Introduction

In today's rapidly evolving electronics industry, electromagnetic interference protection has become a critical concern for manufacturers worldwide. The Low Compression Set Conductive Sponge Foam for Display Shielding represents a breakthrough solution designed to address the complex challenges of electronic device protection while maintaining optimal performance characteristics. This advanced material combines superior conductivity properties with exceptional durability, making it an indispensable component for electronics manufacturers seeking reliable EMI shielding solutions. The foam's unique composition ensures consistent performance across various environmental conditions while providing the flexibility needed for modern display applications.

As electronic devices become increasingly sophisticated and compact, the need for effective electromagnetic shielding continues to grow. This specialized conductive foam addresses these evolving requirements by offering a perfect balance between mechanical properties and electrical performance. The material's innovative design allows it to maintain its protective capabilities even under repeated compression cycles, ensuring long-term reliability in demanding applications.

Product Overview

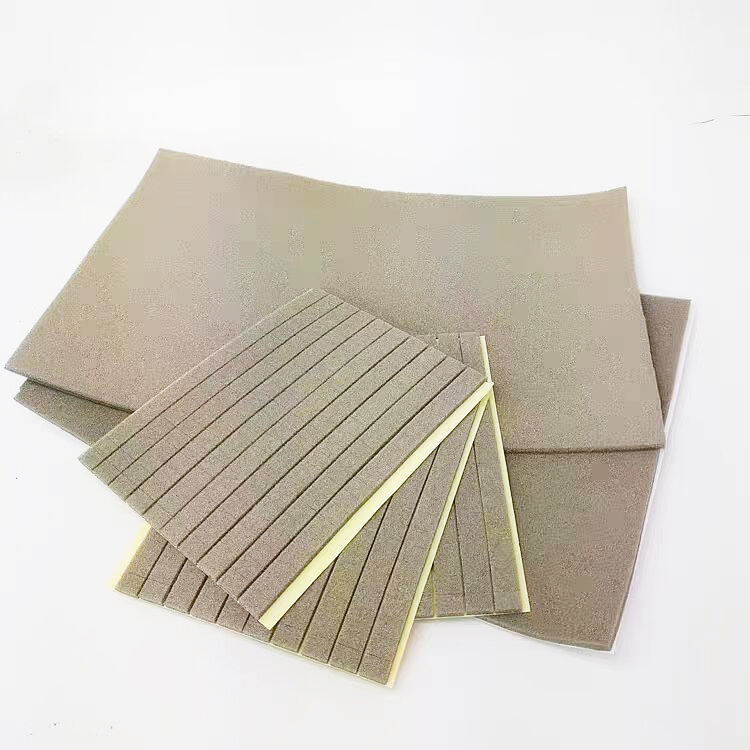

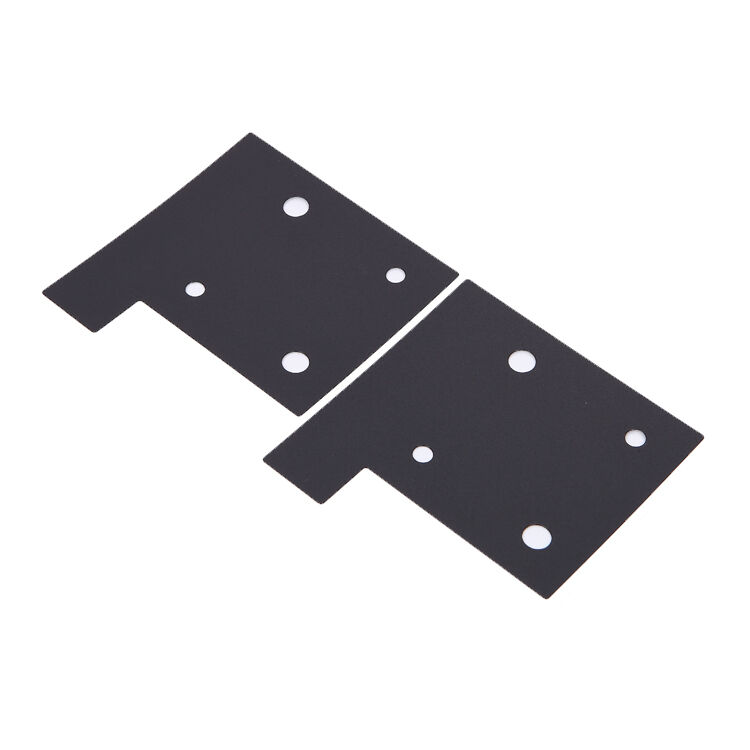

The Low Compression Set Conductive Sponge Foam for Display Shielding is engineered using advanced polymer science and conductive filler technology to create a material that excels in both electrical and mechanical performance. This specialized foam features a carefully controlled cellular structure that provides optimal compression characteristics while maintaining excellent conductivity throughout its service life. The material's unique formulation incorporates high-quality conductive particles that are uniformly distributed throughout the foam matrix, ensuring consistent shielding effectiveness across the entire surface area.

The foam's cellular architecture is specifically designed to provide superior resilience and recovery properties, making it ideal for applications where repeated compression and decompression cycles are common. This characteristic is particularly valuable in display shielding applications where the foam must maintain its sealing properties over extended periods while accommodating thermal expansion and contraction of electronic components. The material's advanced composition also provides excellent chemical resistance, ensuring compatibility with various cleaning agents and environmental conditions commonly encountered in electronic device manufacturing.

Features & Benefits

Superior Compression Recovery

The exceptional compression set properties of this conductive foam ensure that it maintains its original thickness and sealing capabilities even after prolonged compression. This characteristic is achieved through advanced polymer chemistry that creates a resilient cellular structure capable of withstanding thousands of compression cycles without significant permanent deformation. The foam's ability to recover to its original dimensions ensures consistent EMI shielding performance throughout the product's lifecycle, reducing the need for frequent replacements and maintenance.

Outstanding Electrical Conductivity

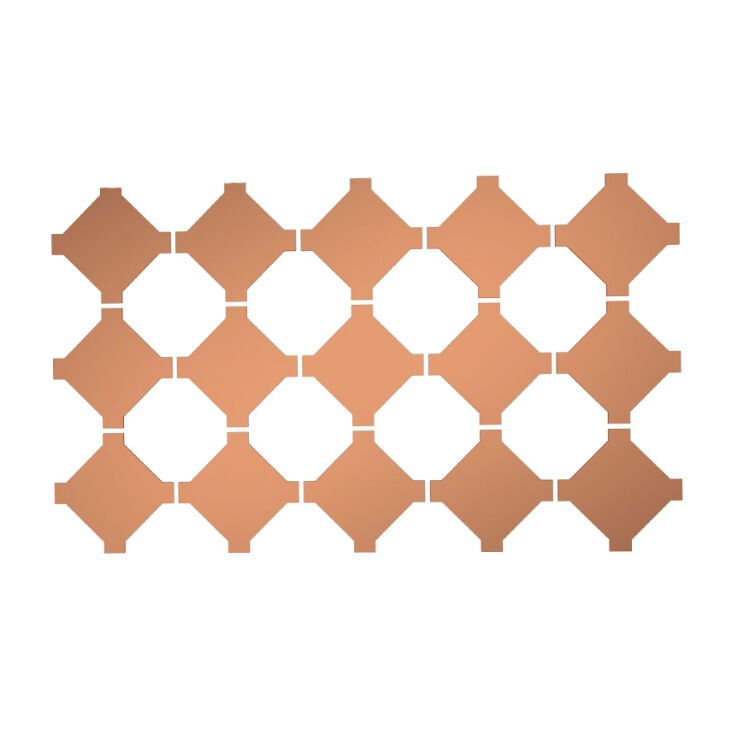

The foam incorporates premium conductive fillers that create multiple conductive pathways throughout the material structure. This design ensures reliable electrical continuity and effective electromagnetic shielding across a broad frequency spectrum. The conductive network remains stable even under mechanical stress, maintaining consistent shielding effectiveness in dynamic applications where the foam experiences regular movement or vibration.

Enhanced Environmental Stability

Engineered to perform reliably across a wide range of environmental conditions, this Low Compression Set Conductive Sponge Foam for Display Shielding demonstrates exceptional stability when exposed to temperature fluctuations, humidity variations, and common industrial chemicals. The material's resistance to environmental degradation ensures long-term performance reliability, making it suitable for both indoor and outdoor electronic applications where environmental exposure is a concern.

Applications & Use Cases

The versatility of this conductive foam makes it suitable for a diverse range of electronic shielding applications. In display technology, the foam serves as an essential component for protecting sensitive electronic circuits from electromagnetic interference while providing effective sealing against dust and moisture ingress. The material's excellent compression properties make it particularly well-suited for applications in portable electronic devices where space constraints require materials that can function effectively in confined spaces.

Telecommunications equipment manufacturers utilize this foam for cabinet shielding applications where consistent EMI protection is critical for maintaining signal integrity. The foam's ability to maintain its sealing properties under varying environmental conditions makes it ideal for outdoor communication equipment that must perform reliably in challenging weather conditions. Additionally, the material's excellent compression recovery ensures that EMI gaskets maintain their effectiveness even after repeated equipment servicing and maintenance operations.

In automotive electronics applications, the Low Compression Set Conductive Sponge Foam for Display Shielding provides essential protection for dashboard displays and infotainment systems. The material's resistance to temperature extremes and vibration makes it particularly valuable in automotive environments where electronic components must withstand harsh operating conditions while maintaining reliable performance. The foam's ability to conform to irregular surfaces ensures effective sealing around complex electronic assemblies commonly found in modern vehicles.

Quality Control & Compliance

Manufacturing processes for this advanced conductive foam incorporate rigorous quality control measures to ensure consistent material properties and performance characteristics. Each production batch undergoes comprehensive testing protocols that evaluate electrical conductivity, compression set resistance, and environmental stability. These quality assurance procedures ensure that every shipment meets the stringent requirements of modern electronics manufacturing while maintaining the high standards expected by international customers.

The material is produced in accordance with internationally recognized standards for electronic materials, ensuring compatibility with global manufacturing processes and regulatory requirements. Environmental compliance is maintained through careful selection of raw materials and manufacturing processes that minimize environmental impact while delivering superior product performance. The foam's composition is designed to meet the evolving requirements of electronic device manufacturers who prioritize both performance and environmental responsibility in their material selection processes.

Customization & Branding Options

Understanding that different applications require specific material characteristics, comprehensive customization options are available for the Low Compression Set Conductive Sponge Foam for Display Shielding. Material thickness, density, and conductivity levels can be tailored to meet precise application requirements, ensuring optimal performance in specialized electronic applications. Custom die-cutting services enable the production of complex shapes and configurations that match specific design requirements, eliminating the need for secondary processing operations.

Surface treatments and adhesive backing options can be incorporated to simplify installation processes and enhance bonding characteristics with various substrate materials. These customization capabilities allow electronics manufacturers to integrate the foam seamlessly into their existing manufacturing processes while maintaining production efficiency. Special packaging configurations can also be arranged to accommodate specific handling and storage requirements, ensuring that the material arrives at manufacturing facilities in optimal condition for immediate use.

Packaging & Logistics Support

Professional packaging solutions ensure that the conductive foam maintains its properties during transportation and storage. Specialized protective packaging prevents compression damage during shipping while protecting the material from environmental contamination that could affect its performance characteristics. The packaging design accommodates various shipment sizes and configurations, providing flexibility for both large-scale production requirements and smaller prototype quantities.

Comprehensive logistics support includes coordination with international freight services to ensure reliable delivery schedules that align with customer production requirements. Documentation packages include detailed material specifications and handling instructions that facilitate smooth integration into customer quality control and manufacturing processes. The logistics infrastructure is designed to support global distribution while maintaining the integrity and quality of the Low Compression Set Conductive Sponge Foam for Display Shielding throughout the supply chain.

Why Choose Us

Our company brings decades of experience in advanced material development and manufacturing to the electronics industry, serving customers across multiple continents with innovative solutions that address the evolving challenges of modern electronics manufacturing. This extensive experience in international markets has enabled us to develop comprehensive understanding of diverse customer requirements and regulatory environments, ensuring that our products meet the highest standards of quality and performance expected by global electronics manufacturers.

As a recognized metal packaging supplier and materials technology leader, our expertise extends beyond individual products to encompass complete solution development and technical support services. Our collaboration with electronics manufacturers worldwide has resulted in continuous product improvement and innovation, ensuring that our Low Compression Set Conductive Sponge Foam for Display Shielding incorporates the latest advances in material science and manufacturing technology. This commitment to excellence and innovation has established our reputation as a trusted partner for premium electronic materials and custom packaging solutions.

Conclusion

The Low Compression Set Conductive Sponge Foam for Display Shielding represents the pinnacle of electromagnetic interference protection technology, combining superior mechanical properties with outstanding electrical performance in a single, versatile material solution. Its exceptional compression recovery characteristics, reliable conductivity, and environmental stability make it an ideal choice for demanding electronic applications where long-term performance and reliability are essential. The material's adaptability to various customization requirements and its compatibility with modern manufacturing processes ensure that it can meet the diverse needs of electronics manufacturers worldwide, from portable devices to industrial equipment applications. This advanced foam solution continues to set new standards for EMI shielding materials, providing electronics manufacturers with the confidence and performance they need to develop next-generation electronic products that excel in today's competitive marketplace.

Professional EMI Shielding Tapes - Total Solution for RFI/ESD Protection

Excellent Shielding Performance |

Offers high shielding effectiveness over a wide frequency range, ideal for EMI, RFI, and ESD full protection. |

||||||

High Conductivity & Low Resistance |

Made from superior materials like nickel/copper coated fabric or pure copper foil, ensuring good electrical conductivity and reliable grounding. |

||||||

Flexible & Conformable |

Ultra-thin, flexible, and lightweight design allows for easy application on curved surfaces and tight spaces, such as internal circuit boards and flexible circuits. |

||||||

Customizable Solutions |

Available in custom sizes, shapes, and die-cuts (OEM/ODM supported). RoHS and REACH compliant to meet global environmental standards. |

||||||

Consumer Electronics |

Smartphones, laptops, gaming consoles, LCD displays, and 5G wireless chargers for internal circuit board shielding and high-speed HDMI signal protection. |

||||||

Automotive & Transportation |

Automotive electronics, autonomous vehicles LiDAR/Radar systems, and EV wireless chargers as part of robust EMC solutions. |

||||||

Telecom & Networking |

Networking equipment, 5G infrastructure, and cabinet shielding to ensure signal integrity and prevent interference. |

||||||

Industrial & Medical

|

Industrial control systems, power supplies, and sensitive medical electronic devices requiring reliable performance in demanding conditions. |

||||||

Available Types

Company Profile

We cater primarily to the consumer electronics, communication networks, and emerging energy vehicle sectors. To back ourcommitment to quality and innovation, we have established a national production base across four strategic locations:

1. A 1,000-square-meter new material formula R&D center in Shenzhen.

2. A 2,000-square-meter innovative grounding wrapping production plant in Dongguan.

3. A 10,000-square-meter conductive shielding tape coating plant in Hunan.

4. A 1,000-square-meter magnetron sputtering continuous gold/tin plating plant in Shandong.

As the only vertically integrated integrator in China offering electroplating, coating, and processing capabilities, we strive to become a leading innovator and provider of core values within the materials industry chain. Our ultimate goal is to be a long-term trusted solution provider and partner for our customers in addressing their challenges.

Invention Patent

System certification

FAQ

We are based in Guangdong, China, start from 2011,sell to South Asia(10.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Shielding tape,Adhesive tapes,Waterproof and breathable membrane,Customized production,Raw material die-cutting

4. why should you buy from us not from other suppliers?

Shenzhen Johan Material Tech Co., Ltd. was established in 2011, and is an innovative national high-tech enterprise providing

innovative EMC (electromagnetic compatibility) grounding elastomers and customized tape solutions for the electronics indus

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency: USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken: English,Chinese