Introduction

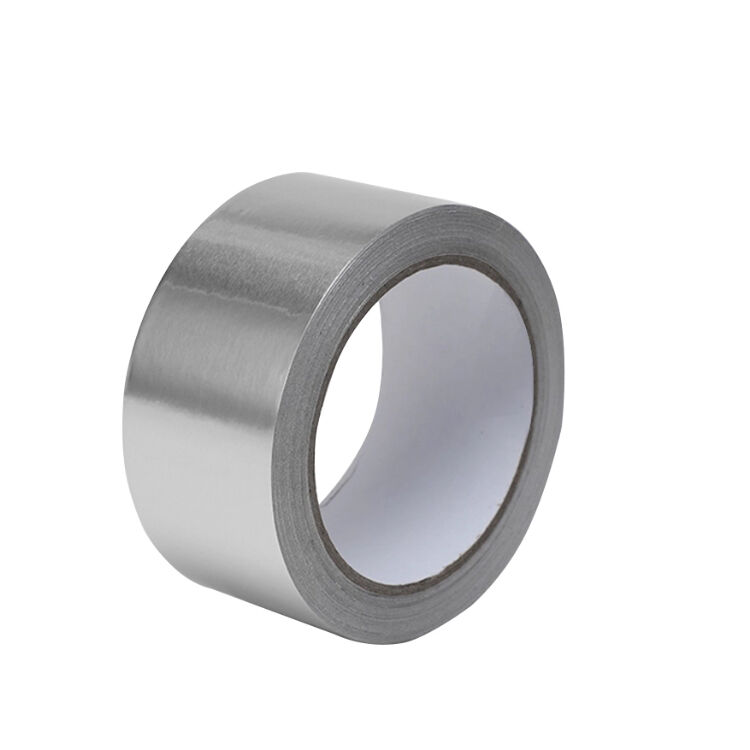

In today's rapidly evolving technological landscape, the demand for reliable electromagnetic interference shielding solutions has reached unprecedented levels. Electronics manufacturers, telecommunications companies, and industrial equipment producers worldwide require advanced materials that can effectively block unwanted electromagnetic signals while providing superior electrical insulation and heat resistance. The Conductive Aluminum Foil Tape for Electromagnetic Interference Shielding Electrical Insulation and Heat Resistant represents a cutting-edge solution engineered to meet these critical requirements across diverse industrial applications.

This specialized adhesive tape combines the inherent conductivity properties of aluminum with advanced polymer backing technology, creating a versatile protective barrier that safeguards sensitive electronic components from electromagnetic interference while maintaining exceptional thermal stability. As global industries continue to miniaturize electronic devices and increase operating frequencies, the importance of effective EMI shielding materials has become paramount for ensuring reliable performance and regulatory compliance.

Product Overview

The Conductive Aluminum Foil Tape for Electromagnetic Interference Shielding Electrical Insulation and Heat Resistant is manufactured using premium-grade aluminum foil laminated with high-performance conductive adhesive systems. This innovative construction methodology ensures optimal electromagnetic shielding effectiveness while providing excellent adhesion characteristics across various substrate materials including metals, plastics, and composite surfaces.

The tape's multi-layered architecture incorporates specialized conductive pathways that facilitate seamless electrical continuity, making it an ideal choice for creating comprehensive EMI shielding enclosures. The aluminum substrate delivers exceptional malleability, allowing for easy application around complex geometries and tight corners without compromising the integrity of the conductive layer. Furthermore, the heat-resistant properties enable reliable performance in elevated temperature environments commonly encountered in power electronics and automotive applications.

Unlike conventional shielding materials that may degrade over time or lose effectiveness under thermal stress, this advanced foil tape maintains its protective characteristics throughout extended operational periods. The carefully engineered adhesive formulation ensures long-term bonding strength while remaining removable when necessary for maintenance or reconfiguration purposes.

Features & Benefits

Superior Electromagnetic Shielding Performance

The primary advantage of this Conductive Aluminum Foil Tape for Electromagnetic Interference Shielding Electrical Insulation and Heat Resistant lies in its exceptional electromagnetic shielding effectiveness across a broad frequency spectrum. The aluminum substrate provides natural conductivity properties that create an effective Faraday cage when properly applied, significantly attenuating both electric and magnetic field components of electromagnetic interference.

The tape's conductive adhesive system ensures complete electrical continuity between overlapping sections, eliminating potential gaps that could compromise shielding performance. This seamless integration capability makes it particularly valuable for creating continuous shielding barriers around sensitive electronic assemblies, cable harnesses, and enclosure seams where traditional shielding methods may prove inadequate.

Enhanced Thermal Management Properties

Beyond its electromagnetic shielding capabilities, this specialized tape offers remarkable heat resistance characteristics that enable reliable operation in challenging thermal environments. The aluminum foil substrate possesses excellent thermal conductivity properties, facilitating efficient heat dissipation from electronic components while maintaining protective barrier integrity.

The heat-resistant adhesive formulation remains stable across wide temperature ranges, preventing adhesive degradation or bond failure that could compromise both mechanical attachment and electrical continuity. This thermal stability makes the tape particularly suitable for applications in automotive electronics, power supplies, and industrial control systems where elevated operating temperatures are common.

Versatile Application Flexibility

The inherent flexibility and conformability of the Conductive Aluminum Foil Tape for Electromagnetic Interference Shielding Electrical Insulation and Heat Resistant enable seamless application across irregular surfaces and complex three-dimensional geometries. This adaptability proves invaluable in modern electronic design where space constraints and unconventional form factors require creative shielding solutions.

The tape can be easily cut, shaped, and formed to accommodate specific application requirements without compromising its protective properties. This versatility extends to various installation methods, including hand application for prototype development and automated dispensing systems for high-volume manufacturing environments.

Applications & Use Cases

The versatility of this Conductive Aluminum Foil Tape for Electromagnetic Interference Shielding Electrical Insulation and Heat Resistant makes it invaluable across numerous industrial sectors and applications. In the telecommunications industry, the tape serves as a critical component for protecting sensitive RF circuits, antenna assemblies, and signal processing equipment from unwanted electromagnetic interference that could degrade signal quality or cause operational failures.

Automotive electronics manufacturers rely on this specialized shielding tape to protect engine control modules, infotainment systems, and advanced driver assistance systems from the harsh electromagnetic environment present in modern vehicles. The tape's heat resistance properties prove particularly beneficial in under-hood applications where elevated temperatures and thermal cycling are prevalent.

Consumer electronics manufacturers utilize the tape for creating electromagnetic compatibility solutions in smartphones, tablets, laptops, and gaming devices. The tape's thin profile and excellent conformability allow for integration into compact device architectures without significantly impacting overall dimensions or weight considerations.

Industrial automation and control systems benefit from the tape's dual functionality of electromagnetic shielding and electrical insulation. The material effectively protects sensitive control circuits from interference generated by high-power motor drives, switching power supplies, and other electromagnetic noise sources commonly found in industrial environments.

Medical device manufacturers incorporate this shielding tape into critical healthcare equipment where electromagnetic interference could potentially compromise patient safety or diagnostic accuracy. The tape's reliable performance characteristics ensure consistent protection throughout the demanding operational requirements of medical environments.

Quality Control & Compliance

Manufacturing excellence and consistent quality represent fundamental commitments in the production of this Conductive Aluminum Foil Tape for Electromagnetic Interference Shielding Electrical Insulation and Heat Resistant. Comprehensive quality control protocols encompass every stage of the manufacturing process, from raw material inspection through final product validation and packaging.

Advanced testing methodologies verify the electromagnetic shielding effectiveness, adhesive performance, and thermal stability characteristics of each production batch. These rigorous evaluation procedures ensure that every roll of tape meets or exceeds specified performance parameters before shipment to customers worldwide.

The manufacturing facility maintains strict adherence to international quality standards and regulatory requirements applicable to electronic materials and adhesive products. Regular third-party audits and certification renewals demonstrate ongoing commitment to quality excellence and customer satisfaction.

Environmental considerations play an increasingly important role in modern manufacturing practices. The production processes incorporate sustainable practices and waste reduction initiatives while maintaining the highest quality standards. Material sourcing emphasizes suppliers who demonstrate environmental responsibility and ethical business practices.

Customization & Branding Options

Recognizing the diverse requirements of global customers, comprehensive customization capabilities are available for the Conductive Aluminum Foil Tape for Electromagnetic Interference Shielding Electrical Insulation and Heat Resistant. Width specifications can be tailored to match specific application requirements, enabling optimal material utilization and installation efficiency for various project scales.

Length configurations accommodate both small-scale prototype development and large-volume production requirements. Custom packaging options include specialized core materials, protective wrapping, and identification labeling systems that integrate seamlessly with customer inventory management and production planning systems.

Private labeling and branding services enable distributors and system integrators to offer the product under their own brand identity while maintaining the underlying quality and performance characteristics. This flexibility supports various business models and market positioning strategies across different geographical regions and industry segments.

Technical documentation customization includes application guides, installation instructions, and compliance certificates tailored to specific market requirements and regulatory environments. These comprehensive support materials enhance customer confidence and facilitate successful product implementation across diverse applications.

Packaging & Logistics Support

Sophisticated packaging systems protect the integrity of this Conductive Aluminum Foil Tape for Electromagnetic Interference Shielding Electrical Insulation and Heat Resistant throughout global distribution networks. Moisture-resistant barrier materials and cushioning systems ensure that products arrive in optimal condition regardless of shipping duration or environmental conditions encountered during transit.

Standardized packaging dimensions optimize shipping efficiency while minimizing transportation costs for customers worldwide. Careful attention to packaging design ensures easy handling and storage in various warehouse environments, from climate-controlled facilities to more challenging industrial storage conditions.

Comprehensive labeling systems provide clear product identification, handling instructions, and traceability information that supports customer inventory management and quality control requirements. These detailed markings facilitate efficient receiving, storage, and distribution processes for importers and distributors.

Flexible shipping arrangements accommodate various customer preferences and logistical requirements. Whether supporting just-in-time manufacturing schedules or building strategic inventory reserves, the logistics infrastructure adapts to meet diverse customer needs while maintaining consistent delivery reliability.

Why Choose Us

With extensive experience serving global markets across multiple industries, our organization has established a reputation for delivering high-quality electromagnetic shielding solutions that meet the demanding requirements of modern electronic applications. This Conductive Aluminum Foil Tape for Electromagnetic Interference Shielding Electrical Insulation and Heat Resistant represents the culmination of years of research, development, and manufacturing expertise focused on creating superior EMI shielding materials.

Our commitment to innovation and continuous improvement ensures that customers receive products incorporating the latest advancements in materials science and manufacturing technology. Regular collaboration with leading electronics manufacturers and research institutions keeps our product development efforts aligned with emerging industry trends and future requirements.

As a trusted metal packaging manufacturer and supplier, we understand the critical importance of material reliability and consistency in electronic applications. Our comprehensive quality management systems and advanced manufacturing capabilities enable us to deliver products that meet the exacting standards required for mission-critical applications across diverse industries.

The global reach of our operations provides customers with reliable access to high-quality electromagnetic shielding solutions regardless of their geographical location. Strategic partnerships with distributors and technical representatives ensure local support capabilities that complement our centralized manufacturing excellence.

Conclusion

The Conductive Aluminum Foil Tape for Electromagnetic Interference Shielding Electrical Insulation and Heat Resistant represents an advanced solution for modern electromagnetic compatibility challenges faced by electronics manufacturers worldwide. Its unique combination of superior shielding effectiveness, thermal stability, and application versatility makes it an essential component for protecting sensitive electronic systems across diverse industrial applications.

From telecommunications infrastructure to automotive electronics, medical devices to consumer products, this specialized tape provides reliable electromagnetic protection while maintaining the flexibility and ease of installation required for efficient manufacturing processes. The comprehensive customization options and global logistics support ensure that customers receive solutions perfectly tailored to their specific requirements and operational constraints.

As electromagnetic interference challenges continue to evolve with advancing technology and increasing device complexity, this innovative shielding tape provides the performance reliability and adaptability necessary for future-ready electronic designs. The commitment to quality excellence and continuous innovation ensures that customers receive not just a product, but a comprehensive solution that supports their success in competitive global markets.

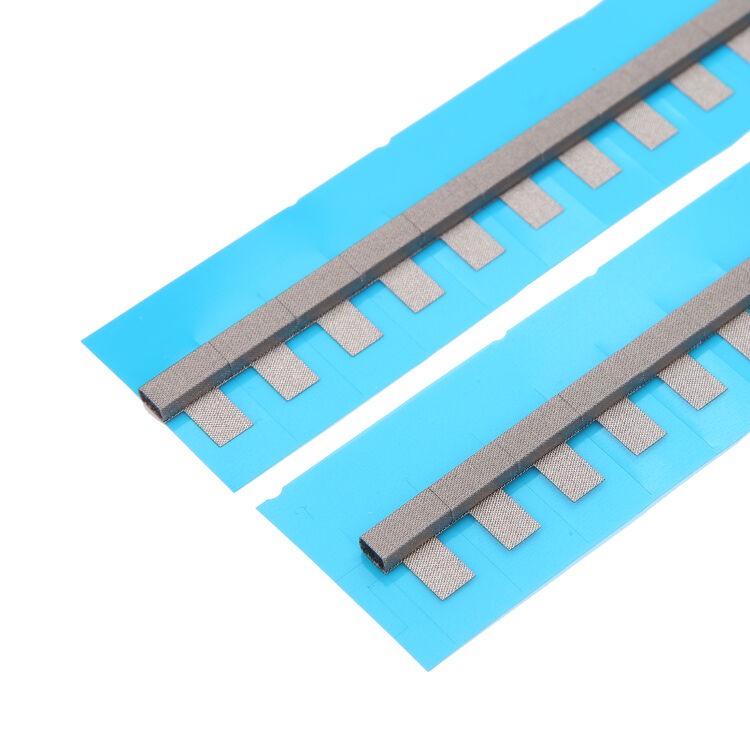

Professional EMI Shielding Tapes - Total Solution for RFI/ESD Protection

Excellent Shielding Performance |

Offers high shielding effectiveness over a wide frequency range, ideal for EMI, RFI, and ESD full protection. |

||||||

High Conductivity & Low Resistance |

Made from superior materials like nickel/copper coated fabric or pure copper foil, ensuring good electrical conductivity and reliable grounding. |

||||||

Flexible & Conformable |

Ultra-thin, flexible, and lightweight design allows for easy application on curved surfaces and tight spaces, such as internal circuit boards and flexible circuits. |

||||||

Customizable Solutions |

Available in custom sizes, shapes, and die-cuts (OEM/ODM supported). RoHS and REACH compliant to meet global environmental standards. |

||||||

Consumer Electronics |

Smartphones, laptops, gaming consoles, LCD displays, and 5G wireless chargers for internal circuit board shielding and high-speed HDMI signal protection. |

||||||

Automotive & Transportation |

Automotive electronics, autonomous vehicles LiDAR/Radar systems, and EV wireless chargers as part of robust EMC solutions. |

||||||

Telecom & Networking |

Networking equipment, 5G infrastructure, and cabinet shielding to ensure signal integrity and prevent interference. |

||||||

Industrial & Medical

|

Industrial control systems, power supplies, and sensitive medical electronic devices requiring reliable performance in demanding conditions. |

||||||

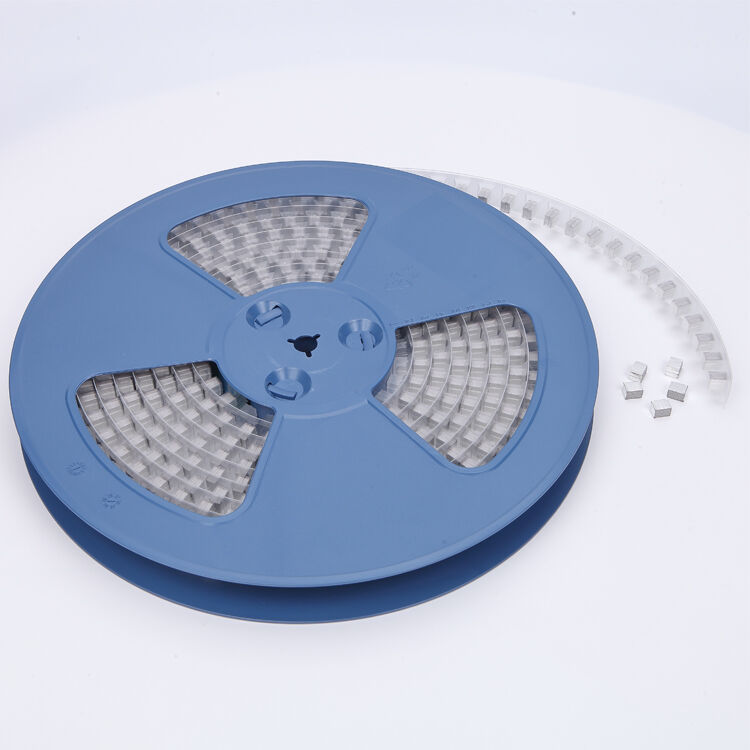

Available Types

Company Profile

We cater primarily to the consumer electronics, communication networks, and emerging energy vehicle sectors. To back ourcommitment to quality and innovation, we have established a national production base across four strategic locations:

1. A 1,000-square-meter new material formula R&D center in Shenzhen.

2. A 2,000-square-meter innovative grounding wrapping production plant in Dongguan.

3. A 10,000-square-meter conductive shielding tape coating plant in Hunan.

4. A 1,000-square-meter magnetron sputtering continuous gold/tin plating plant in Shandong.

As the only vertically integrated integrator in China offering electroplating, coating, and processing capabilities, we strive to become a leading innovator and provider of core values within the materials industry chain. Our ultimate goal is to be a long-term trusted solution provider and partner for our customers in addressing their challenges.

Invention Patent

System certification

FAQ

We are based in Guangdong, China, start from 2011,sell to South Asia(10.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Shielding tape,Adhesive tapes,Waterproof and breathable membrane,Customized production,Raw material die-cutting

4. why should you buy from us not from other suppliers?

Shenzhen Johan Material Tech Co., Ltd. was established in 2011, and is an innovative national high-tech enterprise providing

innovative EMC (electromagnetic compatibility) grounding elastomers and customized tape solutions for the electronics indus

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency: USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken: English,Chinese