Giriş

Günümüzde hızla gelişen telekomünikasyon ve ağ iletişimi dünyasında, elektromanyetik girişim (EMI) koruması, ekipmanların optimal performansını korumak için kritik bir gereklilik haline gelmiştir. Ağ Ekipmanları İçin Kumaş Kaplı Sünger Conta modern elektronik sistemlerin karşılaştığı karmaşık koruma zorluklarını çözmek amacıyla tasarlanmış gelişmiş bir çözümdür. Bu yenilikçi conta teknolojisi, köpük alt tabakalarının esnekliğini özel kumaşların üstün iletkenliğiyle birleştirerek elektromanyetik radyasyona karşı etkili bir bariyer oluşturur ve çeşitli ağ uygulamalarında güvenilir sinyal bütünlüğünü sağlar.

Ağ altyapısının küresel olarak genişlemeye devam etmesiyle, yüksek performanslı EMI koruma çözümlerine olan talep önemli ölçüde arttı. Profesyonel seviye iletken conta, hassas elektronik devreleri dış etkilerden korurken sistemin işlevini tehlikeye atan iç sinyal sızıntısını engellemek açısından kritik bileşenlerdir. Köpük üzerine iletken kumaş teknolojisinin entegrasyonu, kurumsal düzey ağ ekipmanları, telekomünikasyon altyapıları ve endüstriyel otomasyon sistemlerinin katı gereksinimlerini karşılayan olağanüstü performans özellikler sunmaktadır.

Ürün Genel Bakış

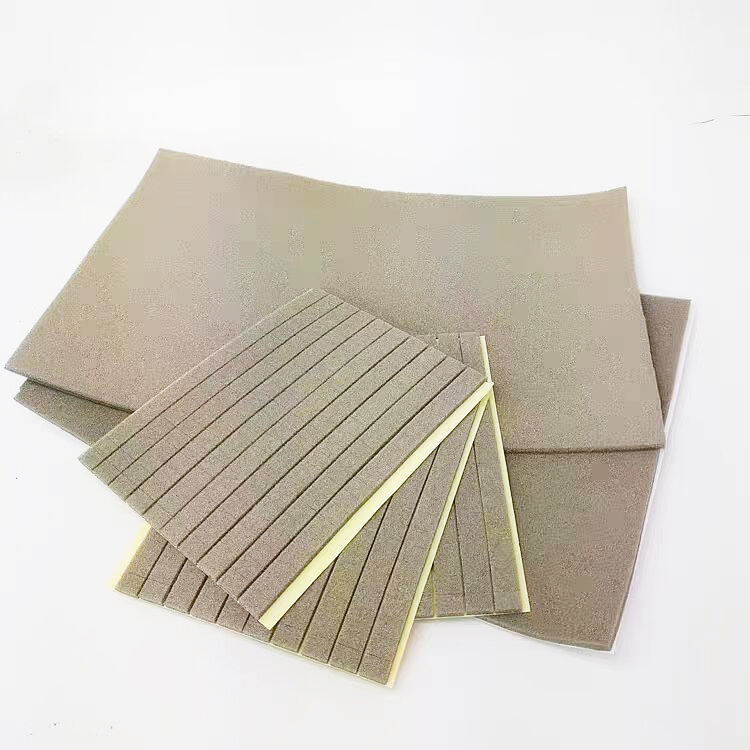

The Ağ Ekipmanları İçin Kumaş Kaplı Sünger Conta hem koruyucu etkinliği hem de mekanik performansı en üst düzeye çıkaran benzersiz bir kompozit yapıya sahiptir. Temel, değişen çevre koşullarında mükemmel sıkıştırma özellikleri ve uzun süreli dayanıklılık sağlayan hassas mühendislikle tasarlanmış bir köpük çekirdeğinden oluşur. Bu köpük alt tabaka, ürün ömrü boyunca güvenilir EMI koruması sağlayarak conta yüzeyinin tamamında tutarlı elektriksel sürekliliği koruyan yüksek performanslı iletken kumaşla titizlikle kaplanmıştır.

Bu gelişmiş conta tasarımı, korozyona, oksidasyona ve çevresel bozunmaya karşı üstün direnç gösteren özel iletken malzemeleri içerir. Kumaş katmanı, düzensiz yüzeylere karşı etkili bir sızdırmazlık sağlarken optimal iletkenliği koruyan dikkatle seçilmiş metalik lifler veya iletken kaplamalar kullanır. Bu malzemelerin birleşimi, geleneksel kalkanlama yöntemlerinin yetersiz kalabileceği zorlu ağ ortamlarında olağanüstü performans sunan bir conta çözümü oluşturur.

İmalat hassasiyeti, contanın performans özelliklerinde kritik bir rol oynar ve her birim, tutarlı kalite ve güvenilirliği sağlamak için kontrollü koşullar altında üretilir. İletken kumaş uygulama süreci, köpük alt tabakasına uniform kaplama ve yapışmayı garanti eden özel teknikleri içerir ve elektromanyetik korumayı etkileyebilecek potansiyel zayıf noktaları ortadan kaldırır. Üretim detaylarına bu dikkat, kritik ağ uygulamaları için gerekli olan yüksek standartları consistently karşılayan bir ürün ortaya çıkarır.

Özellikler ve faydalar

Üstün Elektromanyetik Kalkanlama Performansı

Ağ ekipmanları için iletken kumaş üzeri köpük contanın en önemli avantajı, olağanüstü elektromanyetik koruma yeteneklerinde yatmaktadır. İletken kumaş katmanı, korunan ekipmanın etrafında sürekli bir Faraday kafesi etkisi yaratarak, elektromanyetik radyasyonun hem elektrik hem de manyetik alan bileşenlerini etkili bir şekilde zayıflatır. Bu kapsamlı koruma, hassas ağ bileşenlerinin dış parazit kaynaklarından izole kalmasını sağlarken, yakındaki ekipmanı etkileyebilecek veya düzenleyici emisyon standartlarını ihlal edebilecek iç sinyal sızıntısını da önler.

Contanın koruyucu etkinliği, geniş bir frekans spektrumu boyunca tutarlı kalır ve bu da onu aynı anda birden fazla frekans bandında çalışan modern ağ cihazları için özellikle değerli hale getirir. Zamanla boşluklar veya süreksizlikler geliştirebilen sert metal koruyucuların aksine, esnek kumaş yapısı eşleşen yüzeylerle sürekli temas halinde kalır ve böylece termal çevrim, titreşim veya mekanik gerilim altında bile güvenilir koruma sağlar.

Geliştirilmiş Mekanik Özellikler ve Dayanıklılık

Köpük malzeme, conta boyunca etkili sızdırmazlık performansını uzun süreli kullanım dönemlerinde korumasını sağlayan olağanüstü sıkışma ve geri kazanım özelliklerine sahiptir. Bu mekanik dayanıklılık, bileşenlerin bakım veya güncellemeler için sıkça erişilmesi gereken ağ cihazı uygulamalarında özellikle önemlidir. Köpüğün hücre yapısı, sıkıştırma kuvvetlerini eşit şekilde dağıtır ve erken hasar riski veya sızdırmazlık performansındaki düşüşlere neden olabilecek yerel stres yoğunlaşmalarını önler.

Çevresel direnç, bu conta tasarımının bir diğer önemli avantajıdır ve iletken kumaş, köpük malzemeyi aksi takdirde tehlikeye atabilecek nem, toz ve kimyasal kirleticilere karşı korur. Kumaş katmanı, contanın temel kalkan fonksiyonunu korurken aynı zamanda koruyucu bir bariyer olarak işlev görür ve zorlu ortamlarda çalışma ömrünü uzatır ve bakım gereksinimlerini azaltır.

Çeşitli Kurulum ve Uyumluluk

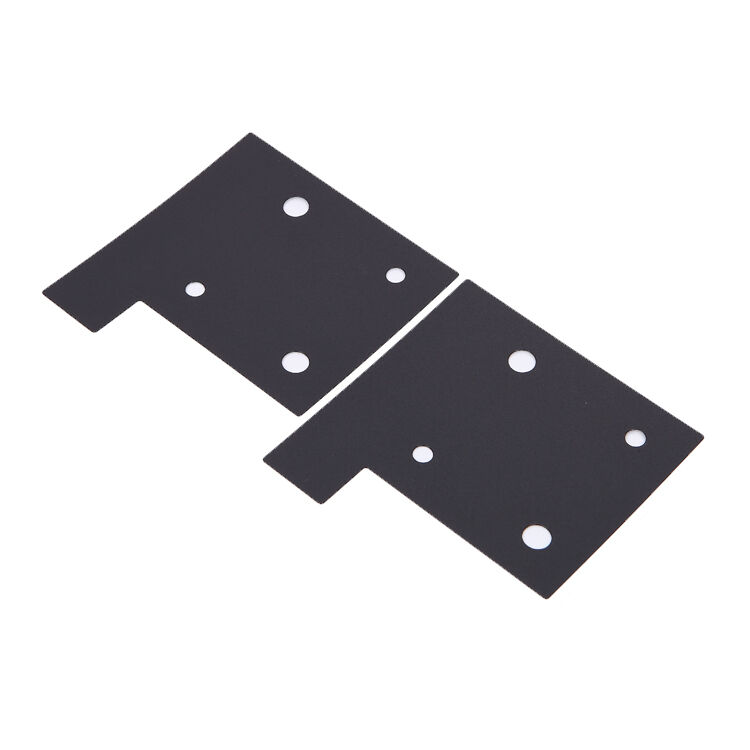

Ağ Ekipmanları için İletken Kumaşlı Köpük Contanın esnek yapısı, çeşitli ekipman konfigürasyonları ve muhafaza tasarımlarında kolay kurulum imkânı sunar. Bu conta, düzensiz yüzeylere kolayca uyar ve sert conta malzemeleriyle etkili bir şekilde kapatılamayabilecek üretim toleranslarını karşılar. Bu uyum sağlama özelliği, montaj işlemlerini basitleştirir ve sistemin performansını olumsuz etkileyebilecek montaj hatalarının meydana gelme ihtimalini azaltır.

Standart conta yuvası tasarımları ve montaj yöntemleriyle uyumluluk, önemli tasarım değişiklikleri gerektirmeden mevcut ekipman mimarilerine sorunsuz entegrasyon sağlar. Contanın tutarlı kesitsel özellikleri, tahmin edilebilir sıkıştırma karakteristikleri sunar ve mühendislerin montaj parametrelerini doğru şekilde belirlemesine ve üretim miktarlarında optimal conta performansı elde etmesine olanak tanır.

Uygulamalar & Kullanım Alanları

Ağ Ekipmanları için Köpük Conta Üzerindeki İletken Kumaş, telekomünikasyon ve ağ endüstrisinin çeşitli sektörlerinde yaygın olarak kullanılmaktadır. Kurumsal ağ ortamlarında bu conta türleri, kurumsal veri altyapısının temelini oluşturan anahtarlar, yönlendiriciler ve geçit cihazları için gerekli olan EMI korumasını sağlar. Contalar, yüksek hızlı veri iletim ekipmanlarının güvenilir çalışmasını sağlarken ticari tesislerle ilgili düzenlemeler kapsamında elektromanyetik uyumluluk yönetmeliklerine uyumunu da sürdürür.

Telekomünikasyon hizmet sağlayıcıları, baz istasyonları, sinyal işleme üniteleri ve ağ yönetim sistemleri gibi kritik altyapı ekipmanlarını korumak için bu özel conta çözümlerine güvenir. Dış mekânda kurulan telekomünikasyon tesislerinde karşılaşılan zorlu çevre koşulları, sıcaklık uçurumlarına, nem değişimlerine ve atmosferik kirleticilere maruz kalmaya rağmen sürekli koruma performansını koruyabilen conta çözümleri gerektirir. İletken kumaş kaplı köpük contaların dayanıklı yapısı, bu zorlu uygulamalar için onları ideal bir tercih haline getirir.

Endüstriyel otomasyon ve kontrol sistemleri, elektromanyetik girişimin ciddi işletme sonuçlarına yol açabileceği başka önemli bir uygulama alanıdır. İmalat tesisleri, enerji üretim santralleri ve ulaşım sistemleri, yüksek güçlü makinelerin, değişken frekans sürücülerinin ve anahtarlama ekipmanlarının bulunduğu elektriksel olarak gürültülü ortamlarda güvenilir şekilde çalışması gereken ağ ekipmanlarını kullanır. Bu conta malzemelerinin üstün koruma etkinliği, kritik kontrol sistemleri ile izleme ekipmanları arasındaki iletişimin kesintisiz olmasını sağlayarak operasyonel sürekliliğe katkıda bulunur.

Askeri ve havacılık uygulamaları, iletişim ekipmanlarının hassas yapısı ve sistem arızalarının olası sonuçları nedeniyle en yüksek düzeyde elektromanyetik koruma gerektirir. Ağ Ekipmanları için Köpük Üzeri İletken Kumaş Conta, kritik öneme sahip görev uygulamaları için gerekli performans güvenilirliğini sağlarken, özel ekipman tasarımlarında sıkça karşılaşılan karmaşık geometrileri karşılamak için gerekli esnekliği de sunar.

Kalite kontrolü ve uyumluluk

Conta üretim sürecinin hammadde seçimi ile başlayıp nihai muayene ve ambalajlama aşamasına kadar tüm süreçlerinde titiz kalite kontrol süreçleri uygulanır. Gelişmiş test yöntemleri, her üretim partisinin elektriksel ve mekanik özelliklerini doğrular ve belirtim gereksinimlerini karşılayan ya da aşan tutarlı performans karakteristiklerini garanti eder. Bu kapsamlı kalite güvence önlemleri, müşterilere ürün güvenilirliği ve uzun vadeli performans konusunda güven verir.

İmalat süreci, kritik parametrelerin belirlenmiş standartlara karşı doğrulandığı birden fazla kontrol noktasını içerir. İletken kumaş yapışması, köpük yoğunluğu homojenliği ve boyutsal hassasiyet üretim izleme sırasında özellikle dikkate alınır. İstatistiksel süreç kontrol yöntemleri, ürün kalitesini etkileyebilecek herhangi bir sapmayı erken tespit etmeyi ve üretim standartlarını korumak amacıyla anında düzeltici önlemler almayı sağlar.

Uluslararası elektromanyetik uyumluluk standartlarına uyum, ağ cihazları contaları için temel bir gerekliliktir. Ağ Cihazları İçin Köpüğün Üzerinde İletken Kumaşlı Conta, ilgili EMC direktiflerine ve sektöre özel standartlara uygunluğunu doğrulamak amacıyla kapsamlı testlere tabi tutulur. Bu testler, bireysel conta performansını ve temsili ekipman konfigürasyonlarında monte edildiğinde sistem düzeyinde doğrulamayı kapsar.

Çevresel uyum hususları, elektromanyetik performansın ötesine geçerek malzeme güvenliğini ve kullanım ömrünü tamamlamış ürünlerin bertaraf edilme gereksinimlerini de kapsar. Conta malzemeleri, etkili EMI koruması için gerekli olan performans özelliklerini korurken çevresel etkiyi en aza indirmek amacıyla dikkatle seçilmiştir. Her sevkiyatla birlikte sağlanan belgelerde, müşteri düzenleyici gereksinimlerini desteklemek amacıyla ilgili uyum sertifikaları ve malzeme güvenlik bilgileri yer almaktadır.

Özelleştirme ve Markalama Seçenekleri

Ağ ekipmanı üreticilerinin çeşitli gereksinimleri göz önünde bulundurularak, conta özelliklerini özel uygulama ihtiyaçlarına göre uyarlamak için kapsamlı özelleştirme imkanları sunulmaktadır. Özel boyutlar, kesit profilleri ve montaj konfigürasyonları, belirli ekipman tasarımları için performansı en iyi duruma getirmek üzere geliştirilebilir. Bu esneklik, ekipman üreticilerinin tasarım estetiği ile işlevsel gereksinimleri korurken üstün EMI koruması sağlamasına olanak tanır.

Malzeme özelleştirme seçenekleri, köpük yoğunluğu, iletken kumaş özellikleri ve çevre direnci karakteristiklerindeki farklılıkları içerir. Bu değişiklikler conta elemanının belirli çalışma ortamları veya performans gereksinimleri için optimize edilmesini sağlar. Zorlu ağ uygulamaları için gerekli olan güvenilirlik ve performans özelliklerinin korunmasını sağlamak üzere özelleştirme süreci boyunca mühendislik desteği mevcuttur.

Özel işaretleme veya tanımlama özellikleri gerektiren müşteriler için envanter yönetimi ve kalite kontrol prosedürlerini desteklemek amacıyla özel etiketleme ve ambalajlama seçenekleri sunulmaktadır. Bu hizmetler, müşteri teslim alma ve montaj süreçleriyle sorunsuz bir şekilde entegre olan ardışık numaralandırma, parti kodlaması veya özel ambalaj yapılandırmalarını içerebilir.

Küresel çapta faaliyet gösteren deneyimli bir metal ambalaj üreticisi olarak, kapsamlı özelleştirme yeteneklerimiz temel ürün değişikliklerinin ötesine geçerek, müşteri markalaşma ve pazar konumlandırma ihtiyaçlarını destekleyen tam OEM teneke ambalaj çözümlerini içerir. Bu entegre yaklaşım, müşterilerin depolama ve taşıma sırasında hassas conta malzemeleri için yeterli koruma sağlarken, ürünlerinin tutarlı bir imaj sergilemesini mümkün kılar.

Ambalaj ve Lojistik Desteği

Profesyonel ambalaj çözümleri, Dağıtım zinciri boyunca İletken Kumaşla Kaplanmış Köpük Contaların bütünlüğünü korur ve son kullanıcılar için kolay kullanım sağlar. Özel ambalaj malzemeleri, conta performansını etkileyebilecek sıkışma hasarı ve kontaminasyonu önler; açıkça etiketlenmiş kaplar ise etkili envanter yönetimi ve montaj süreçleri sağlar.

Ambalaj tasarımı, farklı conta konfigürasyonlarının kolayca tanımlanmasını ve işlenmesini sağlayan özellikler içerir ve böylece sistem performansını tehlikeye atan montaj hatalarının olasılığını azaltır. Nemin engellenmesi özelliği, depolama süresince köpük malzemenin sıkışma karakteristiklerini veya boyutsal stabilitesini etkileyebilecek çevre koşullarına karşı korunmasını sağlar.

Lojistik desteği, dünya çapındaki müşterilere güvenilir teslimatı sağlayan küresel dağıtım kapasitelerini kapsar. Uluslararası nakliye sağlayıcılarıyla kurulan ilişkiler, contaların taşınma sırasında sıcaklık ve nem kontrolünün korunarak verimli taşımacılığın yapılmasına olanak tanır. Takip sistemleri, sevkiyat durumuna ilişkin gerçek zamanlı görünürlük sağlayarak müşterilerin montaj programlarını koordine etmesini ve proje gecikmelerini en aza indirmesini mümkün kılar.

Büyük ölçekli projelerde önemli miktarda conta gerekebilir ve bu durumlarda özel lojistik çözümleri, müşterinin envanter yönetimini optimize ederken ihtiyaç duyulan zamanlarda malzemenin mevcut olmasını sağlayan kademeli teslimatlar, geçici depolama tesisleri ve tam zamanında teslimat programları içerebilir. Bu esnek lojistik düzenlemeleri, müşterilerin üretim takvimlerini sürdürürken aynı zamanda dönen sermaye gereksinimlerini en aza indirmelerine yardımcı olur.

Neden Bizi Seçmelisiniz

Hassas imalatta on yıllar süren deneyime sahip önde gelen özel tin kutu tedarikçisi konumumuz, kalite ve güvenilirliğin ön planda olduğu gelişmiş conta teknolojilerine doğal olarak uzanmaktadır. Metal malzemeler ve hassas imalat alanındaki bu kapsamlı geçmiş, modern ağ cihazlarının zorlu gereksinimlerini karşılayan etkili elektromanyetik koruma çözümleri oluşturma zorluklarına ilişkin benzersiz farkındalıklar sunar.

Uluslararası pazarlarda birden fazla kıtaya yayılmış varlığımız, tüm üretim tesislerinde tutarlı kalite standartlarını korurken yerel destek sunmamızı sağlar. Bu küresel bakış açısı, Ağ Ekipmanları için İletken Kumaşla Kaplanmış Köpük Contalarımızın farklı pazarlarda karşılaşılan çeşitli düzenleyici ve performans gereksinimlerini karşılamasını ve müşterilerin güvenilir bir metal ambalaj tedarikçisinden beklediği hızlı hizmeti sağlamasını garanti eder.

Sürekli iyileştirme konusundaki kararlılığımız, gelişmiş üretim teknolojilerine ve kalite kontrol sistemlerine yönelik sürekli yatırım yapmamızı teşvik eder. Mükemmellik konusundaki bu bağlılık, müşterilerin yalnızca mevcut gereksinimleri karşılayan değil, aynı zamanda ağ ekipmanları tasarımındaki geleceğin teknolojik gelişmelerine uyum sağlayacak şekilde tasarlanmış ürünleri almasını sağlar. Önde gelen ekipman üreticileriyle yapılan düzenli iş birlikleri, ortaya çıkan gereksinimler ve teknoloji trendleri hakkında değerli içgörüler sunar.

Teknik destek imkanları, özel uygulamalar için kapsamlı mühendislik desteği, montaj kılavuzu ve performans optimizasyonu önerilerini içerir. Deneyimli teknik ekibimiz, müşterilerle yakından çalışarak conta çözümlerinin başarılı bir şekilde uygulanmasını sağlarken ürün ömrü boyunca devam eden destek sunar. Bu iş birliğine dayalı yaklaşım, müşterilerin en iyi sonuçlara ulaşmalarına yardımcı olurken geliştirme süresini ve maliyeti en aza indirir.

Sonuç

Ağ Ekipmanları için İletken Kumaşlı Köpük Conta, modern ağ sistemlerinin karşı karşıya olduğu karmaşık elektromanyetik girişim sorunlarına gelişmiş bir çözüm sunar. Esnek köpük alt tabanlarla yüksek performanslı iletken kumaşların yenilikçi kombinasyonu sayesinde bu conta teknolojisi, üstün koruma etkinliği sağlarken aynı zamanda güvenilir uzun vadeli çalışma için gerekli mekanik özelliklerini korur. Geniş özelleştirme seçenekleri yelpazesi, titiz kalite kontrol süreçleri ve küresel lojistik desteği, müşterilerin kendilerine özel gereksinimlerine tam olarak uygun çözümler almasını garanti eder. Ağ teknolojisi gelişmeye devam ettikçe ve elektromanyetik girişim zorlukları giderek daha karmaşık hâle geldikçe, bu gelişmiş conta teknolojisi, kritik iletişim altyapısını korumak ve küresel bağlantı çözümlerinin sürekli ilerlemesini desteklemek için gerekli performans, güvenilirlik ve esnekliği sağlar.

Profesyonel EMI Koruma Bantları - RFI/ESD Koruması İçin Tam Çözüm

Mükemmel ekran performansı |

Geniş bir frekans aralığında yüksek koruma etkinliği sunar, EMI, RFI ve ESD tam koruması için idealdir. |

||||||

Yüksek İletkenlik & Düşük Direnç |

Nikel/bakır kaplı kumaş veya saf bakır folyo gibi üstün malzemelerden üretilmiştir ve iyi elektrik iletkenliği sağlar ve güvenilir topraklamayı garanti eder. |

||||||

Esnek ve Şekle Uygun |

Ultra ince, esnek ve hafif tasarım, iç devre kartları ve esnek devreler gibi kıvrımlı yüzeylere ve dar alanlara kolayca uygulanmasını sağlar. devre kartları ve esnek devreler. |

||||||

Özelleştirilebilir Çözümler |

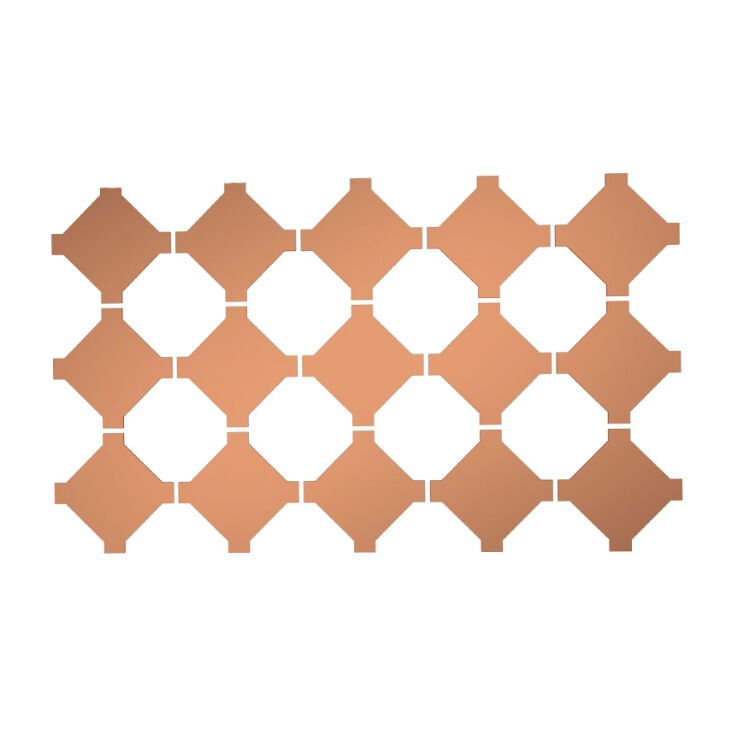

Özel boyutlarda, şekillerde ve die-cut (OEM/ODM desteklenir) olarak temin edilebilir. Küresel çevre standartlarına uyum için RoHS ve REACH uyumlu. standartları. |

||||||

Tüketici Elektroniği |

Akıllı telefonlar, dizüstü bilgisayarlar, oyun konsolları, LCD ekranlar ve 5G kablosuz şarj cihazları için iç devre kartı koruması ve yüksek hızlı HDMI sinyal koruması. |

||||||

Otomotiv & Ulaşım |

Otomotiv elektroniği, otonom araçlar LiDAR/Radar sistemleri ve güçlü EMC çözümlerinin bir parçası olarak EV kablosuz şarj cihazları. |

||||||

Telekom & Ağ |

Ağ ekipmanları, 5G altyapısı ve dolap koruması sinyal bütünlüğünü sağlamak ve girişimi önlemek için. |

||||||

Sanayi ve Tıp

|

Talep eden endüstriyel kontrol sistemleri, güç kaynakları ve hassas tıbbi elektronik cihazlar güvenilir performans gerektirir koşullar. |

||||||

Mevcut türleri

Şirket Profili

Tüketici elektroniği, iletişim ağları ve yeni enerji araçları sektörlerine öncelikle hizmet veriyoruz. Kaliteye ve inovasyona olan bağlılığımızı desteklemek için dört stratejik konumda ulusal bir üretim tesisi kurduk:

1. Şenzhen'de 1.000 metrekarelik yeni malzeme formülü Ar-Ge merkezi.

2. Dongguan'da 2.000 metrekarelik yenilikçi topraklama sarma üretim tesisi.

3. Hunan'da 10.000 metrekarelik iletken elektromanyetik koruma bant kaplama tesisi.

4. Shandong'da 1.000 metrekarelik magnetron sputter ile sürekli altın/kalay kaplama tesisi.

Kaplamacılık, sırlama ve işleme yeteneklerini sunan Çin'deki tek dikey entegre edilmiş entegratör olarak, malzeme endüstrisi zincirinde öncü bir inovatör ve temel değer sağlayıcısı olmayı amaçlıyoruz. Nihai hedefimiz, müşterilerimizin zorluklarını çözmeleri için uzun vadeli güvenilir çözüm sağlayıcısı ve ortağı olmaktır.

İcat Patenti

Sistem sertifikasyonu

SSS

Çin'in Guangdong eyaletinde bulunuyoruz, 2011 yılından beri faaliyet gösteriyoruz ve Güney Asya'ya satıyoruz (%10,00). Ofisimizde yaklaşık 101-200 kişi bulunmaktadır.

2. kalitemizi nasıl garanti edebiliriz?

Toplu üretimden önce her zaman bir ön üretim örneği yaparız;

Gönderimedan önce her zaman son denetim yapılır;

3. bizden ne satın alabilirsiniz?

Koruyucu bant, Yapışkanlı bantlar, Su geçirmez ve nefes alan membran, Özel üretim, Ham madde die-cutting

4. neden bizden satın almalısınız, diğer tedarikçilerden değil?

Shenzhen Johan Material Tech Co., Ltd. 2011 yılında kurulmuştur ve inovatif bir ulusal yüksek teknoloji işletmesidir.

elektronik endüstrisi için yenilikçi EMC (elektromanyetik uyumluluk) topraklama elastomerleri ve özelleştirilmiş bant çözümleri

5. hangi hizmetleri sunabiliriz?

Kabul edilen teslimat şartları: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Kabul edilen ödeme para birimi: USD,EUR,JPY,CAD,AUD,HKD,GBP,Cny,CHF;

Kabul Edilen Ödeme Türü: T/T,L/C,D/P D/A,MoneyGram,Kredi Kartı,PayPal,Western Union,Nakit,Escrow;

Konuşulan dil: İngilizce,Çin