Introduction

In today's rapidly evolving electronics industry, electromagnetic interference presents significant challenges for manufacturers seeking to maintain signal integrity and ensure reliable device performance. The Copper Foil Tape Conductive Adhesive for EMI Shielding and Electrical Grounding emerges as an essential solution for professionals who demand superior electromagnetic compatibility and robust electrical connections. This advanced conductive tape combines the natural conductivity properties of copper with specialized adhesive technology to deliver exceptional shielding effectiveness across diverse electronic applications.

Modern electronic devices operate in increasingly complex electromagnetic environments, where unwanted interference can compromise functionality and regulatory compliance. Our copper foil tape represents a critical component in the arsenal of electromagnetic shielding solutions, offering engineers and manufacturers a reliable method to protect sensitive circuits while establishing effective grounding pathways. The product addresses the growing need for versatile shielding materials that can adapt to various form factors and installation requirements without compromising performance or durability.

Product Overview

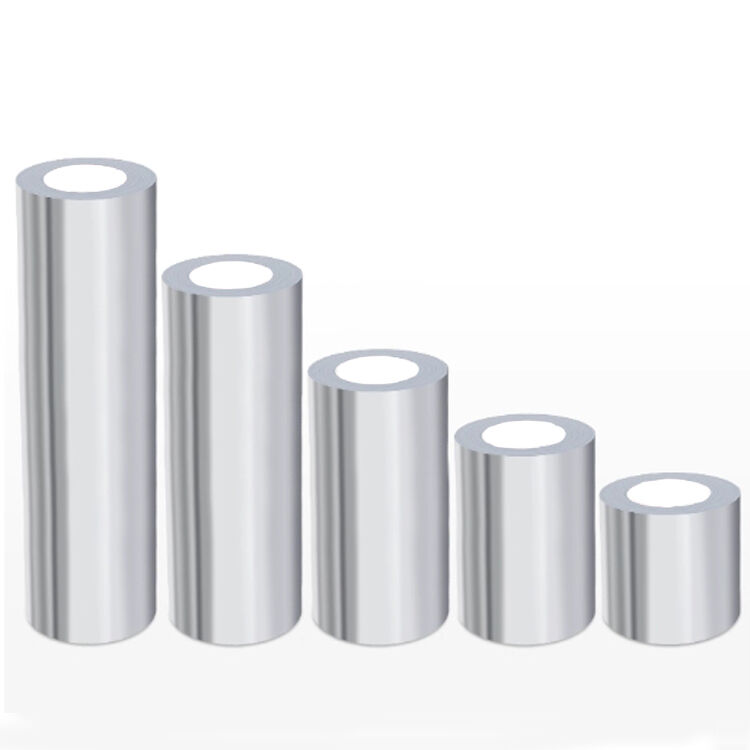

The Copper Foil Tape Conductive Adhesive for EMI Shielding and Electrical Grounding features a meticulously engineered construction designed to maximize electromagnetic shielding performance while maintaining ease of application. The tape consists of high-purity copper foil backing combined with a specialized conductive adhesive that ensures consistent electrical continuity across the entire bonded surface. This dual-layer construction creates an effective barrier against electromagnetic radiation while simultaneously providing a reliable electrical connection pathway.

The copper foil substrate exhibits excellent malleability, allowing the tape to conform seamlessly to irregular surfaces and complex geometries commonly encountered in electronic enclosures and cable assemblies. The conductive adhesive formulation maintains its electrical properties across a wide temperature range, ensuring consistent performance in demanding environmental conditions. This combination of materials creates a versatile shielding solution that addresses both electromagnetic interference suppression and electrical grounding requirements in a single, easy-to-apply product.

Manufacturing precision ensures uniform thickness and consistent adhesive distribution, resulting in predictable shielding effectiveness and reliable electrical performance. The tape's construction incorporates advanced materials science to balance conductivity requirements with practical application considerations, making it suitable for both automated production processes and manual installation procedures.

Features & Benefits

Superior Electromagnetic Shielding Performance

The copper foil construction delivers exceptional electromagnetic shielding effectiveness across a broad frequency spectrum, making the Copper Foil Tape Conductive Adhesive for EMI Shielding and Electrical Grounding particularly valuable for applications requiring reliable protection against radio frequency interference. The inherent properties of copper provide excellent attenuation characteristics, effectively blocking unwanted electromagnetic energy from penetrating sensitive electronic circuits and components.

The shielding performance remains consistent across various environmental conditions, ensuring reliable protection throughout the product's operational lifetime. This consistency stems from the stable electrical properties of the copper foil and the robust adhesive bond that maintains surface contact integrity over time. The tape's ability to maintain shielding effectiveness under mechanical stress and temperature fluctuations makes it particularly suitable for demanding applications where long-term reliability is paramount.

Conductive Adhesive Technology

The specialized conductive adhesive represents a significant advancement in tape technology, providing both mechanical bonding and electrical continuity in a single application. This adhesive maintains low electrical resistance across the bonded interface, ensuring effective electrical grounding and signal continuity. The formulation resists degradation from environmental factors while maintaining its conductive properties throughout extended service periods.

The adhesive's conductive matrix eliminates the need for additional grounding mechanisms in many applications, simplifying installation procedures and reducing overall system complexity. This integrated approach to conductivity and adhesion provides cost-effective solutions for manufacturers seeking to streamline their electromagnetic compatibility implementations while maintaining superior performance standards.

Versatile Application Characteristics

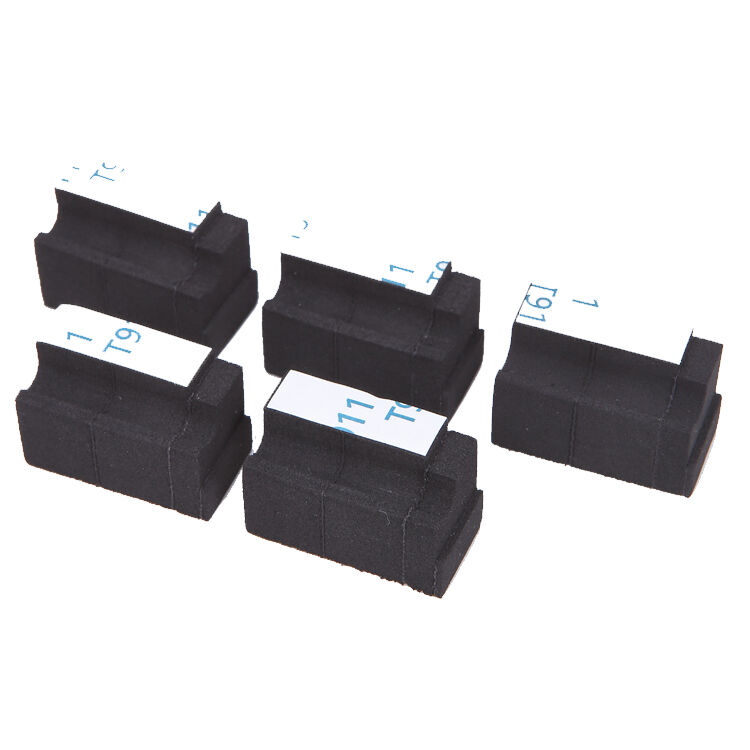

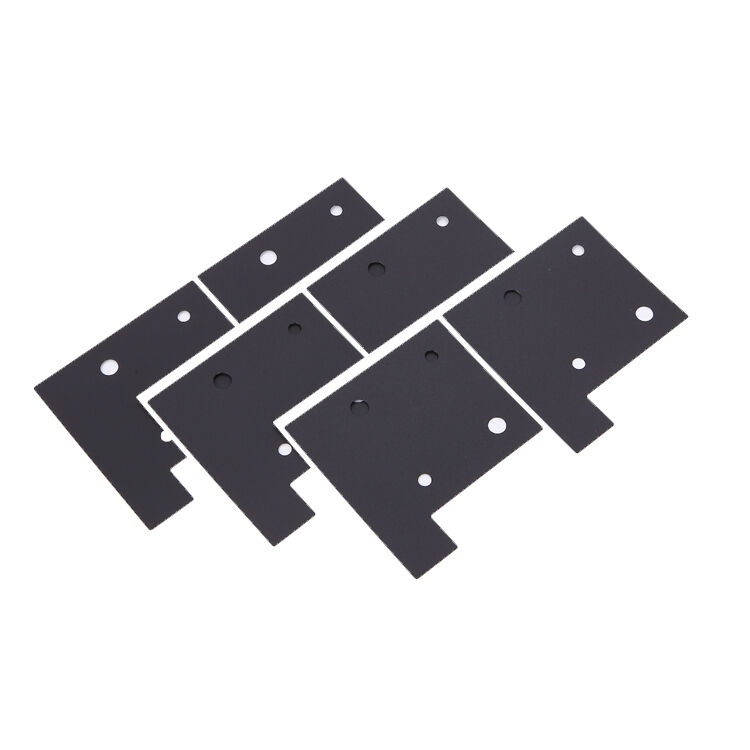

The tape's conformable nature allows it to adapt to various surface textures and geometries, making it suitable for complex three-dimensional applications. This flexibility enables effective sealing around cable entry points, connector interfaces, and other critical areas where electromagnetic leakage commonly occurs. The material's ability to maintain intimate contact with substrate surfaces ensures consistent shielding performance across the entire protected area.

Installation versatility extends to compatibility with various substrate materials commonly found in electronic assemblies. The adhesive bonds effectively to metals, plastics, and composite materials, providing engineers with flexibility in design implementation. This broad compatibility reduces the need for surface preparation in many applications, accelerating installation processes while maintaining reliable performance.

Applications & Use Cases

The Copper Foil Tape Conductive Adhesive for EMI Shielding and Electrical Grounding serves critical functions across numerous industries where electromagnetic compatibility represents a fundamental design requirement. Telecommunications equipment manufacturers rely on this shielding solution to protect sensitive receiver circuits from interference while maintaining signal integrity in high-frequency applications. The tape's ability to provide consistent shielding performance makes it particularly valuable in base station equipment and network infrastructure components where electromagnetic compatibility directly impacts system performance.

Automotive electronics applications benefit significantly from the tape's robust construction and environmental resistance. Modern vehicles incorporate numerous electronic control units that must operate reliably in electromagnetically challenging environments while meeting strict regulatory requirements. The copper foil tape provides effective shielding for engine management systems, infotainment units, and advanced driver assistance systems, ensuring proper functionality throughout the vehicle's operational lifetime.

Medical device manufacturers utilize this shielding solution to protect sensitive diagnostic and therapeutic equipment from electromagnetic interference that could compromise patient safety or measurement accuracy. The tape's reliability and consistent performance characteristics make it suitable for critical medical applications where electromagnetic compatibility represents both a regulatory requirement and a patient safety imperative.

Consumer electronics applications span from mobile devices to home appliances, where the tape provides cost-effective electromagnetic shielding while meeting increasingly stringent regulatory requirements. The material's ease of application makes it particularly suitable for high-volume manufacturing processes while maintaining the performance consistency required for global market compliance.

Industrial automation and control systems rely on electromagnetic shielding to maintain reliable operation in electrically noisy industrial environments. The copper foil tape provides effective protection for programmable logic controllers, variable frequency drives, and sensor interfaces where electromagnetic interference could disrupt critical process control functions.

Quality Control & Compliance

Our manufacturing processes incorporate comprehensive quality assurance protocols that ensure every roll of Copper Foil Tape Conductive Adhesive for EMI Shielding and Electrical Grounding meets stringent performance standards. Quality control begins with incoming material inspection, where copper foil thickness uniformity and surface quality undergo rigorous evaluation. The conductive adhesive receives similar scrutiny, with electrical resistance measurements and adhesion strength testing performed on representative samples from each production batch.

Environmental testing protocols simulate real-world operating conditions to validate long-term performance characteristics. Temperature cycling, humidity exposure, and mechanical stress testing ensure the tape maintains its shielding effectiveness and adhesive properties throughout its intended service life. These comprehensive testing procedures provide confidence in product reliability across diverse application environments.

Compliance with international electromagnetic compatibility standards represents a fundamental aspect of our quality commitment. The tape's shielding effectiveness undergoes verification testing according to recognized industry standards, ensuring customers can rely on documented performance data for their regulatory compliance requirements. This testing includes frequency response characterization and shielding effectiveness measurements across relevant frequency ranges.

Traceability systems maintain detailed records of material sources, production parameters, and test results for each manufactured batch. This documentation supports customer quality requirements while enabling rapid response to any performance inquiries or application-specific questions that may arise during product implementation.

Customization & Branding Options

Understanding that diverse applications require specialized solutions, we offer extensive customization capabilities for our Copper Foile Tape Conductive Adhesive for EMI Shielding and Electrical Grounding. Width customization accommodates specific application requirements, from narrow strips suitable for cable wrapping to broader formats designed for large-area shielding applications. This flexibility eliminates waste while ensuring optimal coverage for each unique application scenario.

Adhesive formulation variations address specific environmental requirements or substrate compatibility needs. Modified adhesives can provide enhanced temperature resistance, improved chemical compatibility, or specialized bonding characteristics for challenging surface materials. These customization options ensure optimal performance across diverse application environments while maintaining the fundamental shielding and grounding capabilities that define the product.

Private labeling services support customer branding requirements while maintaining our quality standards throughout the manufacturing process. Custom packaging options can incorporate customer logos, part numbers, and specification information to support inventory management and quality traceability systems. These branding services extend to packaging design, where custom printing and labeling can reinforce brand identity while providing essential product information.

Technical consultation services assist customers in optimizing product specifications for their specific applications. Our engineering team collaborates with customers to evaluate performance requirements, environmental conditions, and installation procedures to recommend optimal product configurations. This collaborative approach ensures maximum value from the shielding solution while supporting successful implementation across diverse application scenarios.

Packaging & Logistics Support

Comprehensive packaging solutions protect product integrity throughout the distribution chain while supporting efficient handling and storage procedures. Primary packaging utilizes materials specifically selected to prevent adhesive contamination and maintain copper foil surface quality during extended storage periods. Release liner selection ensures easy product handling while preventing premature adhesive activation during shipping and storage.

Secondary packaging incorporates protective measures designed to prevent physical damage during transportation while maintaining product identification and traceability information. Moisture barrier properties protect the conductive adhesive from environmental degradation that could compromise electrical performance. These packaging measures ensure customers receive products in optimal condition regardless of shipping distances or storage duration.

Logistics coordination supports global distribution requirements through established partnerships with international shipping providers. Documentation services ensure compliance with import/export regulations while providing necessary technical data for customs clearance procedures. This comprehensive logistics support minimizes delivery delays while ensuring proper handling throughout the international shipping process.

Inventory management services can accommodate varying order patterns and seasonal demand fluctuations through flexible stocking arrangements. Just-in-time delivery capabilities support lean manufacturing initiatives while maintaining product availability for critical applications. These services reduce customer inventory carrying costs while ensuring reliable product supply for ongoing production requirements.

Why Choose Us

Our extensive experience as a leading metal packaging manufacturer and custom tin box supplier positions us uniquely to understand the electromagnetic shielding requirements across diverse industries. This background provides valuable insights into material selection, manufacturing precision, and quality control procedures that directly benefit our Copper Foil Tape Conductive Adhesive for EMI Shielding and Electrical Grounding customers. Our established reputation for delivering OEM tin packaging solutions demonstrates our commitment to meeting exacting customer specifications while maintaining competitive delivery schedules.

Global collaboration with international partners ensures we remain current with evolving electromagnetic compatibility requirements and emerging application trends. This international perspective enables us to anticipate customer needs while developing innovative solutions that address future market requirements. Our multi-industry expertise spans automotive, telecommunications, medical devices, and consumer electronics, providing comprehensive understanding of diverse application challenges and performance expectations.

As a recognized metal packaging supplier, we bring decades of experience in precision manufacturing and quality control to our conductive tape production. This manufacturing heritage ensures consistent product quality while supporting scalable production capabilities that can accommodate both prototype quantities and high-volume production requirements. Our commitment to continuous improvement drives ongoing investment in manufacturing technology and quality systems that benefit all product lines.

Technical support capabilities extend beyond product supply to include application engineering assistance and performance optimization consultation. Our engineering team collaborates with customers throughout the product selection and implementation process, ensuring optimal results while minimizing development time and costs. This comprehensive support approach reflects our commitment to customer success while building long-term partnerships that benefit both organizations.

Conclusion

The Copper Foil Tape Conductive Adhesive for EMI Shielding and Electrical Grounding represents an essential solution for modern electromagnetic compatibility challenges, combining proven materials science with innovative manufacturing techniques to deliver reliable performance across diverse applications. Its unique combination of electromagnetic shielding effectiveness and electrical grounding capability provides engineers and manufacturers with a versatile tool for addressing increasingly complex electromagnetic interference requirements while maintaining cost-effective implementation strategies.

The product's superior performance characteristics, comprehensive customization options, and robust quality assurance protocols ensure it meets the demanding requirements of industries ranging from telecommunications to medical devices. Our commitment to continuous improvement and customer support reinforces the value proposition while building confidence in long-term product reliability and supplier partnership stability. This copper foil tape solution stands ready to support the next generation of electronic devices and systems where electromagnetic compatibility represents both a technical challenge and a competitive advantage.

Professional EMI Shielding Tapes - Total Solution for RFI/ESD Protection

Excellent Shielding Performance |

Offers high shielding effectiveness over a wide frequency range, ideal for EMI, RFI, and ESD full protection. |

||||||

High Conductivity & Low Resistance |

Made from superior materials like nickel/copper coated fabric or pure copper foil, ensuring good electrical conductivity and reliable grounding. |

||||||

Flexible & Conformable |

Ultra-thin, flexible, and lightweight design allows for easy application on curved surfaces and tight spaces, such as internal circuit boards and flexible circuits. |

||||||

Customizable Solutions |

Available in custom sizes, shapes, and die-cuts (OEM/ODM supported). RoHS and REACH compliant to meet global environmental standards. |

||||||

Consumer Electronics |

Smartphones, laptops, gaming consoles, LCD displays, and 5G wireless chargers for internal circuit board shielding and high-speed HDMI signal protection. |

||||||

Automotive & Transportation |

Automotive electronics, autonomous vehicles LiDAR/Radar systems, and EV wireless chargers as part of robust EMC solutions. |

||||||

Telecom & Networking |

Networking equipment, 5G infrastructure, and cabinet shielding to ensure signal integrity and prevent interference. |

||||||

Industrial & Medical

|

Industrial control systems, power supplies, and sensitive medical electronic devices requiring reliable performance in demanding conditions. |

||||||

Available Types

Company Profile

We cater primarily to the consumer electronics, communication networks, and emerging energy vehicle sectors. To back ourcommitment to quality and innovation, we have established a national production base across four strategic locations:

1. A 1,000-square-meter new material formula R&D center in Shenzhen.

2. A 2,000-square-meter innovative grounding wrapping production plant in Dongguan.

3. A 10,000-square-meter conductive shielding tape coating plant in Hunan.

4. A 1,000-square-meter magnetron sputtering continuous gold/tin plating plant in Shandong.

As the only vertically integrated integrator in China offering electroplating, coating, and processing capabilities, we strive to become a leading innovator and provider of core values within the materials industry chain. Our ultimate goal is to be a long-term trusted solution provider and partner for our customers in addressing their challenges.

Invention Patent

System certification

FAQ

We are based in Guangdong, China, start from 2011,sell to South Asia(10.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Shielding tape,Adhesive tapes,Waterproof and breathable membrane,Customized production,Raw material die-cutting

4. why should you buy from us not from other suppliers?

Shenzhen Johan Material Tech Co., Ltd. was established in 2011, and is an innovative national high-tech enterprise providing

innovative EMC (electromagnetic compatibility) grounding elastomers and customized tape solutions for the electronics indus

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency: USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken: English,Chinese