Introduction

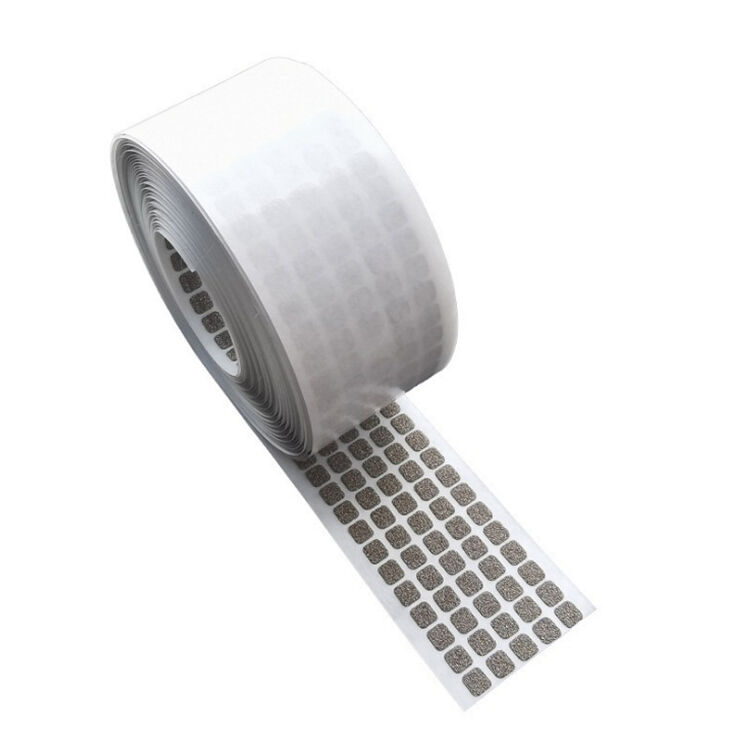

In today's rapidly evolving electronics landscape, protecting high-speed signal integrity has become paramount for manufacturers across telecommunications, aerospace, and industrial sectors. The Flexible Conductive Sponge Gasket for High Speed Signal Protection represents a breakthrough solution engineered to address the most demanding electromagnetic interference challenges while maintaining superior flexibility and reliability. This innovative gasket technology combines advanced conductive materials with specialized sponge architecture to create an effective barrier against signal disruption, ensuring optimal performance in critical electronic applications.

As electronic devices continue to operate at increasingly higher frequencies, traditional shielding methods often fall short of providing adequate protection while accommodating the complex geometries and thermal expansion requirements of modern equipment. The flexible conductive sponge gasket bridges this gap by offering exceptional conformability to irregular surfaces while maintaining consistent electrical conductivity across varying environmental conditions.

Product Overview

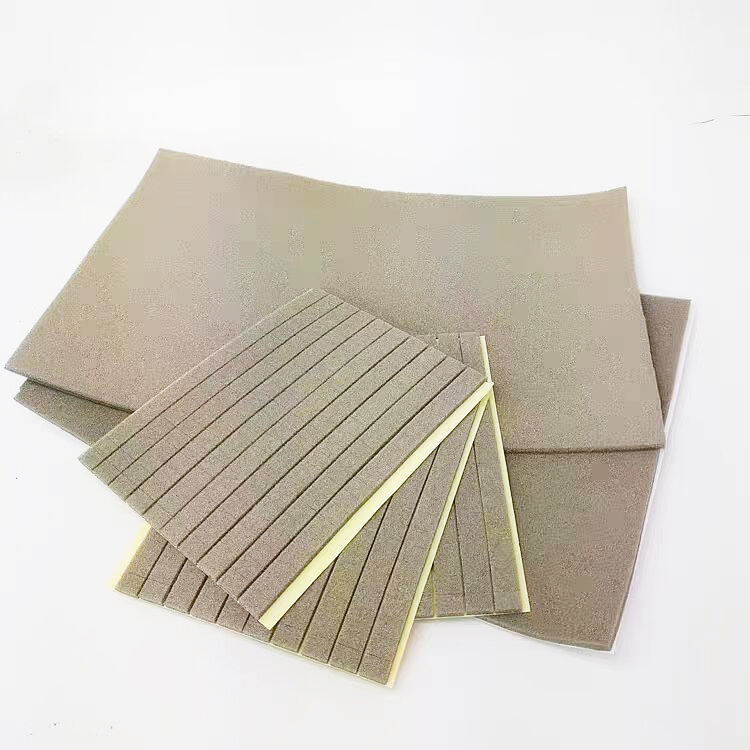

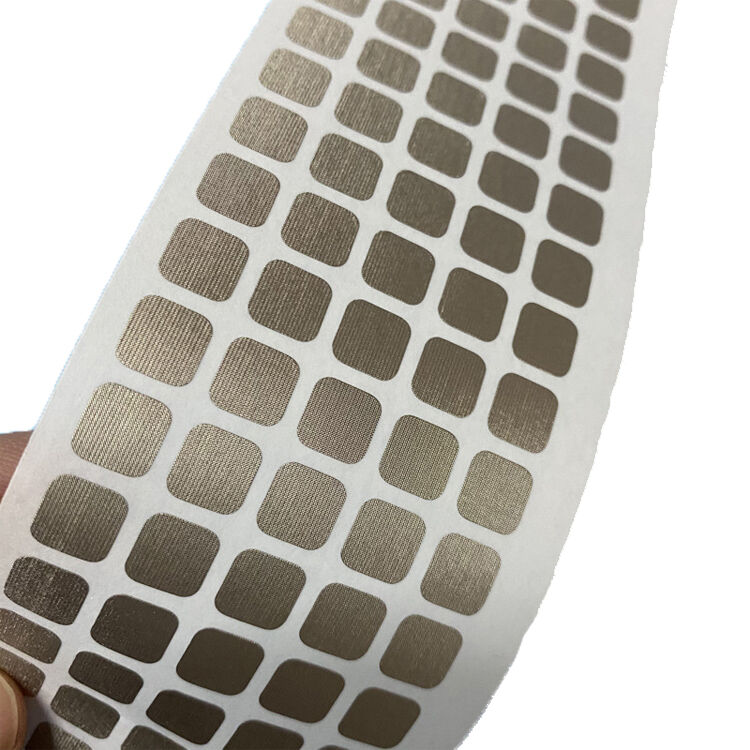

The Flexible Conductive Sponge Gasket for High Speed Signal Protection stands as a sophisticated electromagnetic interference shielding solution designed specifically for applications requiring both superior signal protection and mechanical flexibility. This gasket utilizes a proprietary foam substrate infused with carefully selected conductive particles to achieve optimal shielding effectiveness across a broad frequency spectrum while maintaining the compressibility and resilience essential for dynamic applications.

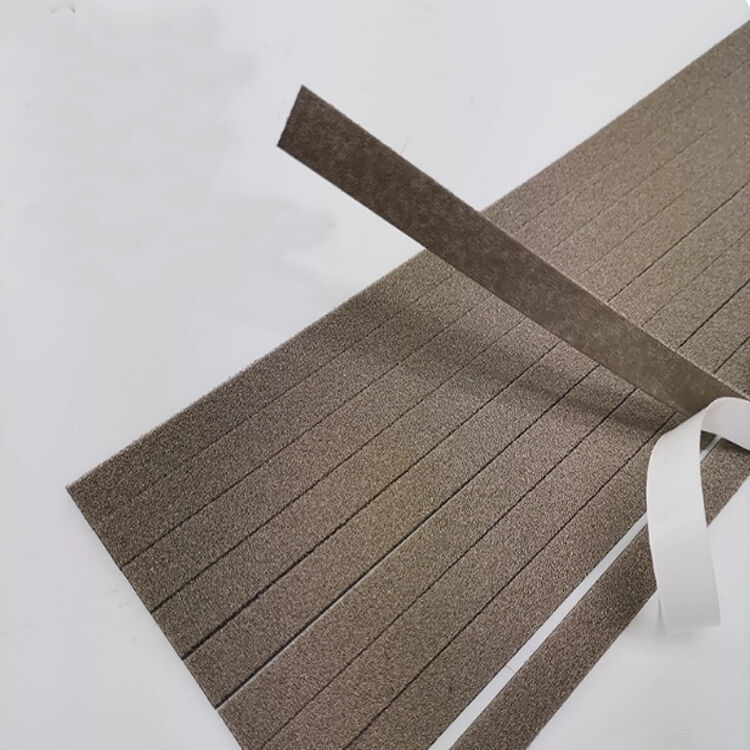

Manufactured using advanced polymer chemistry and precision coating techniques, this gasket material demonstrates exceptional performance characteristics that make it suitable for both commercial and military-grade applications. The unique cellular structure provides consistent compression recovery while the conductive coating ensures reliable electrical contact even under repeated compression cycles. The gasket maintains its protective properties across wide temperature ranges and various humidity conditions, making it an ideal choice for outdoor installations and harsh industrial environments.

Features & Benefits

Superior Electromagnetic Shielding Performance

The flexible conductive sponge gasket delivers exceptional electromagnetic interference attenuation across multiple frequency bands, effectively protecting sensitive electronic circuits from both conducted and radiated interference. The carefully engineered conductive particle distribution ensures uniform shielding effectiveness while the flexible substrate maintains intimate contact with mating surfaces, eliminating potential leakage paths that could compromise signal integrity.

Enhanced Mechanical Flexibility

Unlike rigid metallic shielding solutions, this gasket material offers remarkable conformability to complex geometries and surface irregularities. The sponge structure provides excellent compression characteristics, allowing the gasket to accommodate manufacturing tolerances while maintaining consistent electrical performance. This flexibility significantly reduces installation complexity and enables reliable sealing in applications where thermal expansion and mechanical vibration are primary concerns.

Long-Term Reliability

Engineered for extended service life, the Flexible Conductive Sponge Gasket for High Speed Signal Protection demonstrates superior resistance to environmental degradation, including ultraviolet exposure, chemical corrosion, and temperature cycling. The robust polymer matrix protects the conductive elements from oxidation while maintaining structural integrity under repeated compression and release cycles, ensuring consistent performance throughout the product lifecycle.

Applications & Use Cases

The versatile nature of the flexible conductive sponge gasket makes it suitable for an extensive range of electromagnetic shielding applications across diverse industries. In telecommunications infrastructure, these gaskets provide essential protection for base station equipment, fiber optic enclosures, and network switching cabinets where high-frequency signal integrity is critical for reliable communication networks.

Aerospace and defense applications benefit significantly from the gasket's ability to provide consistent shielding performance under extreme environmental conditions. Military radar systems, avionics equipment, and satellite communication devices rely on this technology to maintain operational effectiveness in challenging electromagnetic environments while meeting stringent reliability requirements.

Medical device manufacturers utilize these gaskets in diagnostic imaging equipment, patient monitoring systems, and laboratory instrumentation where electromagnetic compatibility is essential for accurate measurements and patient safety. The biocompatible materials and non-outgassing properties make the gaskets suitable for sensitive medical environments without compromising performance or safety standards.

Industrial automation systems, including programmable logic controllers, variable frequency drives, and robotic control systems, depend on effective electromagnetic shielding to prevent interference from high-power machinery and switching equipment. The flexible gasket design accommodates the dynamic mounting requirements of industrial equipment while providing reliable protection against electromagnetic disturbances.

Quality Control & Compliance

Manufacturing processes for the Flexible Conductive Sponge Gasket for High Speed Signal Protection adhere to rigorous quality management systems that ensure consistent product performance and reliability. Comprehensive testing protocols evaluate electromagnetic shielding effectiveness, mechanical properties, and environmental resistance throughout the production process, guaranteeing that each gasket meets exacting performance specifications.

The gasket materials comply with international standards for electromagnetic compatibility and environmental safety, including restrictions on hazardous substances and conflict minerals regulations. Advanced analytical techniques verify material purity and composition while accelerated aging tests confirm long-term stability under various environmental conditions.

Quality assurance procedures encompass incoming material inspection, in-process monitoring, and final product validation to maintain consistent quality standards. Statistical process control methods track critical parameters throughout manufacturing, enabling continuous improvement and ensuring optimal product performance for demanding applications.

Customization & Branding Options

Understanding that different applications require specific performance characteristics and dimensional requirements, comprehensive customization capabilities enable the development of tailored solutions for unique electromagnetic shielding challenges. Engineering teams work closely with customers to optimize gasket formulations, compression characteristics, and geometric configurations to meet specific application requirements.

Custom gasket configurations can accommodate complex shapes, multiple compression zones, and integrated mounting features to simplify installation and improve overall system performance. Specialized coating formulations provide enhanced performance for specific frequency ranges or environmental conditions, ensuring optimal shielding effectiveness for targeted applications.

Private labeling and custom packaging options support brand recognition and inventory management requirements for distributors and system integrators. Technical documentation and certification packages can be customized to support customer qualification processes and regulatory compliance requirements across different markets and applications.

Packaging & Logistics Support

Comprehensive packaging solutions protect gasket materials during transportation and storage while facilitating efficient handling and installation processes. Protective packaging materials prevent contamination and mechanical damage while maintaining material properties throughout the supply chain. Custom packaging configurations support various order quantities and delivery schedules to meet diverse customer requirements.

Flexible logistics capabilities accommodate both standard and expedited delivery schedules while maintaining product quality and integrity. Strategic inventory management ensures reliable product availability while specialized handling procedures protect sensitive gasket materials from environmental exposure and mechanical damage during transit.

Technical support documentation accompanies shipments to provide installation guidance, handling recommendations, and storage requirements. Detailed material certificates and test reports ensure traceability and support customer quality management systems while facilitating smooth integration into manufacturing processes.

Why Choose Us

With decades of experience in advanced materials engineering and electromagnetic compatibility solutions, our company has established a reputation as a trusted metal packaging manufacturer and specialized gasket supplier serving global markets across multiple industries. Our comprehensive understanding of electromagnetic shielding challenges enables us to provide innovative solutions that exceed performance expectations while maintaining cost-effectiveness.

Our international presence and extensive industry expertise position us as a preferred custom tin box supplier and electromagnetic shielding partner for companies requiring reliable, high-performance gasket solutions. Collaborative relationships with leading electronics manufacturers, aerospace companies, and telecommunications providers have refined our capabilities and expanded our technical knowledge base.

Advanced manufacturing facilities and rigorous quality management systems ensure consistent product performance while flexible production capabilities accommodate both standard and custom requirements. Our commitment to continuous innovation drives ongoing development of enhanced materials and manufacturing processes that address evolving market needs and technological challenges.

Conclusion

The Flexible Conductive Sponge Gasket for High Speed Signal Protection represents a significant advancement in electromagnetic shielding technology, combining superior performance characteristics with the flexibility and reliability demanded by modern electronic applications. Its unique combination of effective signal protection, mechanical adaptability, and long-term durability makes it an essential component for manufacturers seeking to ensure optimal electromagnetic compatibility in increasingly complex electronic systems. The comprehensive customization capabilities, rigorous quality standards, and extensive application versatility position this gasket solution as a cornerstone technology for protecting critical electronic infrastructure across diverse industries and challenging environments.

Professional EMI Shielding Tapes - Total Solution for RFI/ESD Protection

Excellent Shielding Performance |

Offers high shielding effectiveness over a wide frequency range, ideal for EMI, RFI, and ESD full protection. |

||||||

High Conductivity & Low Resistance |

Made from superior materials like nickel/copper coated fabric or pure copper foil, ensuring good electrical conductivity and reliable grounding. |

||||||

Flexible & Conformable |

Ultra-thin, flexible, and lightweight design allows for easy application on curved surfaces and tight spaces, such as internal circuit boards and flexible circuits. |

||||||

Customizable Solutions |

Available in custom sizes, shapes, and die-cuts (OEM/ODM supported). RoHS and REACH compliant to meet global environmental standards. |

||||||

Consumer Electronics |

Smartphones, laptops, gaming consoles, LCD displays, and 5G wireless chargers for internal circuit board shielding and high-speed HDMI signal protection. |

||||||

Automotive & Transportation |

Automotive electronics, autonomous vehicles LiDAR/Radar systems, and EV wireless chargers as part of robust EMC solutions. |

||||||

Telecom & Networking |

Networking equipment, 5G infrastructure, and cabinet shielding to ensure signal integrity and prevent interference. |

||||||

Industrial & Medical

|

Industrial control systems, power supplies, and sensitive medical electronic devices requiring reliable performance in demanding conditions. |

||||||

Available Types

Company Profile

We cater primarily to the consumer electronics, communication networks, and emerging energy vehicle sectors. To back ourcommitment to quality and innovation, we have established a national production base across four strategic locations:

1. A 1,000-square-meter new material formula R&D center in Shenzhen.

2. A 2,000-square-meter innovative grounding wrapping production plant in Dongguan.

3. A 10,000-square-meter conductive shielding tape coating plant in Hunan.

4. A 1,000-square-meter magnetron sputtering continuous gold/tin plating plant in Shandong.

As the only vertically integrated integrator in China offering electroplating, coating, and processing capabilities, we strive to become a leading innovator and provider of core values within the materials industry chain. Our ultimate goal is to be a long-term trusted solution provider and partner for our customers in addressing their challenges.

Invention Patent

System certification

FAQ

We are based in Guangdong, China, start from 2011,sell to South Asia(10.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Shielding tape,Adhesive tapes,Waterproof and breathable membrane,Customized production,Raw material die-cutting

4. why should you buy from us not from other suppliers?

Shenzhen Johan Material Tech Co., Ltd. was established in 2011, and is an innovative national high-tech enterprise providing

innovative EMC (electromagnetic compatibility) grounding elastomers and customized tape solutions for the electronics indus

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency: USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken: English,Chinese