Introduction

In today's rapidly evolving electronics industry, electromagnetic interference protection has become a critical consideration for manufacturers seeking to maintain product reliability and regulatory compliance. The ESD Shielding Conductive Foam Gasket With Pressure Sensitive Adhesive for EMI Protection Sponge Elastomers Die Cut represents an advanced solution designed to address the complex challenges of electrostatic discharge prevention and electromagnetic compatibility. This specialized gasket combines superior conductivity with exceptional flexibility, making it an indispensable component for protecting sensitive electronic equipment across diverse industrial applications.

Modern electronic devices face increasing vulnerability to electromagnetic interference, which can compromise performance, cause data corruption, and lead to catastrophic system failures. Our conductive foam gasket technology provides a reliable barrier against these threats while maintaining ease of installation and long-term durability. The pressure-sensitive adhesive backing ensures secure mounting without requiring additional fasteners or complex installation procedures, making it an ideal choice for manufacturers prioritizing both protection and operational efficiency.

Product Overview

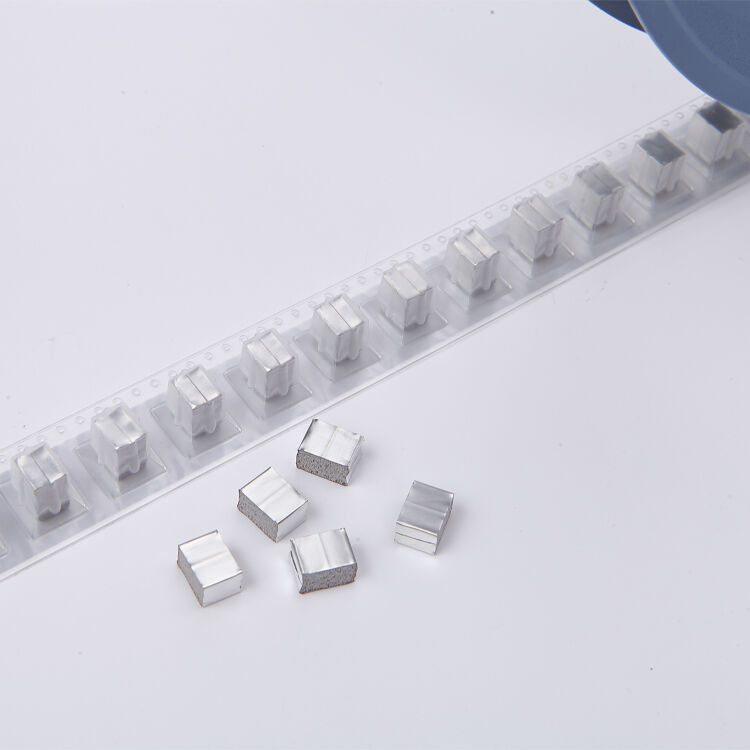

The ESD Shielding Conductive Foam Gasket With Pressure Sensitive Adhesive for EMI Protection Sponge Elastomers Die Cut utilizes advanced materials engineering to deliver exceptional electromagnetic shielding performance. The conductive foam construction incorporates specialized carbon-based compounds that create a continuous electrical pathway, effectively channeling electromagnetic energy away from protected components. This innovative design maintains consistent conductivity across the gasket surface while preserving the flexibility necessary for accommodating varying surface tolerances and mechanical stresses.

The sponge elastomer base provides excellent compression characteristics, allowing the gasket to conform to irregular surfaces and maintain effective sealing under dynamic conditions. The die-cut manufacturing process ensures precise dimensional accuracy and clean edges, eliminating potential stress concentration points that could compromise long-term performance. The pressure-sensitive adhesive system has been specifically formulated to provide immediate bonding strength while accommodating the expansion and contraction cycles commonly encountered in electronic assemblies.

Environmental resistance represents another key aspect of this gasket design, with the materials selected to withstand exposure to temperature variations, humidity, and chemical contaminants typically found in industrial environments. The conductive properties remain stable across extended operating periods, ensuring consistent EMI protection throughout the product lifecycle.

Features & Benefits

Advanced Conductive Technology

The conductive foam gasket incorporates state-of-the-art materials that provide superior electromagnetic shielding effectiveness across broad frequency ranges. The carefully engineered foam structure maintains electrical continuity while offering excellent mechanical properties, including high compression set resistance and durability under repeated compression cycles. This combination ensures reliable performance in applications requiring frequent access or maintenance, where gaskets must repeatedly compress and recover without losing their protective capabilities.

Pressure-Sensitive Adhesive System

The integrated pressure-sensitive adhesive eliminates the need for mechanical fasteners or liquid adhesives during installation, significantly reducing assembly time and labor costs. The adhesive formulation provides immediate tack for positioning accuracy while developing full bond strength over time. This system accommodates thermal cycling without adhesive failure, maintaining secure attachment even when subjected to the temperature variations common in electronic equipment operation.

Die-Cut Precision Manufacturing

Precision die-cutting technology enables the production of gaskets with complex geometries and tight tolerances, ensuring optimal fit for specific application requirements. The clean cutting process eliminates material distortion and maintains consistent cross-sectional density, which directly impacts both sealing effectiveness and electromagnetic shielding performance. Custom shapes and configurations can be produced to match exact design specifications, eliminating the need for field modifications or secondary machining operations.

Applications & Use Cases

The ESD Shielding Conductive Foam Gasket With Pressure Sensitive Adhesive for EMI Protection Sponge Elastomers Die Cut finds extensive application across multiple industries where electromagnetic compatibility and electrostatic discharge protection are essential. Telecommunications equipment manufacturers utilize these gaskets to ensure signal integrity and prevent interference between adjacent circuits, particularly in high-frequency applications where even minimal electromagnetic leakage can cause significant performance degradation.

Medical device applications represent another critical market segment, where patient safety and device reliability depend on effective EMI shielding. The gaskets provide essential protection for sensitive diagnostic equipment, patient monitoring systems, and therapeutic devices that must operate in environments with multiple electromagnetic sources. The biocompatible materials and stable performance characteristics make them suitable for medical applications requiring long-term reliability.

Aerospace and defense applications demand the highest levels of electromagnetic protection due to the critical nature of avionics and communication systems. These gaskets contribute to maintaining signal integrity in radar systems, navigation equipment, and communication devices where electromagnetic interference could compromise mission success or safety. The gaskets' ability to maintain performance under extreme environmental conditions makes them particularly valuable in these demanding applications.

Industrial automation and control systems benefit from the EMI protection provided by these gaskets, ensuring reliable operation of programmable logic controllers, sensor networks, and communication interfaces. The prevention of electromagnetic interference helps maintain process accuracy and prevents costly production disruptions caused by control system malfunctions.

Quality Control & Compliance

Rigorous quality control processes ensure that every ESD Shielding Conductive Foam Gasket With Pressure Sensitive Adhesive for EMI Protection Sponge Elastomers Die Cut meets stringent performance standards and regulatory requirements. Comprehensive material testing validates electrical conductivity, mechanical properties, and environmental resistance before production release. Advanced testing protocols simulate real-world operating conditions to verify long-term performance and reliability.

Electromagnetic compatibility testing confirms shielding effectiveness across relevant frequency ranges, while electrostatic discharge testing validates ESD protection capabilities. Material composition analysis ensures consistency and compliance with international standards for electronic component materials. Environmental testing validates performance under temperature cycling, humidity exposure, and chemical resistance requirements typical of industrial applications.

Traceability systems maintain detailed records of material sources, manufacturing processes, and test results for each production lot, enabling rapid identification and resolution of any quality issues. Statistical process control methods monitor key manufacturing parameters to maintain consistent product quality and performance characteristics across all production runs.

Customization & Branding Options

Comprehensive customization capabilities enable the production of ESD Shielding Conductive Foam Gasket With Pressure Sensitive Adhesive for EMI Protection Sponge Elastomers Die Cut solutions tailored to specific application requirements. Engineering teams collaborate with customers to develop optimal gasket configurations that address unique dimensional constraints, performance specifications, and installation requirements. Advanced modeling techniques predict performance characteristics before physical prototyping, reducing development time and costs.

Material selection options accommodate varying performance requirements, from standard applications to specialized environments requiring enhanced chemical resistance, extended temperature ranges, or specific conductivity levels. Multiple foam densities and adhesive formulations provide flexibility in matching gasket characteristics to application demands while maintaining cost effectiveness.

Manufacturing capabilities support both prototype quantities for product development and full production volumes for commercial applications. Flexible tooling systems enable rapid configuration changes to accommodate design modifications or multiple product variants without significant setup delays or additional costs.

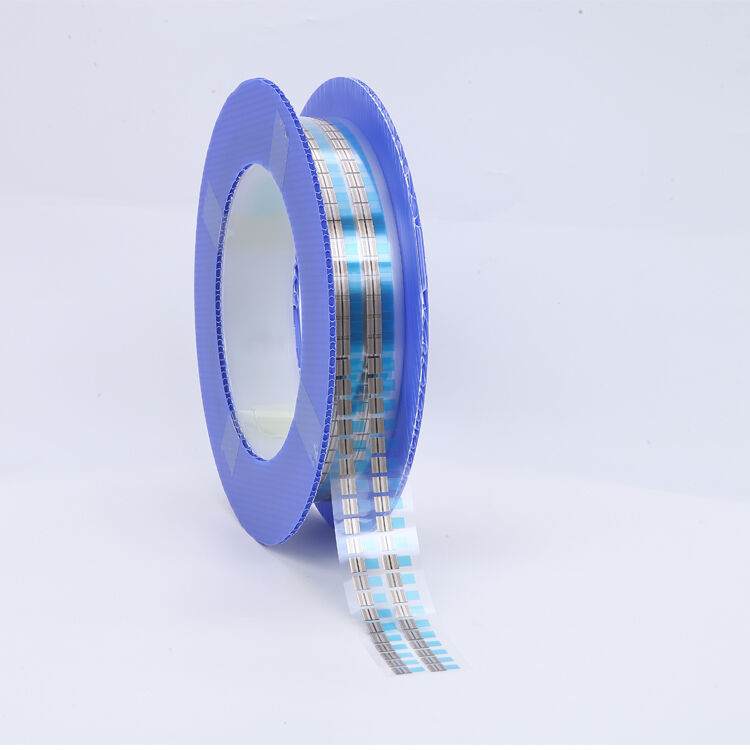

Packaging & Logistics Support

Specialized packaging systems protect the integrity of conductive foam gaskets during storage and transportation while maintaining adhesive performance and material properties. Anti-static packaging materials prevent electrostatic discharge damage during handling, while moisture barrier properties protect against environmental contamination that could affect conductivity or adhesive performance.

Inventory management systems support just-in-time delivery requirements, reducing customer storage costs and ensuring fresh product availability. Flexible packaging configurations accommodate varying order quantities while maintaining material protection and handling efficiency. Clear identification systems enable rapid product verification and inventory tracking throughout the supply chain.

Global distribution networks ensure reliable product availability across international markets, with regional stocking programs reducing delivery times and transportation costs. Comprehensive logistics support includes customs documentation, shipping coordination, and delivery tracking to ensure smooth international transactions and timely product delivery.

Why Choose Us

Our company brings decades of experience in electromagnetic compatibility solutions and conductive materials technology to the development and manufacturing of high-performance gasket products. International market presence across multiple continents ensures reliable supply chain support and local technical assistance for customers worldwide. Recognized quality management systems and certifications validate our commitment to excellence and continuous improvement in product development and manufacturing processes.

Collaborative partnerships with leading electronics manufacturers and system integrators provide valuable insights into emerging market requirements and technology trends. This market intelligence drives continuous product innovation and ensures our solutions remain at the forefront of electromagnetic compatibility technology. Multi-industry expertise spanning telecommunications, medical devices, aerospace, and industrial applications enables comprehensive understanding of diverse performance requirements and regulatory environments.

Technical support services complement our product offerings, providing application engineering assistance, performance optimization recommendations, and troubleshooting support throughout the product lifecycle. This comprehensive approach ensures successful implementation and maximizes the value of our electromagnetic compatibility solutions for customers across diverse industries and applications.

Conclusion

The ESD Shielding Conductive Foam Gasket With Pressure Sensitive Adhesive for EMI Protection Sponge Elastomers Die Cut represents a sophisticated solution for modern electromagnetic compatibility challenges, combining advanced materials technology with precision manufacturing to deliver reliable protection for sensitive electronic systems. The integration of conductive foam technology, pressure-sensitive adhesive convenience, and die-cut precision creates a versatile product that addresses the diverse requirements of contemporary electronics applications while maintaining cost-effectiveness and ease of implementation. Through continuous innovation in materials science and manufacturing processes, this gasket technology continues to evolve to meet the increasingly demanding requirements of next-generation electronic systems across multiple industries.

Product Description

Application

Long term and High reliable grounding between metal case/shielding-can and PCB in game-console

Shielding and grounding around microchip to replace shielding-can frame in smart phones

Shielding and grounding of I/O interface in server/base station or equipment

Conductive Film/Fabric |

Type |

thickness(mm) |

Surface Resistivity |

shielding(10Mhz-3GHz) |

Ni/Cu Polyester Taffeta |

0.08/0.12 |

<0.05ohms |

>70dB |

Coer Foam

|

Type |

Compression Set |

Color |

Flame Retardant(UL 94) |

Urethane/Soft silicone |

5-10% |

Black |

V0/HF-1 |

PSA Tape

|

Type |

Thickness(mm) |

Z Resistivity(ohm) |

Adhesion(N /25mm) |

Conductive double sides adhesive tape |

0.08 |

<0.05 |

>12 |

One year when placed in the warehouse with the temperature between 18-26℃ and humidity

between 45-65%. Follow the first-in-first-out rule

Operation temperature:

-20 to 80℃ for long term and performance may be compromised for excessive high or low temperature.

Company Profile

We cater primarily to the consumer electronics, communication networks, and emerging energy vehicle sectors. To back ourcommitment to quality and innovation, we have established a national production base across four strategic locations:

1. A 1,000-square-meter new material formula R&D center in Shenzhen.

2. A 2,000-square-meter innovative grounding wrapping production plant in Dongguan.

3. A 10,000-square-meter conductive shielding tape coating plant in Hunan.

4. A 1,000-square-meter magnetron sputtering continuous gold/tin plating plant in Shandong.

As the only vertically integrated integrator in China offering electroplating, coating, and processing capabilities, we strive to become a leading innovator and provider of core values within the materials industry chain. Our ultimate goal is to be a long-term trusted solution provider and partner for our customers in addressing their challenges.

Invention Patent

System certification

FAQ

We are based in Guangdong, China, start from 2011,sell to South Asia(10.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Shielding tape,Adhesive tapes,Waterproof and breathable membrane,Customized production,Raw material die-cutting

4. why should you buy from us not from other suppliers?

Shenzhen Johan Material Tech Co., Ltd. was established in 2011, and is an innovative national high-tech enterprise providing

innovative EMC (electromagnetic compatibility) grounding elastomers and customized tape solutions for the electronics indus

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency: USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken: English,Chinese