Introduction

In today's rapidly advancing electronics industry, protecting sensitive components from electromagnetic interference while managing electrostatic discharge has become a critical requirement for manufacturers worldwide. The ESD Conductive Foam Gasket for EMI Shielding With Pressure Sensitive Adhesive Sponge Elastomers Die Cut Custom represents a sophisticated solution that addresses these dual challenges through innovative material engineering and precision manufacturing. This specialized foam gasket combines the superior conductivity required for effective EMI shielding with the electrostatic discharge protection essential for safeguarding delicate electronic assemblies.

Modern electronic devices operate in increasingly complex electromagnetic environments where interference can compromise performance, reliability, and regulatory compliance. Our conductive foam gasket technology provides manufacturers with a versatile, high-performance sealing solution that maintains electromagnetic compatibility while offering the flexibility needed for diverse application requirements. The pressure-sensitive adhesive backing ensures reliable installation and long-term performance across various substrate materials and operating conditions.

Product Overview

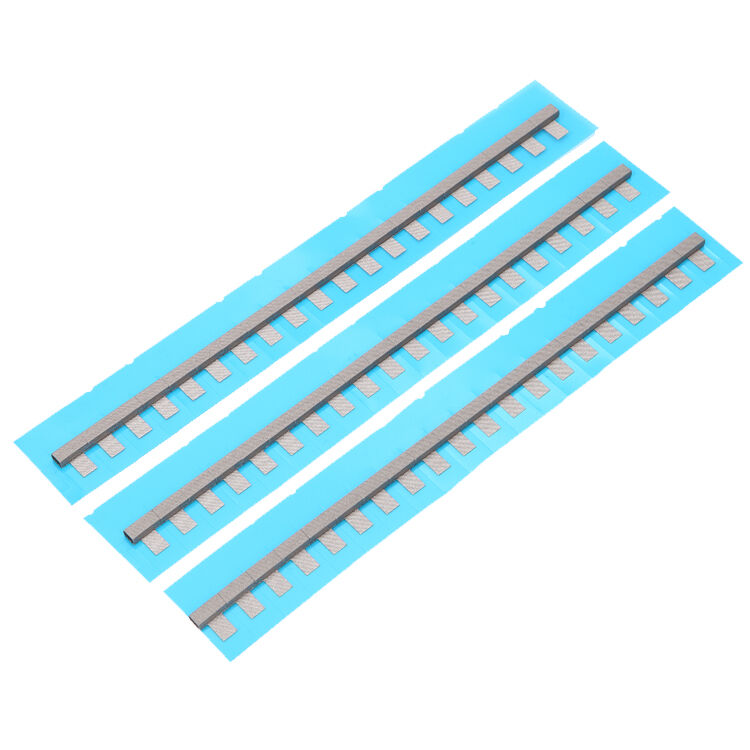

The ESD Conductive Foam Gasket for EMI Shielding With Pressure Sensitive Adhesive Sponge Elastomers Die Cut Custom exemplifies advanced materials science applied to electromagnetic compatibility challenges. This specialized gasket features a carefully engineered foam structure that incorporates conductive particles throughout the elastomeric matrix, creating consistent electrical pathways while maintaining the compressibility and conformability essential for effective sealing applications.

The sponge elastomer construction provides exceptional compression characteristics, allowing the gasket to conform to irregular surfaces and maintain consistent electrical contact across the entire sealing interface. The integrated pressure-sensitive adhesive system eliminates the need for additional fastening methods while ensuring reliable positioning during assembly processes. This combination of electrical conductivity, mechanical flexibility, and installation convenience makes the product particularly suitable for high-volume manufacturing environments where consistency and efficiency are paramount.

Custom die-cutting capabilities enable precise shaping to match specific enclosure designs, housing configurations, and sealing requirements. The manufacturing process accommodates complex geometries, multiple thickness variations, and specialized profiles that conventional gasket solutions cannot achieve. This customization flexibility extends to adhesive selection, foam density options, and conductivity specifications tailored to specific electromagnetic shielding requirements.

Features & Benefits

Advanced Electromagnetic Interference Protection

The conductive foam gasket delivers exceptional EMI shielding effectiveness across a broad frequency spectrum, providing reliable protection against electromagnetic interference that can disrupt sensitive electronic circuits. The uniformly distributed conductive particles create multiple current paths throughout the foam structure, ensuring consistent shielding performance even under compression variations that occur during normal assembly and operation cycles.

Superior electrical conductivity characteristics enable effective grounding of enclosure components while maintaining the mechanical properties essential for sealing applications. The foam structure accommodates surface irregularities and manufacturing tolerances that can compromise the performance of rigid shielding materials, ensuring continuous electrical contact across the entire gasket perimeter.

Comprehensive Electrostatic Discharge Management

Static electricity poses significant risks to modern electronic components, particularly sensitive semiconductors and integrated circuits that can suffer permanent damage from even minor electrostatic events. The ESD Conductive Foam Gasket for EMI Shielding With Pressure Sensitive Adhesive Sponge Elastomers Die Cut Custom incorporates controlled conductivity levels that safely dissipate static charges while preventing the rapid discharge events that can damage sensitive components.

The carefully balanced electrical properties provide a controlled path for static charge dissipation without compromising the electromagnetic shielding effectiveness. This dual functionality eliminates the need for separate ESD and EMI protection systems, simplifying design requirements while reducing component costs and assembly complexity.

Superior Installation and Handling Characteristics

Pressure-sensitive adhesive technology ensures reliable bonding to various substrate materials including metals, plastics, and composite materials commonly used in electronic enclosures. The adhesive system maintains strong initial tack for positioning accuracy while developing full bond strength over time, accommodating the thermal cycling and mechanical stresses encountered in electronic applications.

The sponge elastomer construction provides excellent compression recovery, maintaining seal integrity through repeated compression cycles that occur during maintenance, component replacement, or environmental stress conditions. This resilience extends service life while maintaining consistent electromagnetic shielding performance throughout the product lifecycle.

Applications & Use Cases

Electronic enclosure manufacturers across industries rely on conductive foam gaskets for applications ranging from consumer electronics to aerospace systems where electromagnetic compatibility requirements are increasingly stringent. The versatility of the ESD Conductive Foam Gasket for EMI Shielding With Pressure Sensitive Adhesive Sponge Elastomers Die Cut Custom makes it suitable for handheld devices, automotive electronics, medical equipment, and industrial control systems where reliable EMI shielding and ESD protection are essential.

Telecommunications infrastructure applications benefit from the superior shielding effectiveness and environmental durability that conductive foam gaskets provide. Base station enclosures, network equipment housings, and communication system assemblies require robust electromagnetic protection to ensure signal integrity and regulatory compliance. The custom die-cutting capabilities enable precise fitting around cable entries, connector interfaces, and ventilation openings where standard gasket configurations cannot provide adequate sealing.

Military and aerospace applications demand the highest levels of electromagnetic shielding performance combined with reliability under extreme environmental conditions. The conductive foam gasket technology meets these challenging requirements while accommodating the weight and space constraints typical of aerospace applications. The pressure-sensitive adhesive system simplifies field installation and maintenance procedures, reducing assembly time and improving overall system reliability.

Medical device manufacturers increasingly specify conductive foam gaskets for diagnostic equipment, patient monitoring systems, and therapeutic devices where electromagnetic interference can compromise performance or patient safety. The biocompatible material options and low outgassing characteristics ensure compatibility with medical device requirements while providing the electromagnetic protection necessary for regulatory approval.

Quality Control & Compliance

Manufacturing excellence begins with rigorous material qualification and incoming inspection procedures that verify the electrical, mechanical, and chemical properties of all foam and adhesive components. Advanced testing protocols ensure consistent conductivity levels, compression characteristics, and adhesive performance across production batches, maintaining the reliability that demanding applications require.

Environmental testing validates performance under temperature cycling, humidity exposure, and chemical resistance conditions that electronic assemblies encounter during normal operation and storage. Accelerated aging studies confirm long-term stability of both the conductive properties and mechanical characteristics, ensuring that the ESD Conductive Foam Gasket for EMI Shielding With Pressure Sensitive Adhesive Sponge Elastomers Die Cut Custom maintains its protective effectiveness throughout extended service periods.

Electromagnetic compatibility testing verifies shielding effectiveness across relevant frequency ranges using standardized test methods recognized by international regulatory bodies. This comprehensive validation ensures that products incorporating these gaskets can achieve the electromagnetic compatibility requirements necessary for global market acceptance and regulatory approval.

Quality management systems incorporating international standards ensure consistent manufacturing processes and continuous improvement initiatives that enhance product performance and reliability. Regular audits and process reviews maintain compliance with industry-specific requirements while identifying opportunities for performance enhancements and cost optimization.

Customization & Branding Options

Custom die-cutting services accommodate virtually any gasket geometry required for specific enclosure designs, from simple rectangular shapes to complex profiles incorporating multiple sealing surfaces, cable channels, and component clearances. Advanced cutting technologies enable precise tolerance control and edge quality that ensures consistent fit and performance across high-volume production runs.

Material customization extends beyond basic conductivity requirements to include specialized properties such as flame retardancy, chemical resistance, and temperature performance tailored to specific application environments. Adhesive selection options include removable formulations for temporary applications, high-temperature variants for automotive and aerospace use, and low-outgassing versions for sensitive electronic applications.

Thickness variations and compression characteristics can be optimized for specific sealing requirements, accommodating both fine-pitch applications requiring minimal compression force and heavy-duty installations where robust sealing under high compression is essential. Multi-layer constructions combine different foam densities or conductivity levels within a single gasket to achieve performance characteristics that standard single-layer products cannot provide.

Private labeling and custom packaging options support original equipment manufacturer requirements and distribution channel preferences. Technical documentation customization includes application-specific installation instructions, performance data, and compliance certificates tailored to customer specifications and end-use requirements.

Packaging & Logistics Support

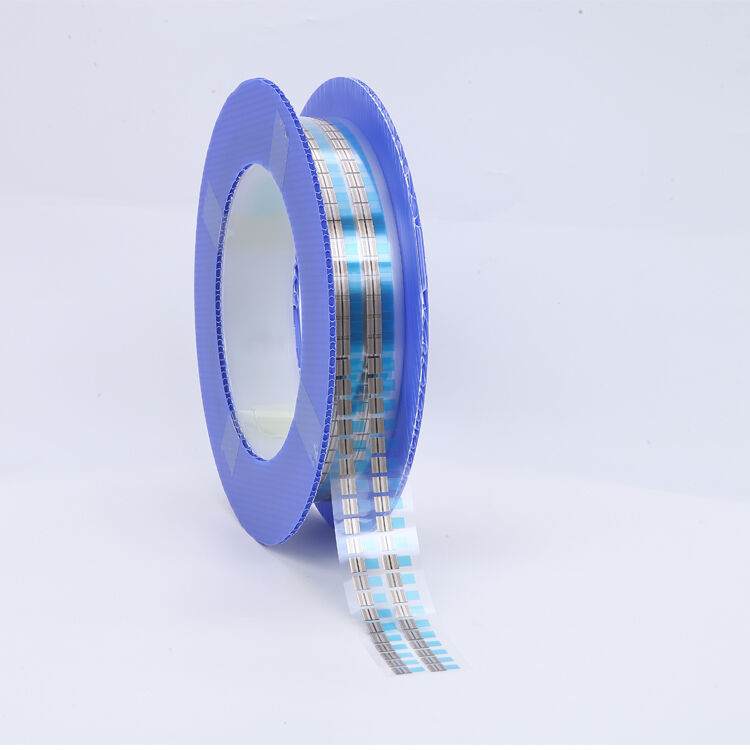

Protective packaging systems preserve gasket integrity during transportation and storage while facilitating efficient handling in manufacturing environments. Anti-static packaging materials prevent electrostatic damage to the conductive foam structure while maintaining the adhesive properties essential for reliable installation. Moisture-barrier packaging protects against environmental exposure that could compromise performance or shelf life.

Inventory management solutions include custom packaging quantities and labeling systems that integrate with customer manufacturing processes and quality tracking requirements. Just-in-time delivery capabilities reduce inventory carrying costs while ensuring material availability for production schedules. Flexible packaging formats accommodate both high-volume automated assembly operations and lower-volume manual installation requirements.

International shipping expertise ensures compliance with transportation regulations for conductive materials while optimizing logistics costs and delivery schedules. Documentation support includes material safety data sheets, compliance certificates, and technical specifications required for customs clearance and customer receiving procedures.

Supply chain reliability incorporates multiple manufacturing locations and strategic inventory positioning to minimize disruption risks and ensure consistent material availability for time-critical applications. Quality assurance extends through the entire distribution network to maintain product integrity from manufacturing to end-user installation.

Why Choose Us

Our extensive experience in conductive materials engineering and electromagnetic compatibility solutions spans multiple decades of collaboration with leading electronics manufacturers worldwide. This deep industry knowledge enables us to provide technical guidance and application support that goes beyond basic product supply, helping customers optimize their electromagnetic shielding solutions for specific performance requirements and manufacturing processes.

Global manufacturing capabilities and quality systems ensure consistent product availability and performance regardless of geographic location or order volume. Our international presence facilitates local support and technical assistance while maintaining the quality standards and material consistency that demanding applications require. This global reach positions us as a reliable metal packaging manufacturer and custom tin box supplier capable of supporting multinational customer operations and supply chain requirements.

Advanced materials research and development capabilities enable continuous improvement in conductive foam technology, adhesive systems, and manufacturing processes. Our technical team collaborates closely with customers to develop specialized solutions for emerging applications and evolving electromagnetic compatibility requirements. This innovation focus ensures that our products remain at the forefront of industry performance standards.

Comprehensive technical support includes electromagnetic compatibility consulting, material selection guidance, and application engineering services that help customers achieve optimal shielding performance while minimizing design complexity and manufacturing costs. Our expertise in OEM tin packaging solutions and sustainable packaging alternatives provides customers with environmentally responsible options without compromising performance requirements.

Conclusion

The ESD Conductive Foam Gasket for EMI Shielding With Pressure Sensitive Adhesive Sponge Elastomers Die Cut Custom represents the convergence of advanced materials science, precision manufacturing, and application-specific engineering that modern electronics applications demand. This sophisticated solution addresses the dual challenges of electromagnetic interference protection and electrostatic discharge management through innovative foam technology and reliable adhesive systems that ensure long-term performance across diverse operating environments.

The combination of superior electrical properties, mechanical flexibility, and installation convenience makes this conductive foam gasket an ideal choice for manufacturers seeking to optimize their electromagnetic compatibility solutions while reducing assembly complexity and component costs. Custom die-cutting capabilities and material customization options provide the flexibility necessary to address unique application requirements and evolving industry standards. As electronics continue to advance in complexity and performance requirements, reliable electromagnetic shielding solutions become increasingly critical for ensuring product reliability, regulatory compliance, and customer satisfaction.

Product Description

Application

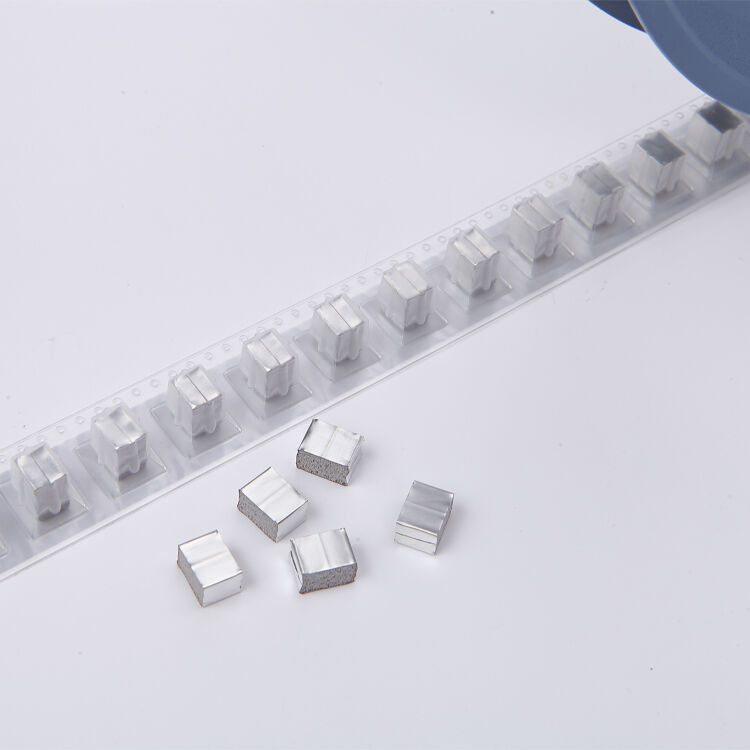

Long term and High reliable grounding between metal case/shielding-can and PCB in game-console

Shielding and grounding around microchip to replace shielding-can frame in smart phones

Shielding and grounding of I/O interface in server/base station or equipment

Conductive Film/Fabric |

Type |

thickness(mm) |

Surface Resistivity |

shielding(10Mhz-3GHz) |

Ni/Cu Polyester Taffeta |

0.08/0.12 |

<0.05ohms |

>70dB |

Coer Foam

|

Type |

Compression Set |

Color |

Flame Retardant(UL 94) |

Urethane/Soft silicone |

5-10% |

Black |

V0/HF-1 |

PSA Tape

|

Type |

Thickness(mm) |

Z Resistivity(ohm) |

Adhesion(N /25mm) |

Conductive double sides adhesive tape |

0.08 |

<0.05 |

>12 |

One year when placed in the warehouse with the temperature between 18-26℃ and humidity

between 45-65%. Follow the first-in-first-out rule

Operation temperature:

-20 to 80℃ for long term and performance may be compromised for excessive high or low temperature.

Company Profile

We cater primarily to the consumer electronics, communication networks, and emerging energy vehicle sectors. To back ourcommitment to quality and innovation, we have established a national production base across four strategic locations:

1. A 1,000-square-meter new material formula R&D center in Shenzhen.

2. A 2,000-square-meter innovative grounding wrapping production plant in Dongguan.

3. A 10,000-square-meter conductive shielding tape coating plant in Hunan.

4. A 1,000-square-meter magnetron sputtering continuous gold/tin plating plant in Shandong.

As the only vertically integrated integrator in China offering electroplating, coating, and processing capabilities, we strive to become a leading innovator and provider of core values within the materials industry chain. Our ultimate goal is to be a long-term trusted solution provider and partner for our customers in addressing their challenges.

Invention Patent

System certification

FAQ

We are based in Guangdong, China, start from 2011,sell to South Asia(10.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Shielding tape,Adhesive tapes,Waterproof and breathable membrane,Customized production,Raw material die-cutting

4. why should you buy from us not from other suppliers?

Shenzhen Johan Material Tech Co., Ltd. was established in 2011, and is an innovative national high-tech enterprise providing

innovative EMC (electromagnetic compatibility) grounding elastomers and customized tape solutions for the electronics indus

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency: USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken: English,Chinese