Introduction

In today's rapidly evolving electronics landscape, communication devices face increasingly complex challenges from electromagnetic interference, environmental hazards, and stringent performance requirements. The Flexible Conductive Silicone Foam Gasket Superior Shielding Effectiveness Environmental Seal for Communication Device represents a breakthrough solution that addresses these critical needs with precision engineering and advanced material science. This innovative gasket combines the flexibility of silicone foam with superior conductive properties, creating an essential component for modern communication equipment that demands both electromagnetic shielding and environmental protection.

As electronic devices become more sophisticated and operate at higher frequencies, the importance of effective electromagnetic interference shielding cannot be overstated. Traditional sealing solutions often fall short in providing the dual functionality required for communication devices operating in challenging environments. This specialized gasket bridges that gap by offering exceptional shielding performance while maintaining the environmental sealing properties essential for reliable device operation across diverse conditions.

Product Overview

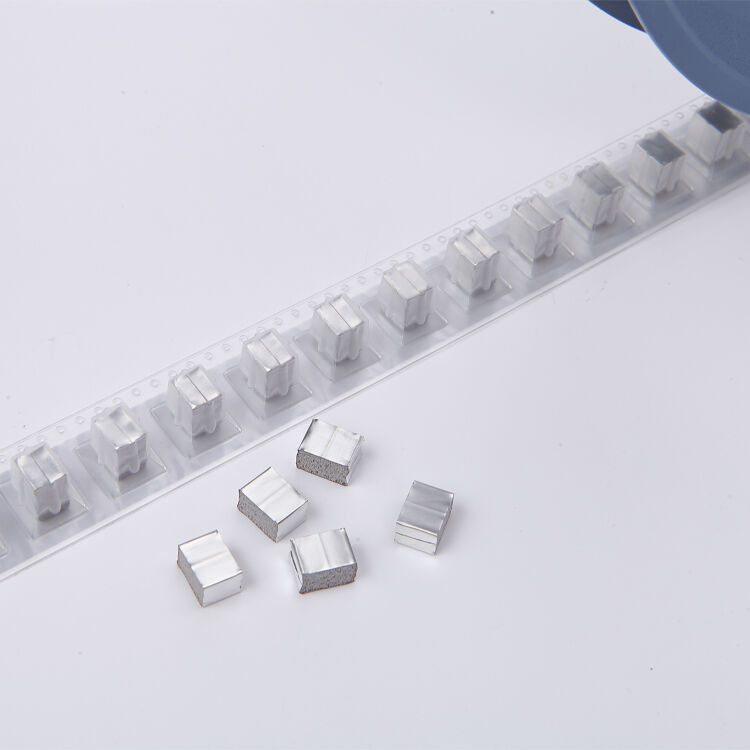

The Flexible Conductive Silicone Foam Gasket Superior Shielding Effectiveness Environmental Seal for Communication Device is engineered using advanced conductive silicone foam technology that delivers outstanding electromagnetic interference suppression capabilities. The gasket's unique composition integrates conductive particles uniformly distributed throughout a flexible silicone matrix, creating consistent electrical conductivity across the entire sealing surface while maintaining the compressive and recovery characteristics essential for effective environmental sealing.

This innovative sealing solution features a closed-cell foam structure that provides excellent compression set resistance and long-term durability. The conductive properties are achieved through carefully selected metallic fillers that ensure reliable electrical continuity without compromising the material's inherent flexibility and resilience. The gasket maintains its sealing integrity across wide temperature ranges and exposure to various environmental conditions, making it an ideal choice for communication devices deployed in demanding applications.

The material exhibits exceptional resistance to moisture, dust, and chemical exposure while providing consistent electromagnetic shielding performance throughout its operational lifetime. Its flexible nature allows for easy installation and accommodation of manufacturing tolerances, ensuring reliable performance even in applications with varying gap dimensions or surface irregularities.

Features & Benefits

Superior Electromagnetic Shielding Performance

The gasket delivers exceptional electromagnetic interference attenuation across a broad frequency spectrum, making it particularly effective for modern communication devices operating across multiple frequency bands. The conductive foam structure creates a continuous electrical path that effectively contains electromagnetic emissions while preventing external interference from compromising device performance. This superior shielding capability ensures compliance with stringent electromagnetic compatibility standards required for communication equipment in various global markets.

Environmental Protection Excellence

Beyond its electromagnetic shielding properties, this Flexible Conductive Silicone Foam Gasket Superior Shielding Effectiveness Environmental Seal for Communication Device provides comprehensive environmental protection. The closed-cell foam structure creates an effective barrier against moisture ingress, dust penetration, and chemical exposure. This dual-function capability eliminates the need for separate shielding and sealing components, simplifying assembly processes and reducing overall component costs while enhancing reliability.

Exceptional Flexibility and Durability

The silicone foam construction offers outstanding compression and recovery characteristics, ensuring consistent sealing performance even after repeated compression cycles. This flexibility allows the gasket to accommodate manufacturing tolerances and thermal expansion while maintaining both electrical continuity and environmental sealing integrity. The material's inherent durability ensures long-term performance stability, reducing maintenance requirements and extending device operational lifespans.

Temperature Stability and Chemical Resistance

Engineered for demanding operating conditions, the gasket maintains its performance characteristics across extreme temperature ranges while resisting degradation from exposure to common environmental contaminants. This stability ensures reliable operation in outdoor installations, industrial environments, and other challenging deployment scenarios where communication devices must function consistently despite environmental stresses.

Applications & Use Cases

The Flexible Conductive Silicone Foam Gasket Superior Shielding Effectiveness Environmental Seal for Communication Device finds extensive application across diverse communication equipment categories. Telecommunications infrastructure equipment, including base stations, repeaters, and signal processing units, benefits significantly from the gasket's ability to provide simultaneous electromagnetic shielding and environmental protection. The material's performance characteristics make it particularly valuable in outdoor installations where equipment must withstand weather exposure while maintaining signal integrity.

Mobile communication devices, including ruggedized handsets, vehicle-mounted systems, and portable communication equipment, leverage the gasket's durability and flexibility to ensure reliable operation across demanding usage scenarios. The material's ability to maintain sealing integrity during repeated opening and closing cycles makes it ideal for equipment requiring periodic access for maintenance or configuration updates.

Aerospace and defense communication systems represent another critical application area where the gasket's superior performance characteristics address stringent requirements for electromagnetic compatibility and environmental protection. The material's proven reliability under extreme conditions makes it suitable for mission-critical applications where communication system failure is not acceptable.

Industrial communication networks, including wireless sensor systems, monitoring equipment, and process control devices, utilize the gasket to ensure consistent operation in harsh industrial environments. The material's chemical resistance and temperature stability make it particularly valuable in manufacturing facilities, chemical processing plants, and other industrial settings where communication equipment faces exposure to challenging environmental conditions.

Quality Control & Compliance

Manufacturing of the Flexible Conductive Silicone Foam Gasket Superior Shielding Effectiveness Environmental Seal for Communication Device follows rigorous quality control protocols that ensure consistent performance characteristics across all production batches. Advanced testing methodologies verify electromagnetic shielding effectiveness, environmental sealing performance, and material durability before products reach customers. These comprehensive quality assurance procedures guarantee that each gasket meets or exceeds specified performance requirements.

The gasket design and manufacturing processes comply with international standards governing electromagnetic compatibility and environmental protection for electronic equipment. Regular testing and certification updates ensure continued compliance with evolving regulatory requirements across global markets. This commitment to standards compliance simplifies the certification process for communication device manufacturers while ensuring end-product regulatory acceptance.

Material traceability systems maintain detailed records of raw material sources, manufacturing parameters, and quality test results for each production batch. This comprehensive documentation supports customer quality requirements and enables rapid response to any performance concerns. The quality management system undergoes regular audits to maintain certification status and ensure continuous improvement in manufacturing processes.

Customization & Branding Options

Understanding that communication device manufacturers have unique requirements, comprehensive customization services are available for the Flexible Conductive Silicone Foam Gasket Superior Shielding Effectiveness Environmental Seal for Communication Device. Custom geometries, including complex shapes, varying thicknesses, and specialized configurations, can be produced to match specific device housing designs and sealing requirements. This flexibility ensures optimal fit and performance for each application while maintaining the material's core performance characteristics.

Material property modifications allow for optimization of specific performance parameters to match particular application requirements. Conductivity levels, compression characteristics, and environmental resistance properties can be adjusted within the material's performance envelope to achieve optimal balance for specific use cases. These customization capabilities enable device manufacturers to specify gaskets that precisely match their performance requirements without compromising on other critical characteristics.

Advanced manufacturing techniques support the production of gaskets with integrated features such as mounting tabs, alignment guides, or specialized surface treatments. These value-added features can simplify assembly processes, improve installation reliability, and reduce overall manufacturing costs for communication device producers. Custom packaging and marking options further support customer-specific requirements for inventory management and quality control.

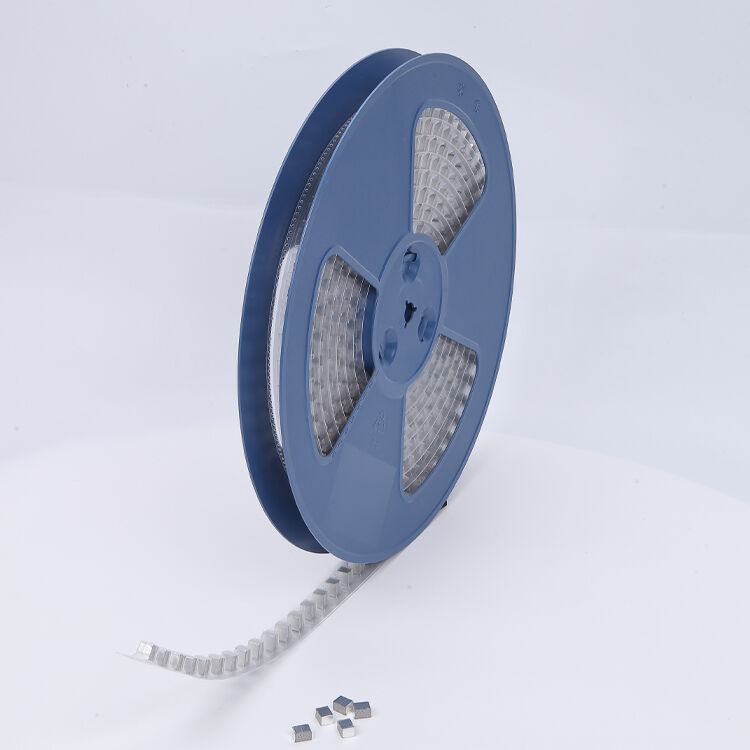

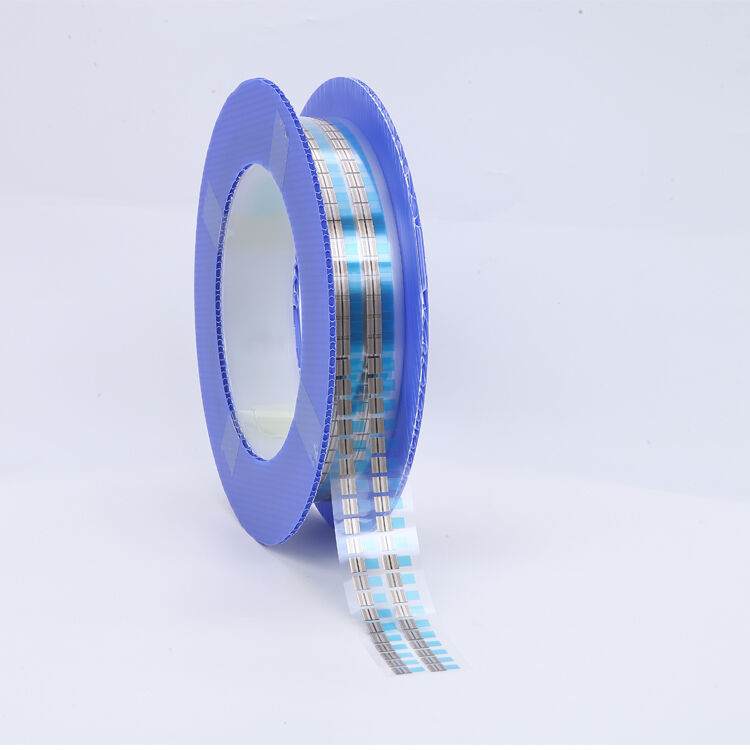

Packaging & Logistics Support

Professional packaging solutions protect gasket integrity during shipping and storage while supporting efficient inventory management for communication device manufacturers. Protective packaging materials prevent compression set and contamination during transit, ensuring that gaskets arrive in optimal condition for immediate use. Standardized packaging configurations support automated handling systems while providing clear product identification and traceability information.

Flexible shipping arrangements accommodate varying order quantities and delivery schedules to support just-in-time manufacturing processes. Careful coordination with logistics partners ensures reliable delivery performance while minimizing transportation costs. Special handling procedures for sensitive applications provide additional protection for gaskets destined for critical communication systems or challenging deployment environments.

Comprehensive documentation accompanies each shipment, including material certificates, performance test reports, and handling recommendations. This documentation supports customer quality control processes and provides essential information for proper gasket installation and application. Digital documentation options streamline record-keeping while supporting sustainability initiatives through reduced paper consumption.

Why Choose Us

With decades of experience serving the global electronics industry, our company has established itself as a trusted supplier of advanced sealing and shielding solutions for communication devices worldwide. Our extensive international market presence enables us to understand and respond to diverse regional requirements while maintaining consistent quality standards across all markets. This global perspective, combined with deep technical expertise, positions us as the preferred partner for communication device manufacturers seeking reliable, high-performance gasket solutions.

Our multi-industry expertise extends beyond communication devices to encompass aerospace, defense, automotive, and industrial applications, providing valuable cross-pollination of innovative technologies and manufacturing best practices. This broad experience base enables us to bring proven solutions from other demanding industries to communication device applications, often resulting in performance improvements and cost optimizations that would not be achievable through narrow specialization.

As a recognized custom packaging solutions provider, we understand the critical importance of protecting sensitive electronic components throughout the supply chain. Our comprehensive approach to product development, manufacturing, and logistics support ensures that customers receive not just a superior gasket product, but a complete solution that addresses their broader operational requirements. This holistic approach has made us the preferred choice for leading communication device manufacturers seeking to optimize their product performance and manufacturing efficiency.

Conclusion

The Flexible Conductive Silicone Foam Gasket Superior Shielding Effectiveness Environmental Seal for Communication Device represents the culmination of advanced material science and precision engineering, delivering a comprehensive solution for the dual challenges of electromagnetic interference control and environmental protection in modern communication systems. Its unique combination of superior shielding performance, exceptional environmental sealing capabilities, and outstanding durability makes it an indispensable component for communication devices operating across diverse and demanding applications. The gasket's proven reliability, comprehensive customization options, and strong quality assurance foundation ensure that communication device manufacturers can confidently specify this solution for their most critical applications, knowing that it will deliver consistent performance throughout extended operational lifespans while supporting their broader objectives for product reliability and market success.

Application

Shielding and grounding around microchip to replace shielding-can frame in smart phones

Shielding and grounding of I/O interface in server/base station or ECU/MCU in automotive

Item |

Typical Value |

Working Resistance |

<0.5Ω |

Adhesion Strength

|

≥1N/3mm |

Core hardness |

<50(ShoreA) |

Compression Range |

20-50%compression of original height |

Compression Set |

≤10%(after 70℃@72 hrs,50% compression ratio) |

High Temperature/Humidity |

No obvious change of elasticity and electric resistance

(85℃/85%RH/72hrs)

|

Therma lShock |

No obvious change of elasticity and electric resistance |

Operation Temperature |

-40~200 degree |

Environment |

Halogen Free,RoHS Compliant |

System certification

Invention Patent

Company Profile

We cater primarily to the consumer electronics, communication networks, and emerging energy vehicle sectors. To back ourcommitment to quality and innovation, we have established a national production base across four strategic locations:

1. A 1,000-square-meter new material formula R&D center in Shenzhen.

2. A 2,000-square-meter innovative grounding wrapping production plant in Dongguan.

3. A 10,000-square-meter conductive shielding tape coating plant in Hunan.

4. A 1,000-square-meter magnetron sputtering continuous gold/tin plating plant in Shandong.

As the only vertically integrated integrator in China offering electroplating, coating, and processing capabilities, we strive to become a leading innovator and provider of core values within the materials industry chain. Our ultimate goal is to be a long-term trusted solution provider and partner for our customers in addressing their challenges.

FAQ

We are based in Guangdong, China, start from 2011,sell to South Asia(10.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Shielding tape,Adhesive tapes,Waterproof and breathable membrane,Customized production,Raw material die-cutting

4. why should you buy from us not from other suppliers?

Shenzhen Johan Material Tech Co., Ltd. was established in 2011, and is an innovative national high-tech enterprise providing

innovative EMC (electromagnetic compatibility) grounding elastomers and customized tape solutions for the electronics indus

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency: USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken: English,Chinese