Giriş

Günümüzde hızla gelişen elektronik endüstrisinde, hassas elektronik bileşenleri elektromanyetik girişim ve elektrostatik deşarjdan korumak giderek daha kritik hale gelmiştir. Yapışkanlı EMI Koruma İçin Die Cut Özelleştirilmiş Uygulamalarla Sünger Elastomer Esaslı İletken Köpük Conta modern elektronik cihaz üreticilerinin ve sistem entegratörlerinin zorlu gereksinimlerini karşılamak üzere tasarlanmış son teknoloji bir çözümdür. Bu gelişmiş iletken köpük conta, üstün elektromanyetik girişim kalkanlama özelliklerini, güçlü bir elektrostatik deşarj korumasıyla birleştirerek elektronik bütünlüğün ve güvenilirliğin ön planda olduğu uygulamalarda vazgeçilmez bir bileşen haline gelmiştir.

Elektronik cihazlar daha karmaşık ve kompakt hâle geldikçe, telekomünikasyon ve otomotivden havacılık ve tıbbi ekipmanlara kadar sektörlerde etkili EMI kalkanlaması ve ESD korumasına olan ihtiyaç artmıştır. İletken köpük conta teknolojimiz, belirli uygulama gereksinimlerine tam olarak uyarlanabilen, üstün iletkenlik ve dayanıklılık özelliklerini korurken yüksek performans sunan esnek bir çözüm sağlayarak bu zorluklara cevap verir.

Ürün Genel Bakış

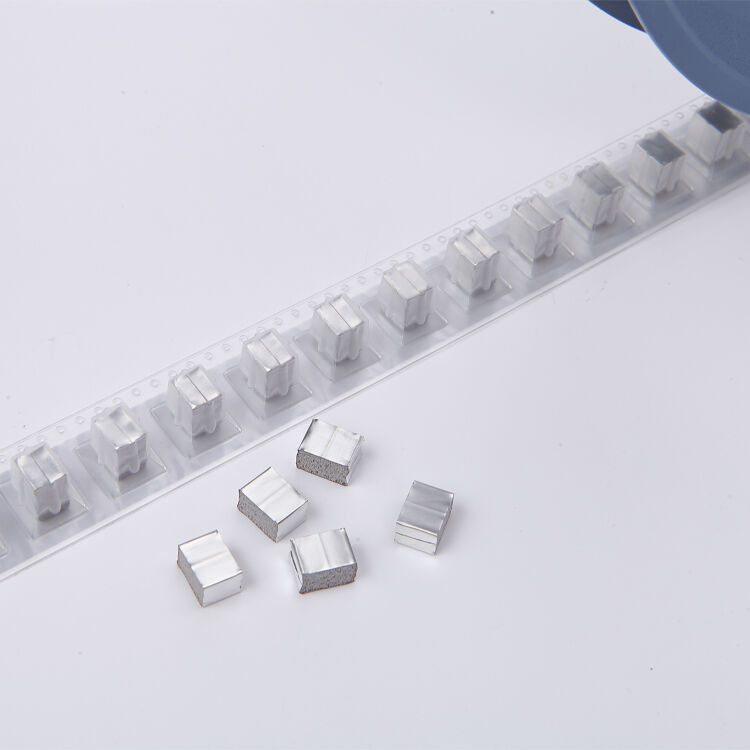

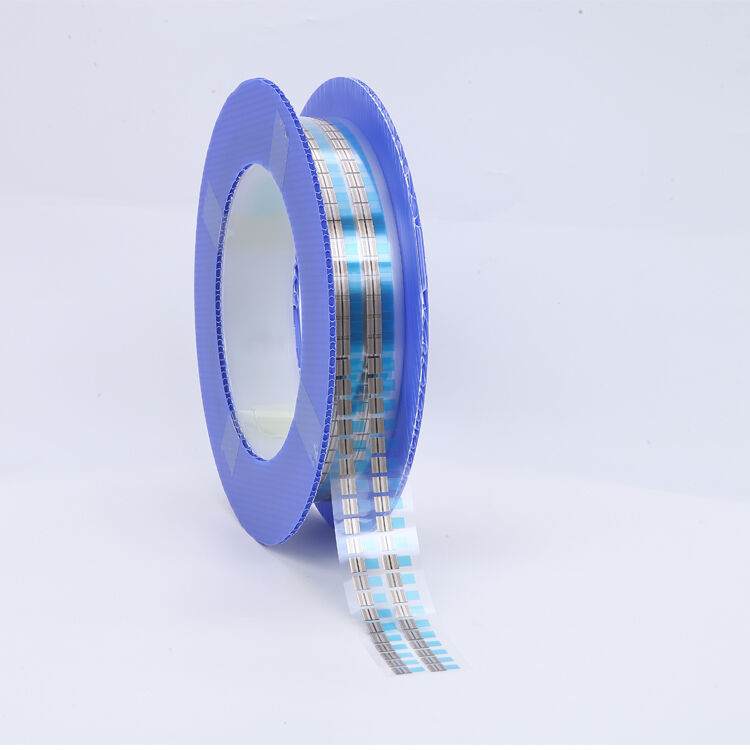

The Yapışkanlı EMI Koruma İçin Die Cut Özelleştirilmiş Uygulamalarla Sünger Elastomer Esaslı İletken Köpük Conta önemli elektromanyetik kalkanlama performansı sunmak üzere özel olarak geliştirilmiş ileri düzey elastomer malzemeler kullanılarak tasarlanmıştır. Sünger elastomer yapısı, conta yüzeyinde sürekli iletkenliği korurken mükemmel sıkıştırma özelliklerine sahiptir ve değişen çevre koşulları ile mekanik stres altında bile güvenilir performans sağlamayı mümkün kılar.

Bu yenilikçi conta çözümü, etkili EMI koruması için gerekli olan iletken özelliklerini zedelemeden çeşitli alt tabaka malzemelere güvenli şekilde bağlanmasını sağlayan özel yapışkanlı bir sistem içerir. Yapıştırıcı formülasyonu, güçlü bağlanma özelliğinin yanı sıra bakım veya değiştirme uygulamaları gerektiğinde gerektiğinde çıkarılabilir olacak şekilde optimize edilmiştir. İletken köpük yapı, elektronik montajlarda yaygın olarak karşılaşılan yüzey düzensizliklerini ve üretim toleranslarını karşılayarak korozyon etkinliğini artıran çoklu temas noktaları oluşturur.

Die-cut özelleştirme özelliği, özel muhafaza tasarımlarına ve bileşen konfigürasyonlarına tam olarak uyacak şekilde hassas şekillendirme ve boyutlandırma imkanı sağlar. Bu üretim esnekliği, malzeme israfını ve montaj karmaşıklığını en aza indirirken optimal uyum ve performansı garanti eder. Contanın hücreli köpük yapısı, uzun süreli kullanım döngüleri boyunca sürekli contalama ve koruma performansını koruyarak mükemmel sıkışma dayanımı ve geri dönüş özelliğine sahiptir.

Özellikler ve faydalar

Gelişmiş Malzeme Özellikleri

Bu iletken köpük conta üzerindeki elastomerik yapı, zorlu uygulamalarda uzun vadeli performans için gerekli olan olağanüstü mekanik özellikler sunar. Malzeme, conta uzun süreli sıkıştırma döngülerinin ardından bile orijinal kalınlığını ve contalama özelliklerini korumasını sağlayan üstün sıkıştırma dayanımı direncine sahiptir. Bu dayanıklılık, termal çevrimlerin veya mekanik titreşimlerin zamanla conta performansını etkileyebileceği uygulamalarda özellikle önemlidir.

İletken özellikler, elastomerik matris boyunca eşit şekilde dağıtılan özel iletken dolgu maddeleri eklenerek elde edilir. Bu yaklaşım, etkili sızdırmazlık uygulamaları için önemli olan esnekliği ve sıkıştırılabilirliği korurken, conta yüzeyinin tamamında tutarlı elektrik iletkenliği sağlar. Elde edilen malzeme, iletken ve elastomerik malzemelerin en iyi özelliklerini birleştirerek karmaşık kalkanlama gereksinimleri için dengeli bir çözüm sunar.

Elektromanyetik Girişim Korumada Mükemmellik

The Yapışkanlı EMI Koruma İçin Die Cut Özelleştirilmiş Uygulamalarla Sünger Elastomer Esaslı İletken Köpük Conta geniş bir frekans spektrumunda olağanüstü elektromanyetik girişim zayıflatma özelliklerini gösterir. İletken köpük yapısı, doğru şekilde monte edildiğinde etkili bir Faraday kafesi etkisi yaratır ve elektromanyetik enerjinin elektronik muhafazalara girmesini veya dışarı çıkmasını engeller. Bu koruma özelliği, düzenleyici uyumluluğun korunması ve elektromanyetik açıdan zorlu ortamlarda cihaz performansının en iyi düzeyde tutulması açısından hayati öneme sahiptir.

Contanın hücresel yapısı, mekanik esnekliği korurken genel koruma etkinliğini artıran çok sayıda paralel iletken yol sağlar. Bu tasarım yaklaşımı, contanın montaj ve çalışma sırasında sıkıştırmaya veya deformasyona maruz kalması durumunda bile koruma performansının tutarlı kalmasını sağlar. Sonuç olarak, hassas elektronik bileşenleri dış müdahalelerden koruyan ve cihaz emisyonlarının yakındaki ekipmanı etkilemesini önleyen güvenilir bir elektromanyetik bariyer elde edilir.

Elektrostatik deşarj koruma

Elektromanyetik kalkıtmayı aşarak, bu iletken köpük conta hassas elektronik bileşenler için kritik bir elektrostatik deşarj koruması sağlar. Kontrollü iletkenlik özellikleri, statik yüklerin yarı iletken cihazlara zarar vermesine veya sistem çalışmasını bozmasına neden olabilecek ani deşarj olayları oluşturmadan güvenli bir şekilde dağılmasını sağlar. Bu ESD koruma özelliği, statik elektrik üretiminin kaçınılmaz olduğu üretim ortamlarında ve uygulamalarda özellikle değerlidir.

Contanın ESD koruma işlevi sürekli olarak çalışır ve potansiyel olarak zarar verebilecek elektriksel potansiyellerin birikmesini önleyen sürekli statik yük dağılımı sağlar. Statik kontrol konusundaki bu proaktif yaklaşım, korumalı elektronik sistemlerin güvenilirliğini ve ömrünü sağlamakta yardımcı olurken elektrostatik hasara ilişkin saha arızaları riskini de azaltır.

Uygulamalar & Kullanım Alanları

Çok yönlülük özelliği sayesinde Yapışkanlı EMI Koruma İçin Die Cut Özelleştirilmiş Uygulamalarla Sünger Elastomer Esaslı İletken Köpük Conta birden fazla sektördeki elektronik uygulamalar için uygun hale getirir. Telekomünikasyon ekipmanlarında, bu conta cihazları elektromanyetik uyumluluk açısından doğru çalışmanın ve yönetmeliklere uyumun kritik olduğu baz istasyonları, yönlendiriciler ve anahtarlama ekipmanları için gerekli EMI koruması sağlar. Contalar, kapsamlı koruma sağlayabilmek için elektriksel sürekliliğin korunmasını sağlarken aynı zamanda muhafaza bağlantı noktalarını ve erişim panellerini etkili bir şekilde sızdırmaz hale getirir.

Otomotiv elektroniği uygulamaları, bu iletken köpük conta teknolojisinin önemli bir kullanım alanı olarak öne çıkmaktadır. Modern araçlar, ateşleme sistemleri, elektrik motorları ve kablosuz iletişim cihazları tarafından oluşturulan elektromanyetik açıdan zorlu ortamda güvenilir şekilde çalışmak zorunda olan çok sayıda elektronik kontrol modülü içerir. Bu contalar, motor kontrol üniteleri, bilgi-eğlence sistemleri ve güvenlik açısından kritik bileşenler için etkili bir koruma sağlarken otomotiv uygulamalarıyla ilişkili termal ve mekanik streslere de dayanıklıdır.

Tıbbi cihaz üreticileri, hassas tanı ve tedavi ekipmanlarının dış elektromanyetik kaynaklardan kaynaklanan etkileşim olmadan çalışmasını sağlamak için bu iletken conta kullanır. Contalar, tıbbi görüntüleme sistemlerinin, hasta izleme cihazlarının ve implant edilebilir cihaz programlayıcılarının bütünlüğünü korurken pahalı elektronik bileşenlere zarar verilmesini önlemek için gerekli ESD korumasını sağlar. Tıbbi uygulamalar için mevcut olan biyouyumlu malzeme seçenekleri, ilgili sağlık ve güvenlik yönetmeliklerine uyumu sağlar.

Havacılık ve savunma uygulamaları, elektromanyetik kalkanlama performansının en yüksek seviyelerini gerektirir ve bu iletken köpük conta, bu katı gereksinimleri karşılar. Contalar, sıcaklık değişimleri, irtifa değişiklikleri ve titreşim maruziyeti dahil olmak üzere aşırı çevre koşullarında güvenilir performansı korurken, aviyonik sistemler, radar ekipmanları ve iletişim cihazları için etkili EMI koruması sağlar. Köpük malzemenin hafif yapısı, ağırlığa duyarlı havacılık uygulamalarında özellikle avantajlıdır.

Kalite kontrolü ve uyumluluk

İmalat mükemmelliği, ürünün performansı ve güvenilirliği açısından temel öneme sahiptir Yapışkanlı EMI Koruma İçin Die Cut Özelleştirilmiş Uygulamalarla Sünger Elastomer Esaslı İletken Köpük Conta . Üretim tesislerimiz, tüm üretilen ürünlerde tutarlı malzeme özellikleri ve boyutsal doğruluk sağlayacak kapsamlı kalite yönetim sistemlerini uygular. Her bir iletken köpük malzeme partisi, kesme ve imalat işlemlerine gönderilmeden önce elektrik iletkenliği, mekanik özellikleri ve yapıştırıcı performans karakteristikleri açısından titizlikle test edilir.

Kesme işlemi itself, hassas boyutsal doğruluk ve temiz kenar kalitesini garanti altına alan katı kalite kontrollerine tabidir. İleri düzey kesme teknolojileri ve kalıp bakım programları, her özel conta belirtilen boyutsal toleranslara uygun şekilde üretilirken malzeme bütünlüğünün optimal performans için korunmasını sağlar. Kesim sonrası muayene prosedürleri, ambalajlanma ve sevkiyat öncesinde tüm contaların müşteri spesifikasyonlarını ve kalite standartlarını karşıladığını doğrular.

Çevresel ve düzenleyici uyum, kalite güvence programımızın kritik bir yönünü temsil eder. Conta üretiminde kullanılan malzemeler, RoHS direktifleri ve REACH gereksinimleri dahil olmak üzere ilgili çevresel düzenlemelere uygunluk açısından değerlendirilir. Düzenleyici uyuma bu şekilde bağlılık, contalarımızın küresel pazarlarda sınırlamadan kullanılabileceğini ve müşterilerimizin kendi uyum hedeflerini desteklediğini garanti eder.

İzlenebilirlik sistemleri, üretilen her conta için malzeme kaynaklarına, üretim parametrelerine ve kalite test sonuçlarına dair ayrıntılı kayıtları tutar. Bu kapsamlı belgelendirme, gerekli olduğunda kök neden analizini destekler ve kalite denetimleri ile müşteri gereksinimleri için gerekli izlenebilirlik bilgilerini sağlar. Titiz kalite kontrolleri ile ayrıntılı belgelendirmenin birleşimi, müşterilerin performans beklentilerini karşılayan tutarlı, yüksek kaliteli ürünler almasını sağlar.

Özelleştirme ve Markalama Seçenekleri

Kalıp kesim özelleştirme kabiliyeti Yapışkanlı EMI Koruma İçin Die Cut Özelleştirilmiş Uygulamalarla Sünger Elastomer Esaslı İletken Köpük Conta özel uygulama gereksinimlerini ve tasarım sınırlamalarını karşılamak için hassas bir şekilde uyarlanmasını sağlar. Gelişmiş die-cutting teknolojilerimiz, müşterinin kabinet tasarımına tam olarak uyacak karmaşık geometrileri, çoklu açıklıkları ve ince detayları içeren neredeyse her şekil ve yapıdaki conta üretimi yapabilir. Bu özelleştirme esnekliği, ikincil işlemlere olan ihtiyacı ortadan kaldırırken son uygulamada optimal oturmayı ve performansı garanti eder.

Malzeme kalınlığı seçenekleri, sıkıştırma gereksinimleri ile mevcut yer sınırlamaları arasında denge kurulmasına imkan tanıyan ekstra özelleştirme olanakları sunar. Hücreli köpük yapısı, belirli sıkıştırma karakteristikleri için optimize edilebilir ve böylece uygulama ihtiyaçlarına göre sızdırmazlık kuvveti ile EMI koruma performansının hassas ayarı yapılabilir. Standart özelliklerin ötesinde özel elektriksel, termal veya kimyasal direnç özellikleri gerektiren uygulamalar için özel malzeme formülasyonları da mevcuttur.

Yapışkan arka yapılandırmaları, altlık malzemelerine ve montaj gereksinimlerine göre özelleştirilebilir. Seçenekler arasında tam yüzey kaplama yapışkan, kısmi yapışkan desenleri ve bakım ve değiştirme işlemlerini kolaylaştıran çıkarılabilir yapışkan formülasyonları yer alır. Yapışkan seçimi süreci, conta kullanım ömrü boyunca optimal performansı sağlamak amacıyla altlık uyumluluğu, çevresel etkiler ve gerekli bağlanma dayanımı gibi faktörleri dikkate alır.

OEM üreticiler ve özel marka uygulamaları için marka kimliğini desteklemek ve envanter yönetimi gereksinimlerini karşılamak üzere özel ambalajlama ve etiketleme seçenekleri mevcuttur. Bireysel conta ambalajları, ürünleri nakliye ve depolama sırasında korurken verimli montaj süreçlerini de kolaylaştırır. Özel parça işaretlemesi ve tanımlama sistemleri, üretim ortamlarında montaj hatalarını önlemeye ve kalite kontrol prosedürlerini desteklemeye yardımcı olur.

Ambalaj ve Lojistik Desteği

Etkili ambalajlama ve lojistik desteği, ürünlerin Yapışkanlı EMI Koruma İçin Die Cut Özelleştirilmiş Uygulamalarla Sünger Elastomer Esaslı İletken Köpük Conta müşteri tesislerine kusursuz durumda ve hemen kullanılabilir şekilde ulaşır. Ambalaj sistemlerimiz, yapışkan bütünlüğü, boyutsal doğruluk ve temizlik dahil olmak üzere conta özelliklerinin dağıtım süreci boyunca korunmasını sağacak şekilde tasarlanmıştır. Antistatik ambalaj malzemeleri, contaların ESD koruma özelliklerini korurken elektrostatik hasarı önler.

Ambalaj konfigürasyonları, prototip uygulamalar için tek tek conta korumasından yüksek hacimli üretim kullanımına yönelik toplu ambalajlara kadar farklı sipariş miktarlarına ve müşteri gereksinimlerine göre optimize edilmiştir. Nemi engelleyen ambalaj, depolama ve taşıma sırasında yapışkan özelliklerini koruyarak sevkiyat sırasında karşılaşılan çevresel koşullardan bağımsız olarak tutarlı yapışma performansı sağlar. Açık etiketleme ve tanımlama sistemleri, envanter yönetimini kolaylaştırır ve müşterinin teslim alma ve depolama işlemlerinde karışıklığı önler.

Küresel lojistik kapasiteleri, uluslararası müşterilere güvenilir sevkiyat seçenekleri ve gümrük işlemleri ile ithalat prosedürleri için kapsamlı belgelerle destek olur. Lojistik ortaklarımız, taşıma süreci boyunca sorumluluğu sağlayacak şekilde takip ve teslimat onayı hizmetleri sunar. Bölgesel dağıtım kapasiteleri, teslimat sürelerini ve taşıma maliyetlerini azaltırken acil ihtiyaçlar ve acil siparişler için yerel destek sağlar.

Stok yönetimi destek hizmetleri, müşterilerin üretim programları için ürün uygunluğunu sağlarken kendi stok seviyelerini optimize etmelerine yardımcı olur. Tedarikçi tarafından yönetilen stok programları ve planlı teslimat seçenekleri, müşteri stok bulundurma maliyetlerini azaltırken üretim esnekliğini koruyan öngörülebilir tedarik zincirleri sağlar. Bu lojistik destek hizmetleri, müşterilerin başarısı için iletken köpük contalarımızın teknik kapasitelerini tamamlayan kapsamlı çözümler sunar.

Neden Bizi Seçmelisiniz

Hassas kalıp kesme ve iletken malzeme teknolojilerinde geniş deneyime sahip önde gelen bir metal ambalaj üreticisi olarak, şirketimiz gelişmiş EMI koruma çözümlerinin geliştirilmesi ve üretiminde yılların birikimiyle kazanılan uzmanlığı getiriyor. Uluslararası pazarlardaki varlığımız birkaç kıtaya yayılmış olup, müşterilere dünya çapında hizmet verirken sürekli kalite standartlarını ve teknik destek kabiliyetlerini korumamızı sağlıyor. Bu küresel erişim, yerel teknik uzmanlıkla birleşerek konumlarından veya pazar gereksinimlerinden bağımsız olarak müşterilerin ihtiyaç duydukları desteği almasını garanti altına alıyor.

Güvenilir özel teneke kutu tedarikçisi ve OEM teneke ambalaj çözümleri sağlayıcısı olarak, hassas imal edilmiş bileşenlere ve güvenilir tedarik zinciri performansına ihtiyaç duyan çeşitli sektörlerle ilişkiler kurduk. Bu çoklu sektör uzmanlığı sayesinde farklı pazar segmentlerinin karşılaştığı benzersiz zorlukları anlayabiliyor, maliyet etkinliği ve güvenilirliği korurken spesifik uygulama gereksinimlerini karşılayan çözümler geliştirebiliyoruz.

Bizi tercih edilen bir metal ambalaj tedarikçisi yapan teknik yetenekler, başarı için hassas üretim ve malzeme uzmanlığının eşit derecede önemli olduğu iletken köpük conta uygulamalarına doğal olarak uzanmaktadır. İleri düzey üretim teknolojilerine ve kalite kontrol sistemlerine yaptığımız yatırımlar, her bir contanın EMI kalkanlama ve ESD koruma uygulamaları için gerekli olan yüksek standartlara tam olarak uygun olmasını sağlamaktadır. Bu mükemmellik taahhüdü, dünya çapında müşterilerden takdir toplamış ve karmaşık teknik zorluklara çözüm sunan yenilikçi çözümler sunma itibarımızı oluşturmuştur.

İş birliği yapılan mühendislik desteği, müşterilerin üretilebilirlik açısından tasarımlarını optimize etmelerine ve performans hedeflerine ulaşmalarına yardımcı olur. Teknik ekibimiz, uygulama gereksinimlerini değerlendirmek, malzeme seçimlerini önermek ve maliyetleri en aza indirirken performansı en üst düzeye çıkaran özel çözümler geliştirmek amacıyla müşteri mühendisleriyle yakın şekilde çalışır. Bu iş birliğine dayalı yaklaşım, müşterilerin yalnızca yüksek kaliteli ürünler değil, aynı zamanda proje hedeflerine verimli ve etkili bir şekilde ulaşmak için gerekli teknik uzmanlığı da almasını sağlar.

Sonuç

The Yapışkanlı EMI Koruma İçin Die Cut Özelleştirilmiş Uygulamalarla Sünger Elastomer Esaslı İletken Köpük Conta günümüz elektronik cihaz üreticilerinin karşılaştığı elektromanyetik uyumluluk ve elektrostatik deşarj koruma zorlukları için gelişmiş bir çözüm sunar. İleri düzey elastomerik malzemelerin, hassas die-cut yeteneklerin ve kapsamlı özelleştirme seçeneklerinin bir araya getirilmesiyle bu conta, çeşitli uygulama alanlarında ve sektörlerde güvenilir performans sağlar. Tek bir kolay montajlı bileşene EMI kalkanlama ve ESD koruma işlevlerinin entegre edilmesi, tasarım gereksinimlerini basitleştirirken hassas elektronik sistemler için kapsamlı koruma sağlar. Kanıtlanmış kalite kontrol süreçleri, küresel lojistik desteği ve iş birliğine dayalı mühendislik uzmanlığı ile iletken köpük conta çözümlerimiz, rekabetçi küresel pazarlarda başarı için gerekli olan performansı, güvenilirliği ve değeri sunar.

Johan ECF (Elastik İletken Köpük)

Teknik veri sayfası

|

Güncellenme: Mayıs, 2021

|

||

Tanım

|

Bu topraklama köpüğü, yüksek sekme elastomer esaslıdır ve süper ince iletken kumaş veya film ile birlikte çok ince alanlarda yüksek düzeyde topraklama için uygundur. benzersiz yapısı sayesinde düşük elektrik direnci ve stabil fiziksel özellikler gösterir zorlu çevre testlerinden sonra bile özelliklerini korur. |

||

Yapı

Uygulama

Tipik Fiziksel Özellikler |

Aşağıdaki teknik bilgiler ve veriler yalnızca temsili veya tipik kabul edilmelidir ve spesifikasyon amaçları için kullanılmamalıdır. |

Sıkıştırma Oranı |

0% |

30% |

50% |

70% |

Geçiş Direnci (Ω) |

0.179 |

0.080 |

0.051 |

0.045 |

Sıkıştırma Oranı |

0% |

30% |

50% |

70% |

Geçiş Direnci (Ω) |

0.201 |

0.115 |

0.070 |

0.058 |

Diğer boyutlar talep üzerine özelleştirilebilir.

(Au kaplama işlemi yapılan kumaş/film, LCD dahil olmak üzere yüksek tazeleme hızına sahip ekranlarda daha iyi çalışır ve zamanla daha kararlı performans sunar)

(Çalışma Yüksekliği: 0,20 mm ECF-SF-05S3 Kumaş-Ni Kaplama)

(Çalışma Yüksekliği: 0,30 mm ECF-SF-07S3 Kumaş-Ni Kaplama)

(Çalışma Yüksekliği: 0.20mm ECF-SF-05S3GP Kumaş-Au-Kaplama)

(Çalışma Yüksekliği: 0.33mm ECF-SF-07S3GP Kumaş-Au-Kaplama)

Şirket Profili

Tüketici elektroniği, iletişim ağları ve yeni enerji araçları sektörlerine öncelikle hizmet veriyoruz. Kaliteye ve inovasyona olan bağlılığımızı desteklemek için dört stratejik konumda ulusal bir üretim tesisi kurduk:

1. Şenzhen'de 1.000 metrekarelik yeni malzeme formülü Ar-Ge merkezi.

2. Dongguan'da 2.000 metrekarelik yenilikçi topraklama sarma üretim tesisi.

3. Hunan'da 10.000 metrekarelik iletken elektromanyetik koruma bant kaplama tesisi.

4. Shandong'da 1.000 metrekarelik magnetron sputter ile sürekli altın/kalay kaplama tesisi.

Kaplamacılık, sırlama ve işleme yeteneklerini sunan Çin'deki tek dikey entegre edilmiş entegratör olarak, malzeme endüstrisi zincirinde öncü bir inovatör ve temel değer sağlayıcısı olmayı amaçlıyoruz. Nihai hedefimiz, müşterilerimizin zorluklarını çözmeleri için uzun vadeli güvenilir çözüm sağlayıcısı ve ortağı olmaktır.

Sistem sertifikasyonu

İcat Patenti

SSS

Çin'in Guangdong eyaletinde bulunuyoruz, 2011 yılından beri faaliyet gösteriyoruz ve Güney Asya'ya satıyoruz (%10,00). Ofisimizde yaklaşık 101-200 kişi bulunmaktadır.

2. kalitemizi nasıl garanti edebiliriz?

Toplu üretimden önce her zaman bir ön üretim örneği yaparız;

Gönderimedan önce her zaman son denetim yapılır;

3. bizden ne satın alabilirsiniz?

Koruyucu bant, Yapışkanlı bantlar, Su geçirmez ve nefes alan membran, Özel üretim, Ham madde die-cutting

4. neden bizden satın almalısınız, diğer tedarikçilerden değil?

Shenzhen Johan Material Tech Co., Ltd. 2011 yılında kurulmuştur ve inovatif bir ulusal yüksek teknoloji işletmesidir.

elektronik endüstrisi için yenilikçi EMC (elektromanyetik uyumluluk) topraklama elastomerleri ve özelleştirilmiş bant çözümleri

5. hangi hizmetleri sunabiliriz?

Kabul edilen teslimat şartları: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Kabul edilen ödeme para birimi: USD,EUR,JPY,CAD,AUD,HKD,GBP,Cny,CHF;

Kabul Edilen Ödeme Türü: T/T,L/C,D/P D/A,MoneyGram,Kredi Kartı,PayPal,Western Union,Nakit,Escrow;

Konuşulan dil: İngilizce,Çin