical EMI shielding applications. Our commitment to technical excellence and customer satisfaction has resulted in long-term relationships with leading electronics manufacturers, telecommunications companies, and aerospace organizations worldwide. This global collaboration has provided invaluable insights into evolving industry requirements and emerging technological challenges.

Our multi-industry expertise encompasses telecommunications, medical devices, aerospace, industrial automation, and consumer electronics, providing comprehensive understanding of the unique EMI shielding challenges faced by each sector. This broad application knowledge enables us to provide targeted solutions that address specific industry requirements while leveraging best practices from other sectors. The combination of technical expertise and manufacturing capability ensures that High Performance Conductive Foam Gasket for EMI Shielding With Adhesive ESD Safe Sponge Die Cut Custom Applications consistently meets the most demanding performance standards.

Investment in advanced manufacturing technologies and continuous process improvement initiatives maintains our competitive position in the global marketplace. Our quality management systems and technical support capabilities provide customers with confidence in product reliability and performance consistency. The focus on innovation and customer partnership ensures that our EMI shielding solutions evolve to meet the changing demands of modern electronics applications while maintaining the highest standards of quality and reliability.

Conclusion

High Performance Conductive Foam Gasket for EMI Shielding With Adhesive ESD Safe Sponge Die Cut Custom Applications represents a comprehensive solution for the most demanding electromagnetic compatibility challenges in modern electronics manufacturing. The combination of superior EMI shielding performance, ESD safe protection, convenient adhesive installation, and unlimited customization possibilities makes this product an essential component for manufacturers seeking reliable electromagnetic interference protection. The proven performance across diverse applications, from telecommunications infrastructure to medical devices and aerospace systems, demonstrates the versatility and reliability that have made this technology a preferred choice among engineering professionals worldwide. Through continuous innovation and commitment to quality excellence, this advanced gasket solution continues to set new standards for electromagnetic compatibility protection in an increasingly connected world.

Johan ECF (Elastic Conductive Foam)

Technical Data Sheet

|

Updated: May,2021

|

||

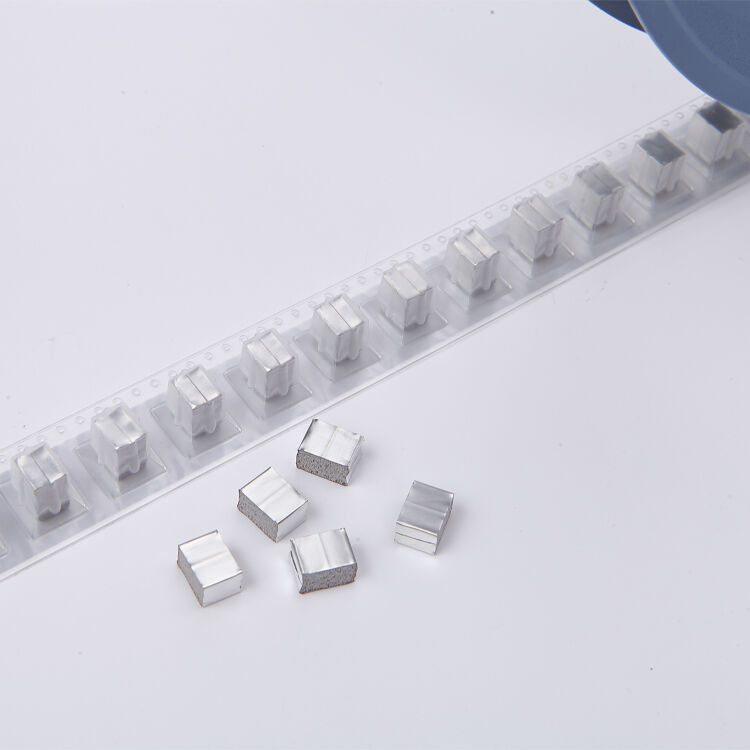

Description

|

This grounding foam is made of high-rebound elastomer base and super thin conductive fabric or film and suitable for high requirement grounding in super thin space. Due to its unique structure, it shows low electrical resistance and stable physical properties even after tough environment test. |

||

Structure

Application

Typical Physical Properties |

The following technical information and data should be considered representative or typical only and should not be used for specification purposes. |

Compression Rate |

0% |

30% |

50% |

70% |

Through-Resistance(Ω) |

0.179 |

0.080 |

0.051 |

0.045 |

Compression Rate |

0% |

30% |

50% |

70% |

Through-Resistance(Ω) |

0.201 |

0.115 |

0.070 |

0.058 |

Other dimension could be customized per demand.

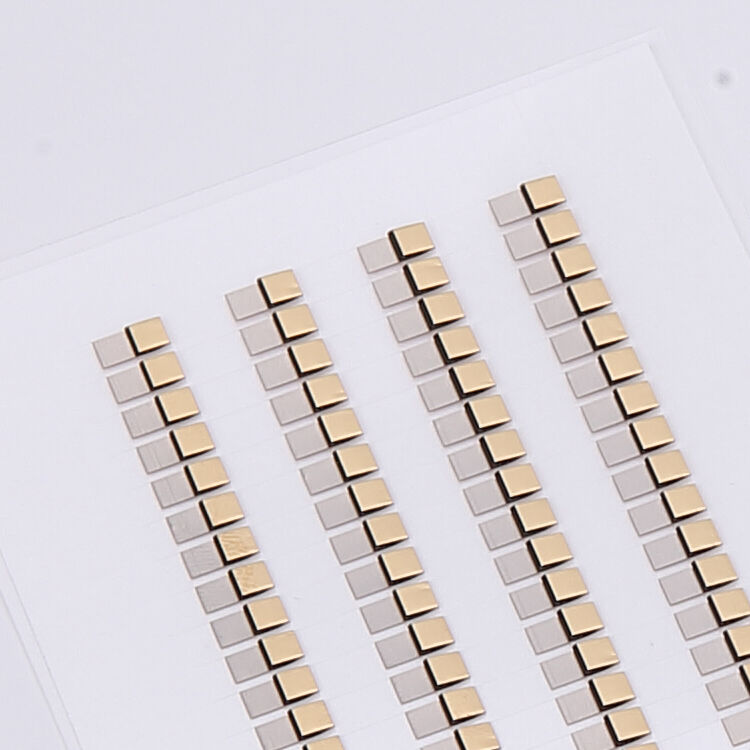

(Fabric/Film with Au-plating work better with high refresh rate display including LCD and provide more stable performance over time)

(Working Height: 0.20mm ECF-SF-05S3 Fabric-Ni-Plating)

(Working Height: 0.30mm ECF-SF-07S3 Fabric-Ni-Plating)

(Working Height: 0.20mm ECF-SF-05S3GP Fabric-Au-Plating )

(Working Height: 0.33mm ECF-SF-07S3GP Fabric-Au-Plating)

Company Profile

We cater primarily to the consumer electronics, communication networks, and emerging energy vehicle sectors. To back ourcommitment to quality and innovation, we have established a national production base across four strategic locations:

1. A 1,000-square-meter new material formula R&D center in Shenzhen.

2. A 2,000-square-meter innovative grounding wrapping production plant in Dongguan.

3. A 10,000-square-meter conductive shielding tape coating plant in Hunan.

4. A 1,000-square-meter magnetron sputtering continuous gold/tin plating plant in Shandong.

As the only vertically integrated integrator in China offering electroplating, coating, and processing capabilities, we strive to become a leading innovator and provider of core values within the materials industry chain. Our ultimate goal is to be a long-term trusted solution provider and partner for our customers in addressing their challenges.

System certification

Invention Patent

FAQ

We are based in Guangdong, China, start from 2011,sell to South Asia(10.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Shielding tape,Adhesive tapes,Waterproof and breathable membrane,Customized production,Raw material die-cutting

4. why should you buy from us not from other suppliers?

Shenzhen Johan Material Tech Co., Ltd. was established in 2011, and is an innovative national high-tech enterprise providing

innovative EMC (electromagnetic compatibility) grounding elastomers and customized tape solutions for the electronics indus

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency: USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken: English,Chinese