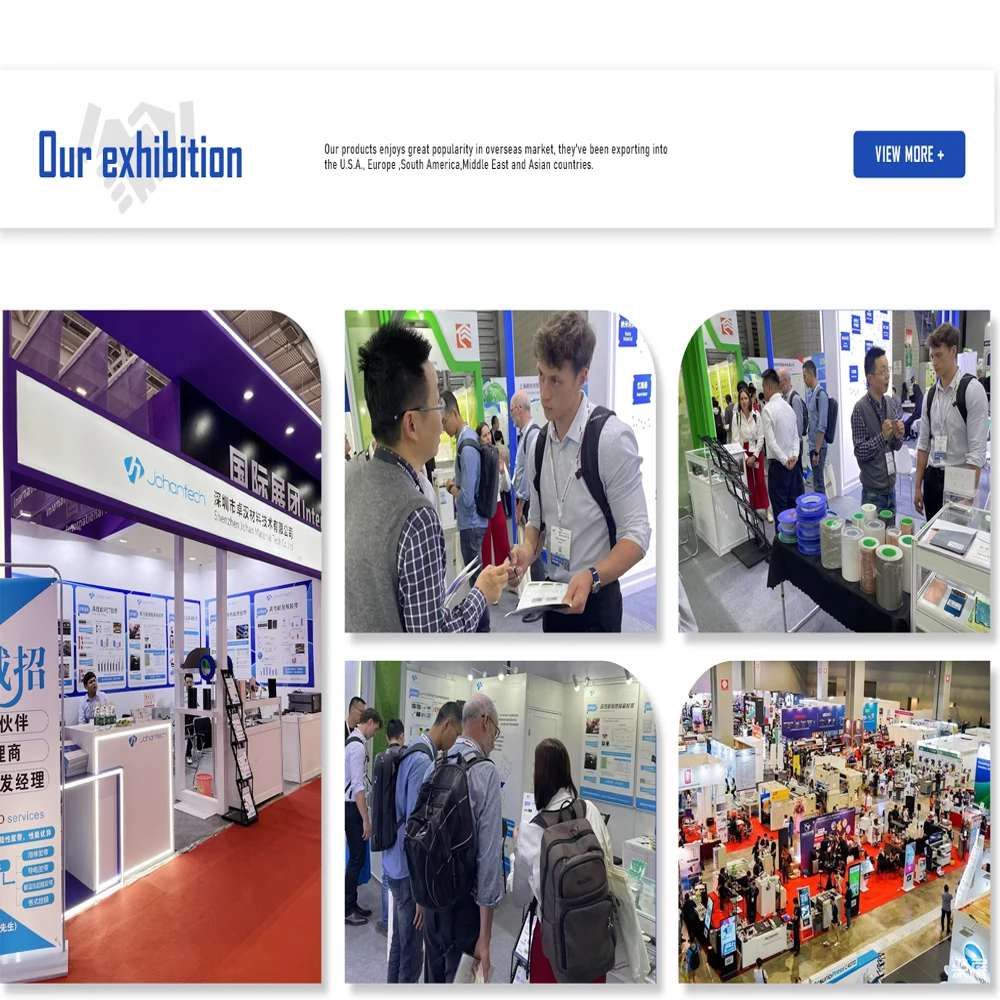

Our company actively pursues global market expansion through strategic participation in premier international exhibitions including CES and Electronics China. We are aggressively penetrating diverse sectors such as consumer electronics, new energy vehicles, communication equipment, and emerging fields including AI and IoT. Having successfully commenced deliveries in these new domains, we maintain strong momentum in continuous exploration of additional overseas markets. Our dynamic approach demonstrates unwavering commitment to global business development and technological innovation.

Quick Links